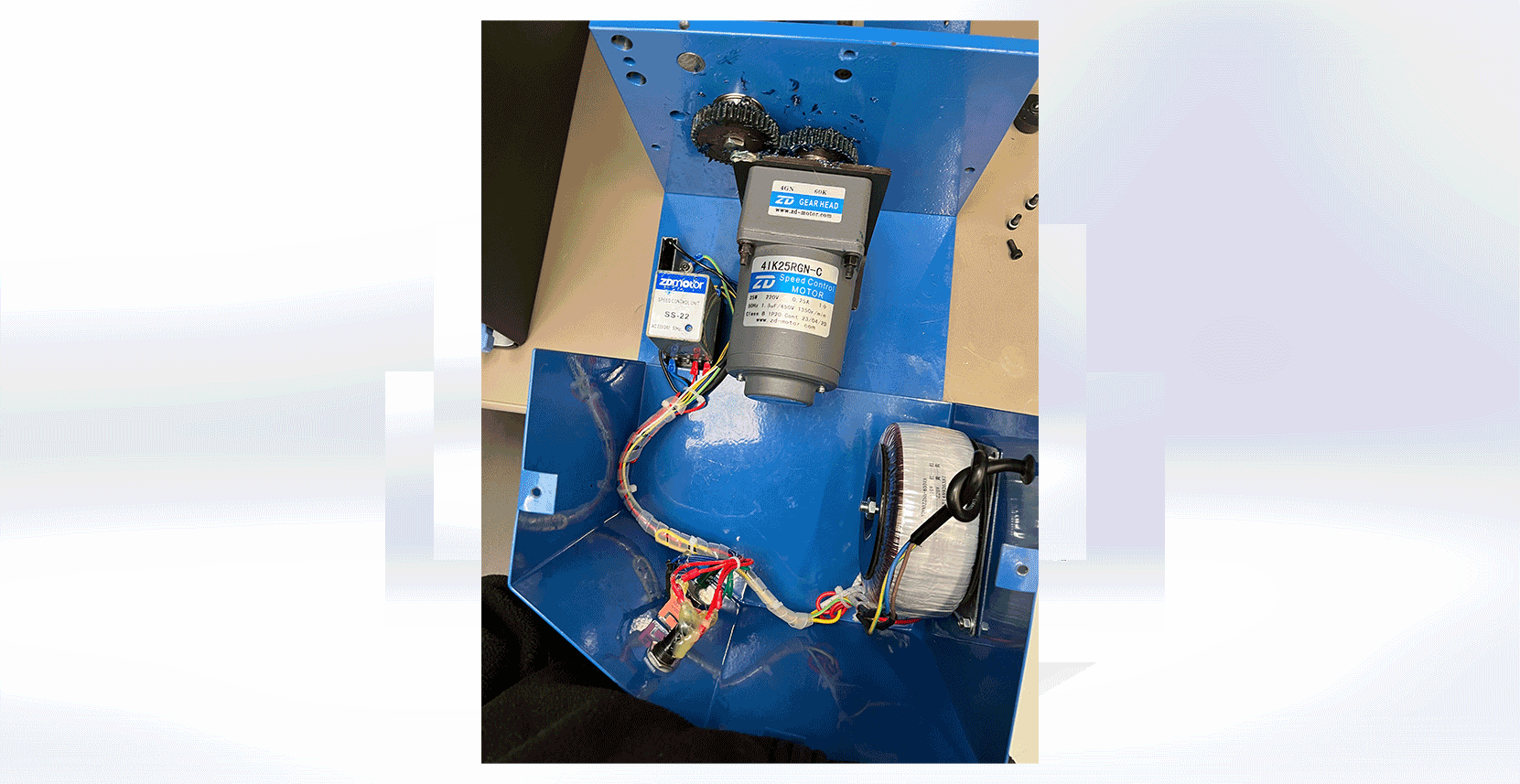

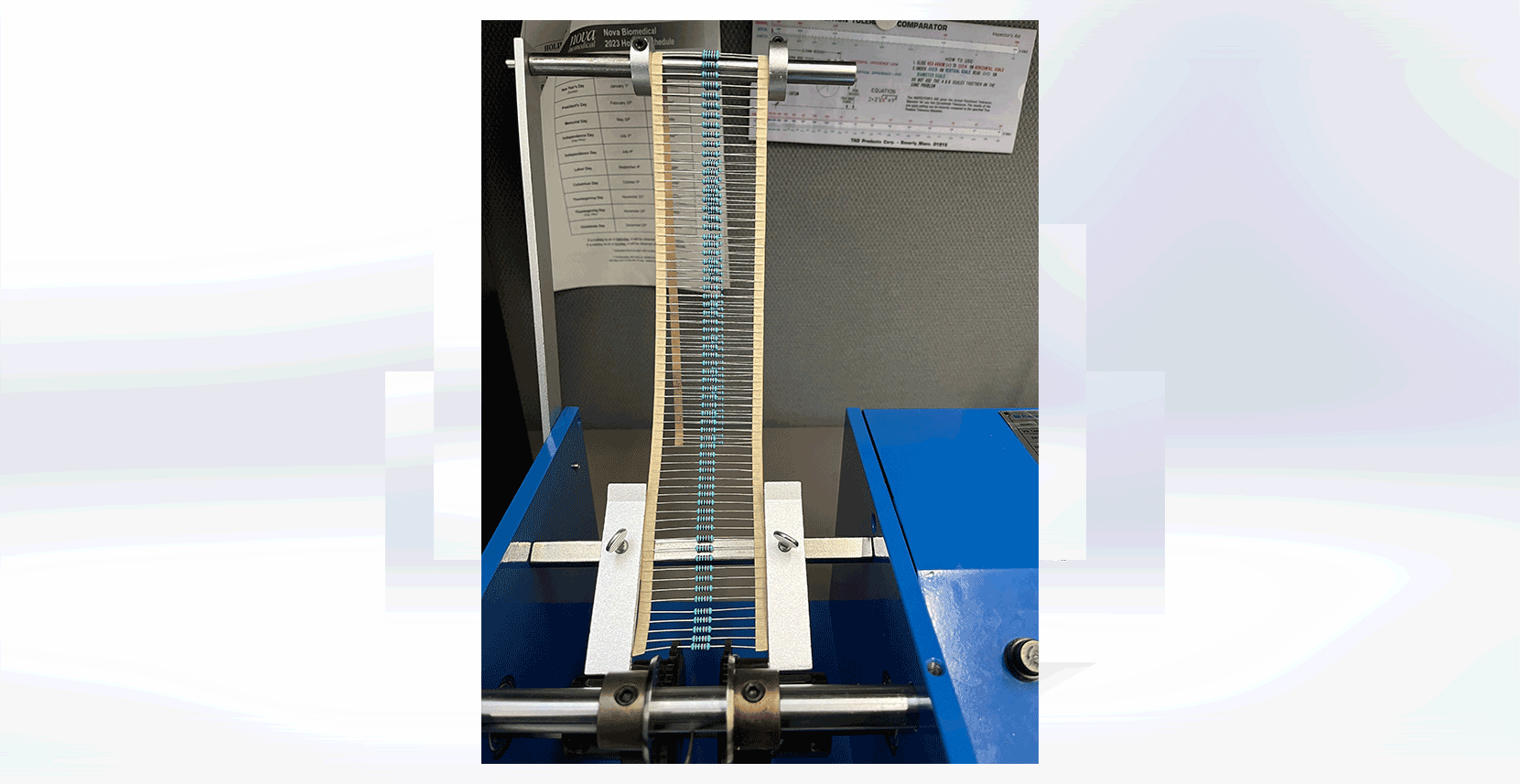

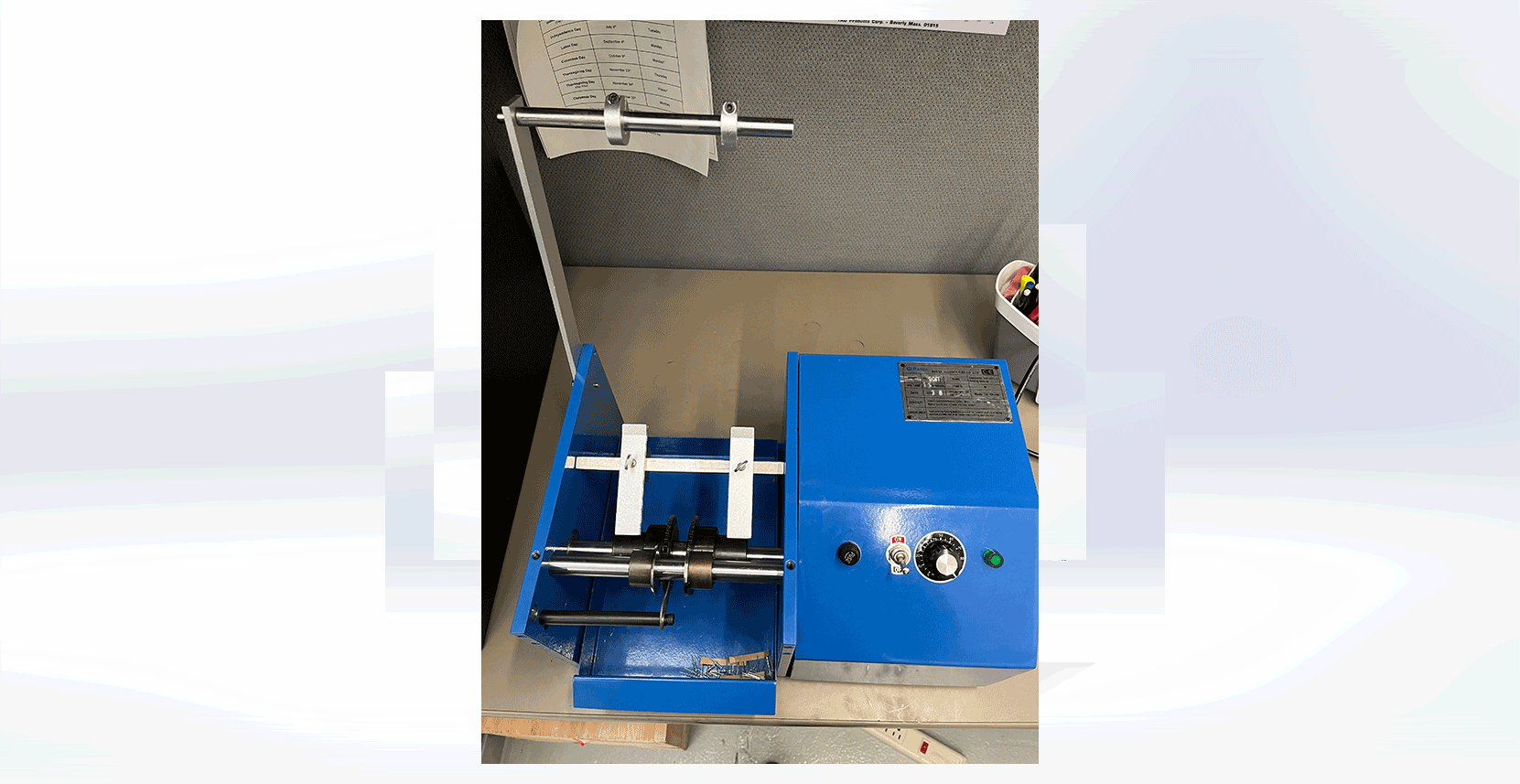

In the latter part of my co-op, I addressed the manual cutting challenges in the sensors and tubing department by introducing an automated solution – the RS-904I resistor cutter from RKens. Assembling the device with RKens' components, I developed operating instructions, a maintenance procedure, and conducted preventative measures. After validating its performance, I initiated the training of department employees on its usage. The automated resistor cutter not only reduces wrist fatigue but also enhances overall efficiency in resistor lead cutting processes, marking a significant improvement in the department's workflow.

Nova Biomedical Co-Op

Home » Nova Biomedical Co-Op

Nova Biomedical Co-Op

I worked at Nova Biomedical as a Manufacturing Engineer from June 2023 to December 2023. During my time at Nova, I got assigned a lot of short term and long term projects that involved a lot with large CAD assemblies, 3D printed and machined new parts and reversed engineered parts, and a lot of testing and working with electronics. I also did a lot of documentation work regarding engineering changing orders, design reviews and design for manufacturing, operating instructions, and drawings. Here is some of the work I have done.

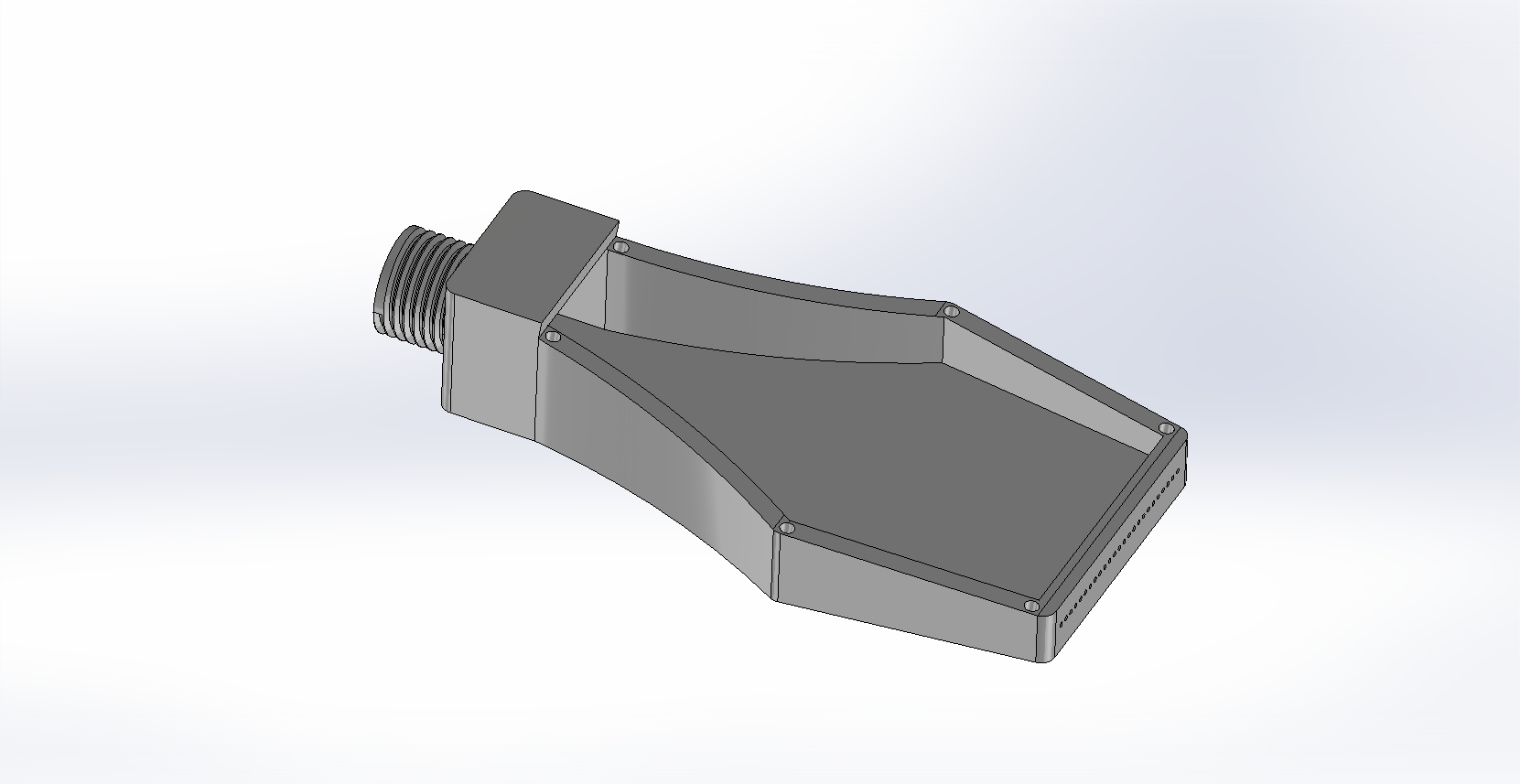

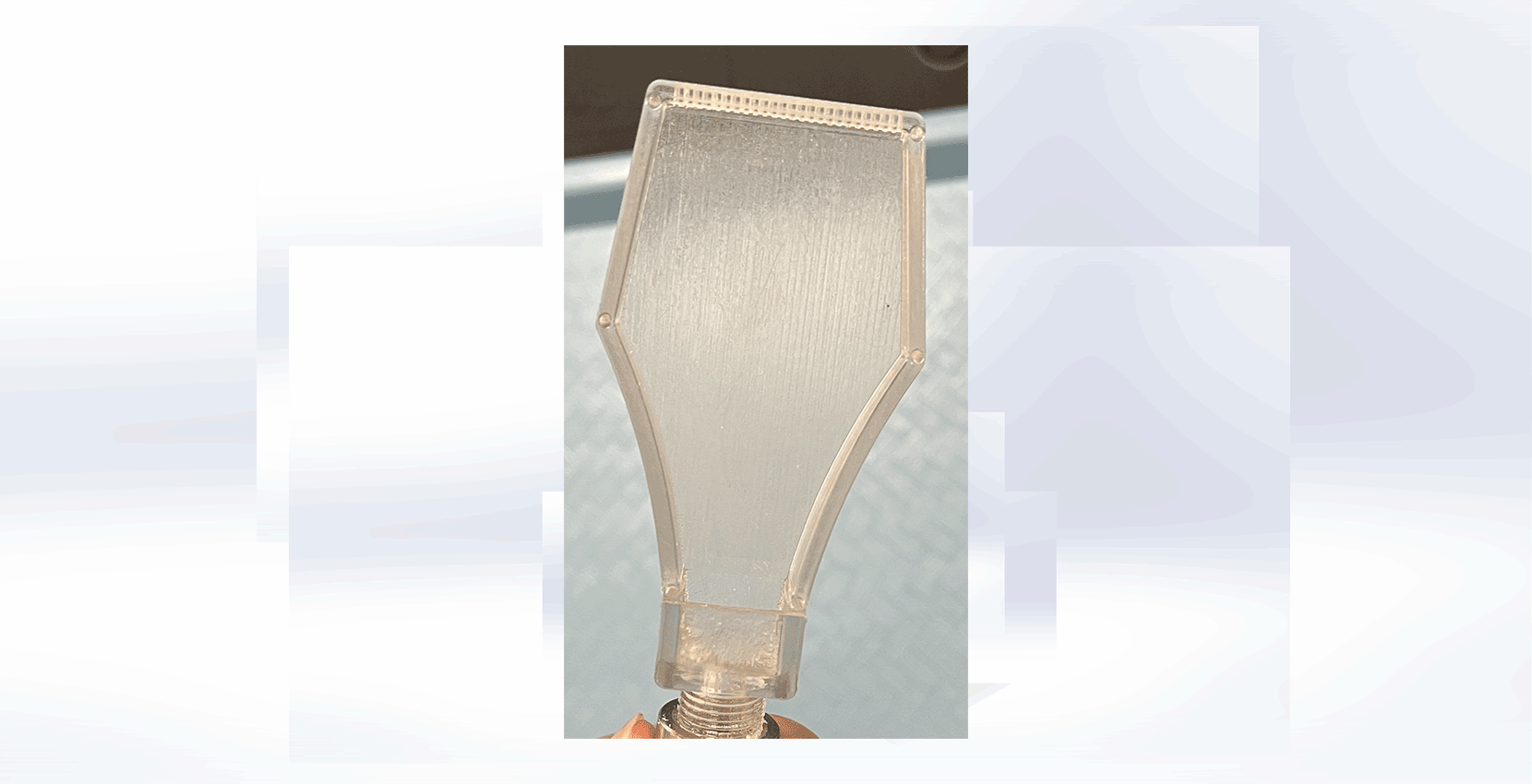

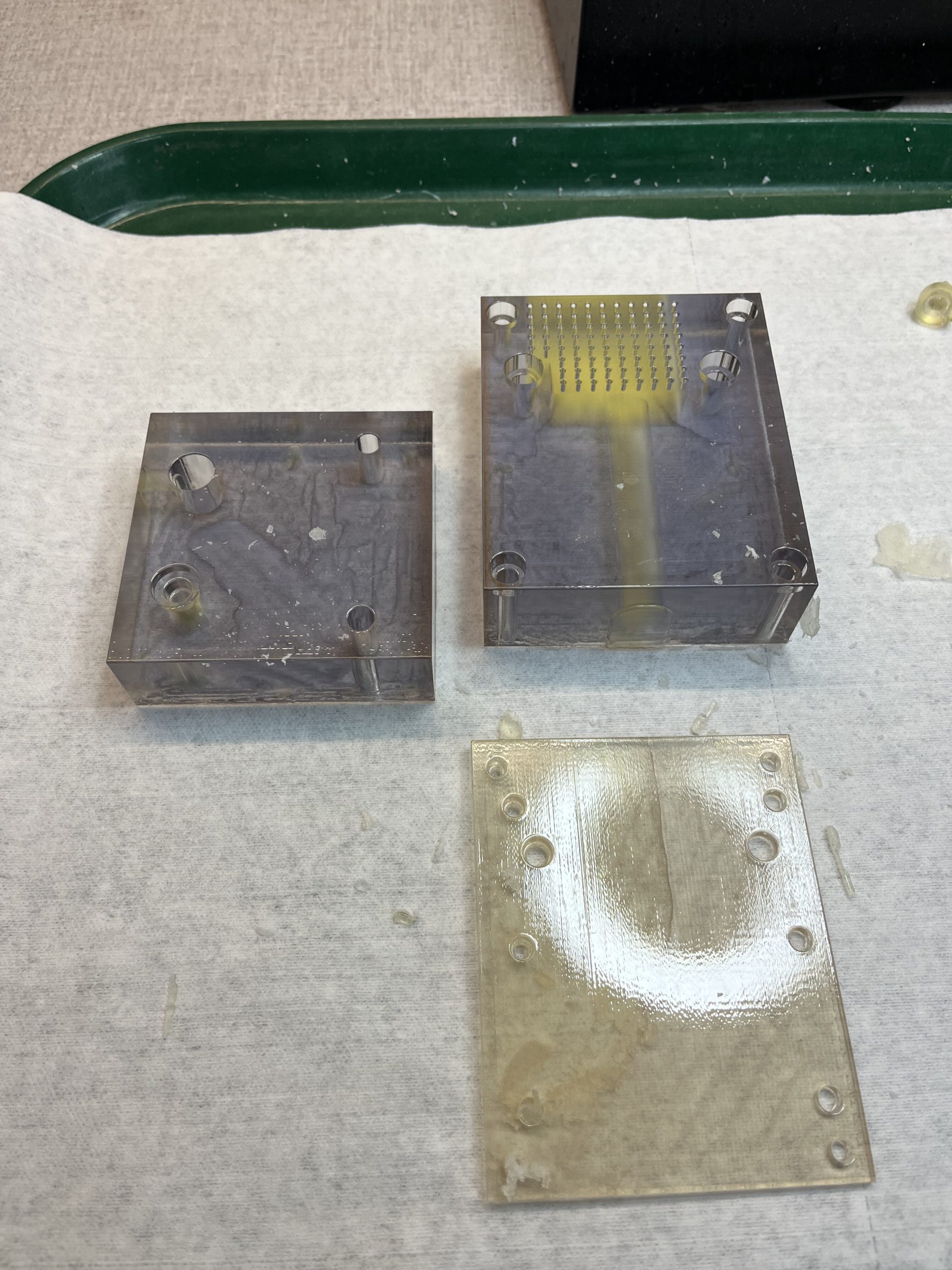

Objective:

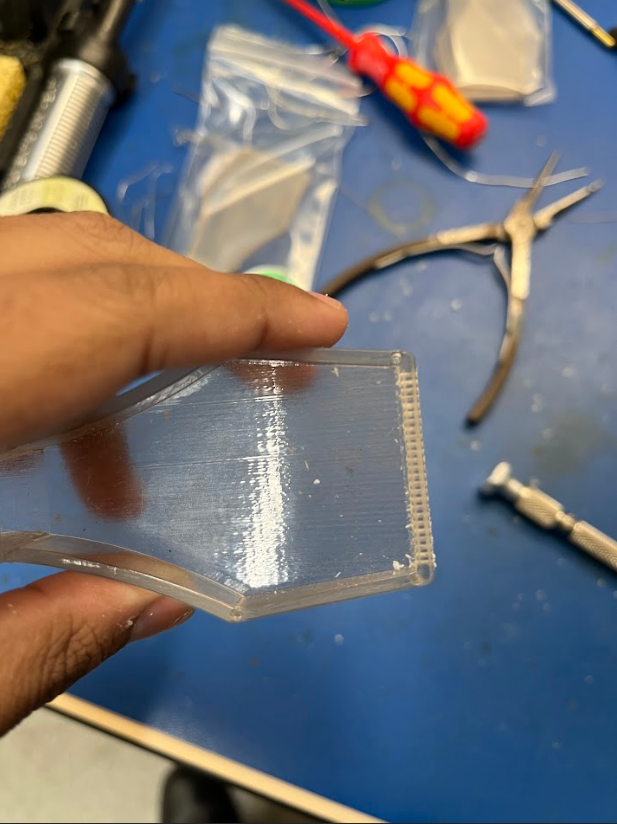

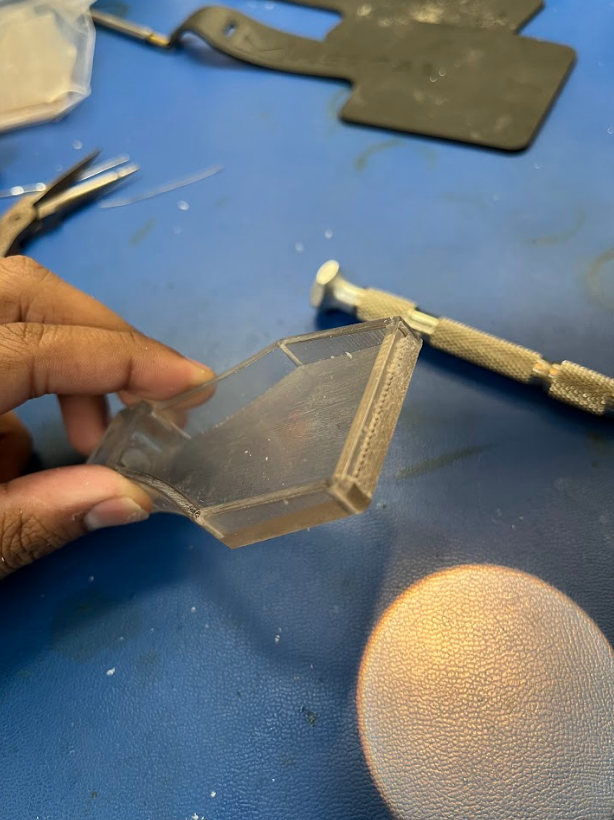

I was assigned to improve the cleaning process for engineer technicians who use methanol to clean parts. The challenge was that existing plastic nozzles limited the diameter of the exit holes, affecting the cleaning efficiency. To address this, I designed an acrylic 3D printed nozzle with smaller exit hole diameters (0.025 inch) to enable faster methanol flow and enhance the cleaning effectiveness.

Acrylic Nozzle Structure

● 3D printer’s limitations prevent creating a single hollow part.

● Workaround required for internal support coverage.

● Using SolidWorks, the nozzle is designed as two separate parts to overcome printing

constraints.

● Parts seamlessly assembled through screws and epoxy.

Fluid Dynamics Optimization

● 0.025 inch diameter holes demand careful design to enhance methanol flow.

● Flow dynamics measured in standard cubic feet per minute (SCFM).

● Modeled the nozzle with a curved and inclined shape for enhanced fluid flow.

● Symmetrical screw holes at corners of nozzle for polished design.

Printing Precision

● The polyjet 3D printer can create markings for 0.025 inch circles but are not precise enough to make holes with support.

● Positioned holes above lower interior base

● Manually drilled 25 openings using microscope and 0.025-inch drill bit after 3D printer marked hole positions.

System Integration

● Threads must be incorporated to ensure the nozzle fits seamlessly with the pneumatic cleaning tube.

● This will ensure compatibility with the overall cleaning system.

● Tapped threads to the end of the nozzle and wrapped Teflon tape to ensure a leak-free connection.

● This guarantees a smooth transfer of methanol from the pneumatic tube to the nozzle.

Result

I verified this using a flow meter and collected the data, which clearly indicates superior performance compared to the old nozzle. The information has been organized and documented in Excel. Detailed drawings are provided for easy replication by other engineers.

Objective:

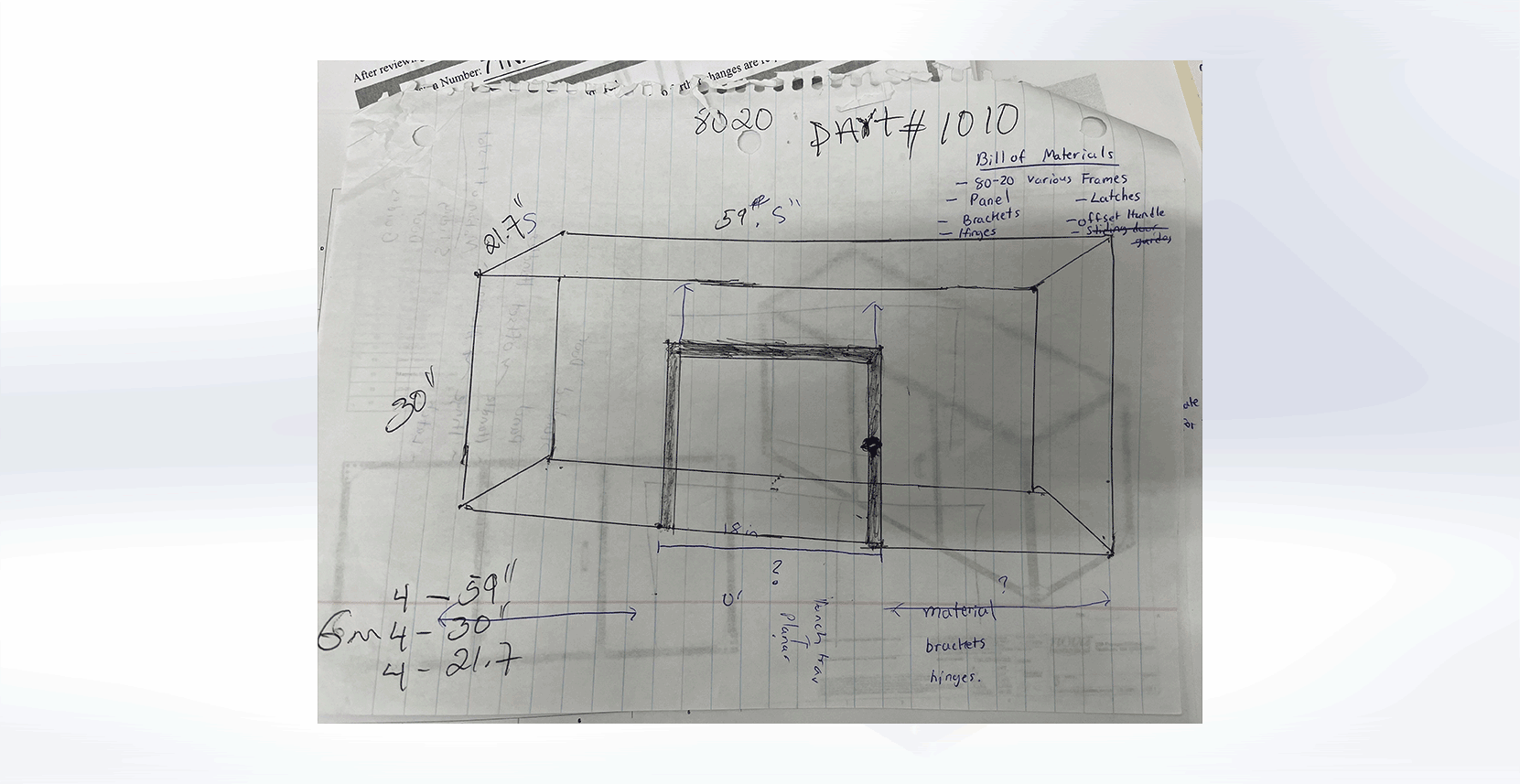

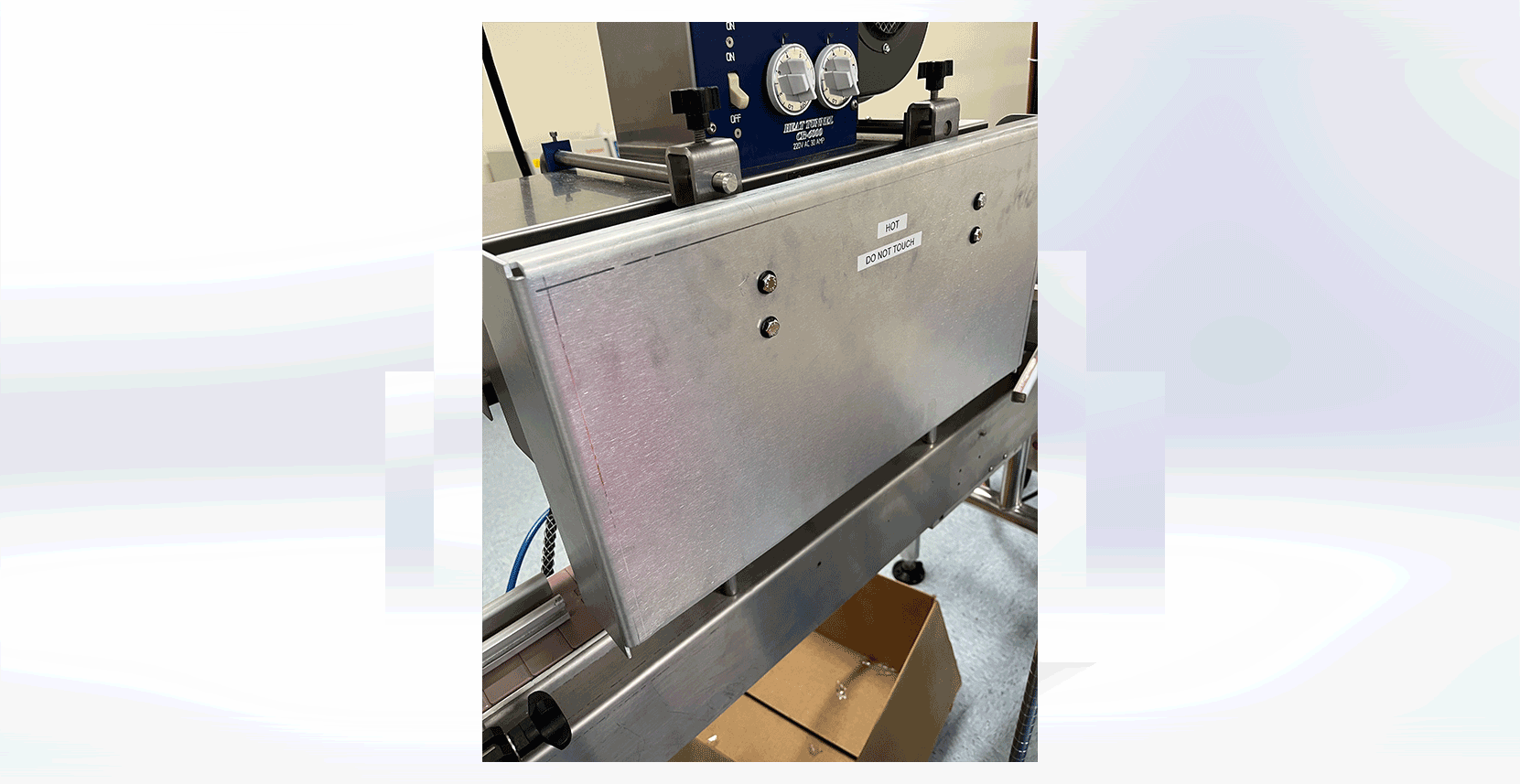

Collaborating with an engineer technician, I received a sketch for developing a drying guard for a conveyor belt system. Typically, a tray with chemicals moves on the conveyor, and air knives clean surface particles. Despite the effectiveness of the air knives, external materials often interfere during the cleaning of chemical parts. I was assigned the task of designing a dryer guard with a door mechanism to seamlessly insert the chemical tray onto the conveyor belt while preventing the ingress of external contaminants.

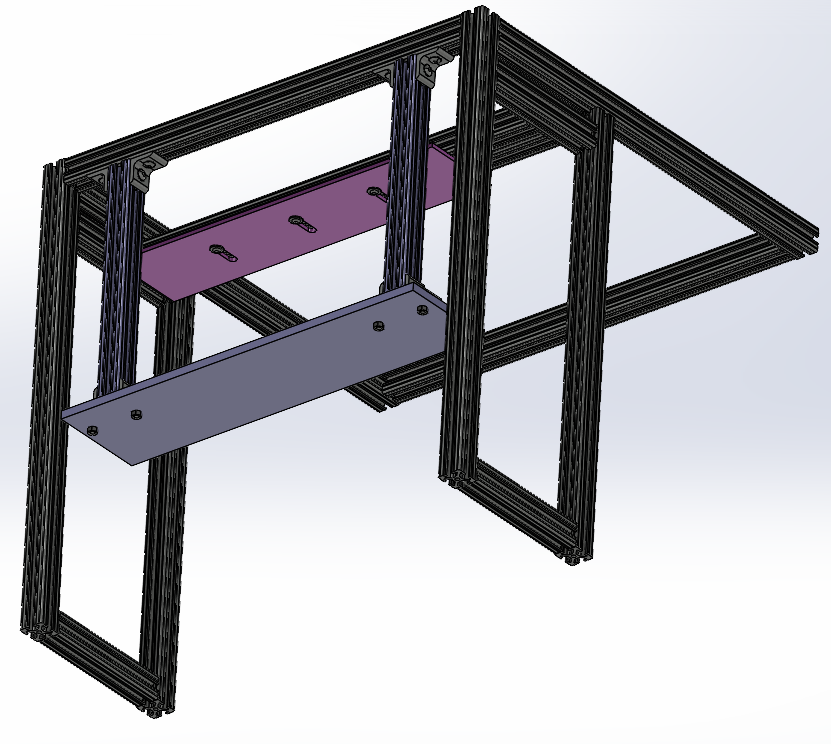

Conveyor Belt for Dryer Guard

Old Dryer Guard Design

Updated Dryer Guard Design

Initial Dryer Guard Sketch

Weight Distribution & Support Structure

● Integrating heavy 80-20 framing onto the dryer guard poses concerns about stress on the conveyor belt.

● Utilize 1015 series T-slots flush-mounted onto the conveyor edges.

● Reinforced with extended extrusions and additional base layer T-slots.

● Employed corner brackets and surface brackets for enhanced support between T-slots.

Air Knife Mounting

● Relocating the air knives due to the replacement of their current mounting place with 80-20 T-slots.

● Implemented pipe clamps assembled onto T-slots in the interior of Dryer Guard.

● Eliminates the need for additional hole drilling and ensures stability for air knives.

Door Design Complexity

● Designing a door that accommodates the tray size and strategically placing holes for hinges, handle, and magnetic latches.

● Cost effective hinges for T-slot mounting and six left side tapped holes on clear polycarbonate lexan panel (serving as door).

● Utilized flexible and angle mates on SolidWorks to facilitate smooth door motion.

● Tapped holes placed on the right side of the door for the magnet and door handle. Magnetic latch assembled onto T-slot without additional drilling.

Transportation Difficulty

● The added weight to the conveyor makes transportation challenging, particularly with its existing footing.

● Added casters with brakes threaded onto T-slots.

● Help facilitate easier movement of the conveyor belt with the dryer guard.

Hardware Acquisition

● Acquring the correct hardware becomes challenging, with most assembly work delegated to another engineer

● Collaborated with NEFF application engineers to ensure comprehensive hardware

acquisition and a guide provided for assembly by other Nova engineers.

● Hardware includes T-nuts, gaskets, brackets, pipe clamps, door handle, hinges, fasteners, and magnetic latch.

Result

After obtaining a quote and creating a purchase order for parts, my final contributions included providing the next steps for the engineering technician and my supervisor to seamlessly carry forward and complete this project. The design, validated by NEFF engineers and my collaborators, is now poised for successful realization.

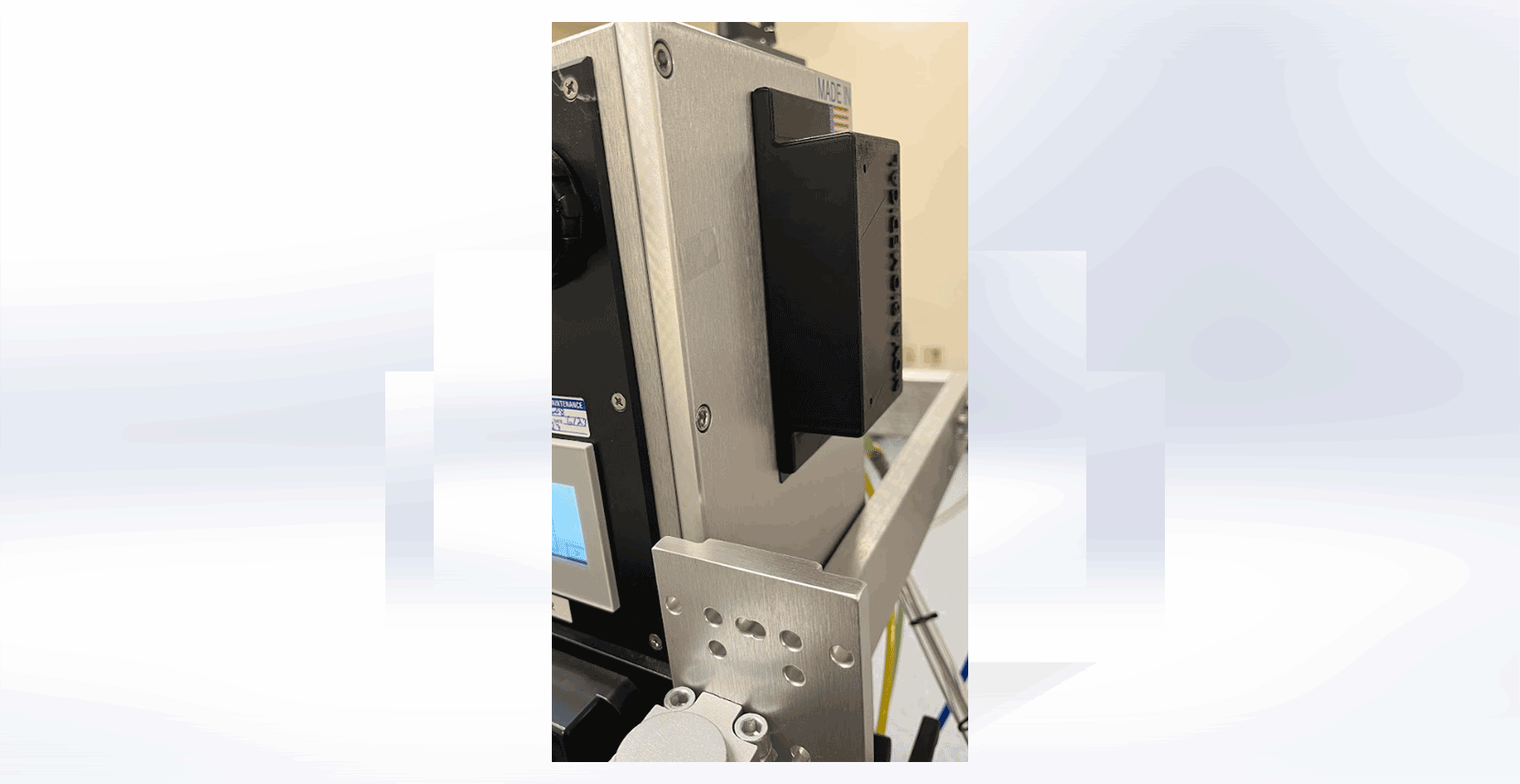

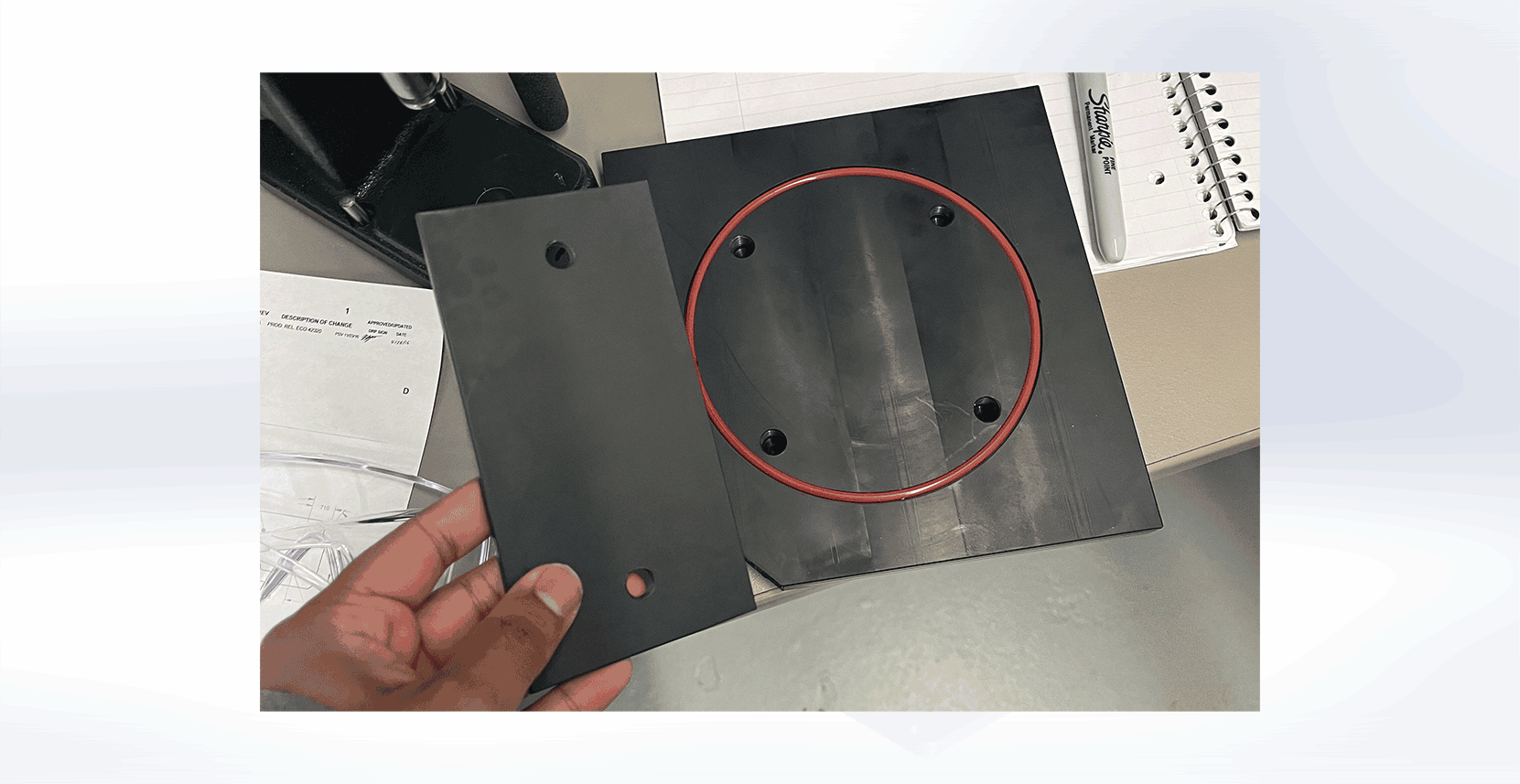

Objective:

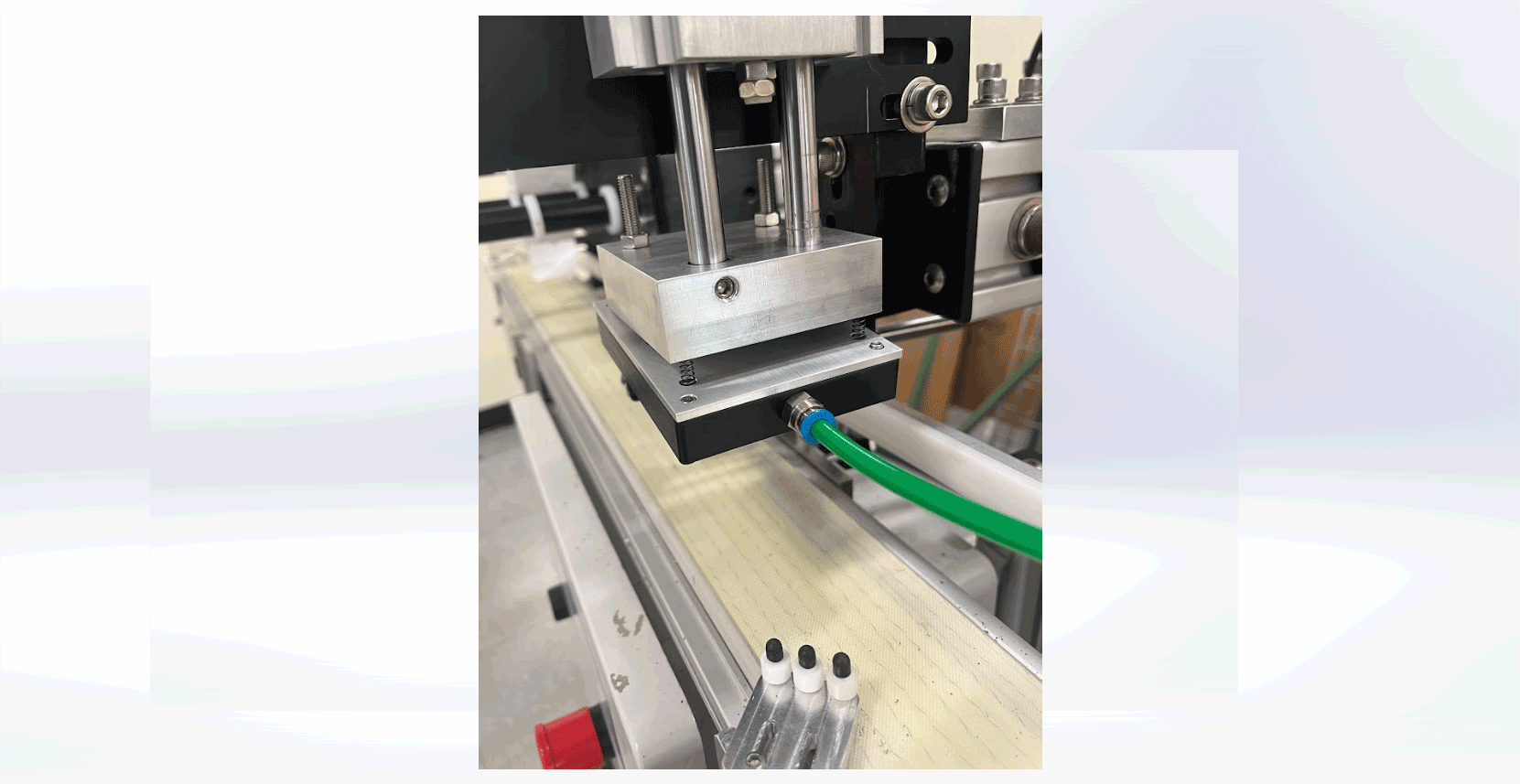

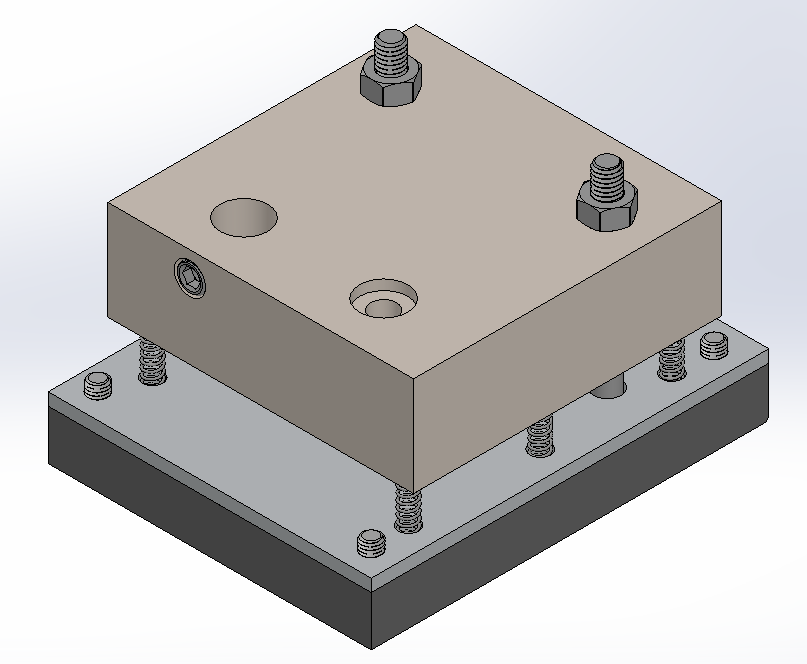

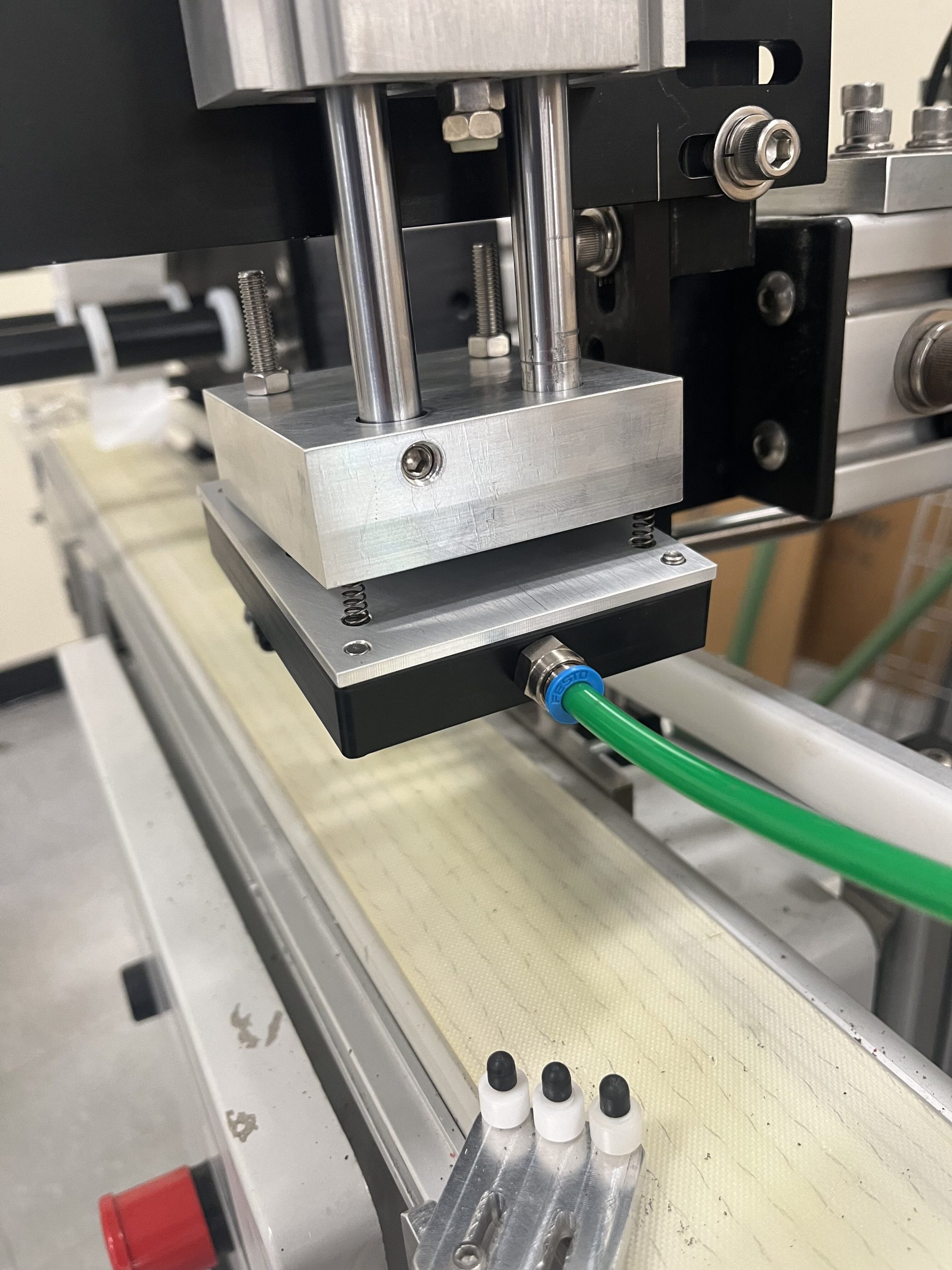

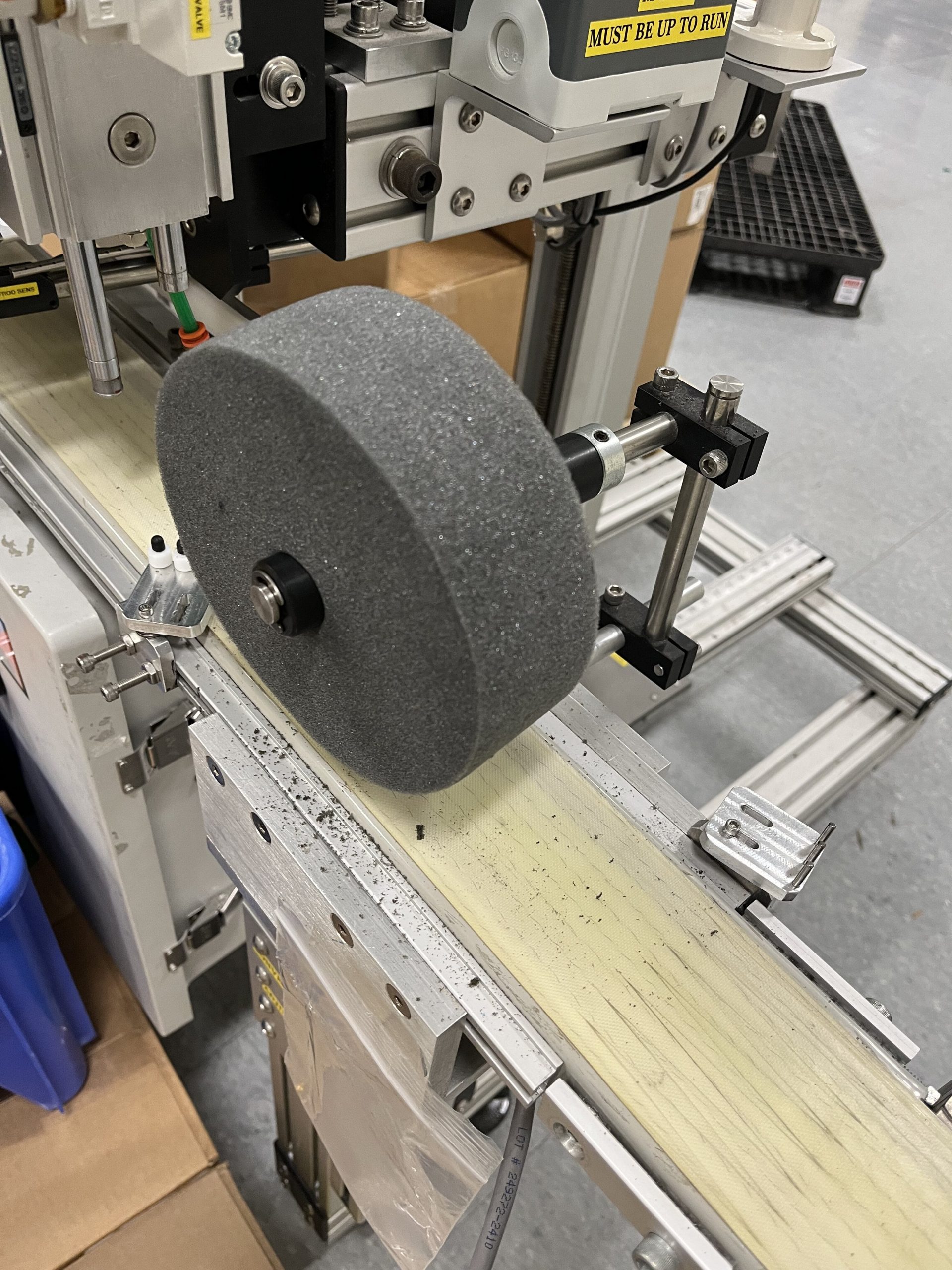

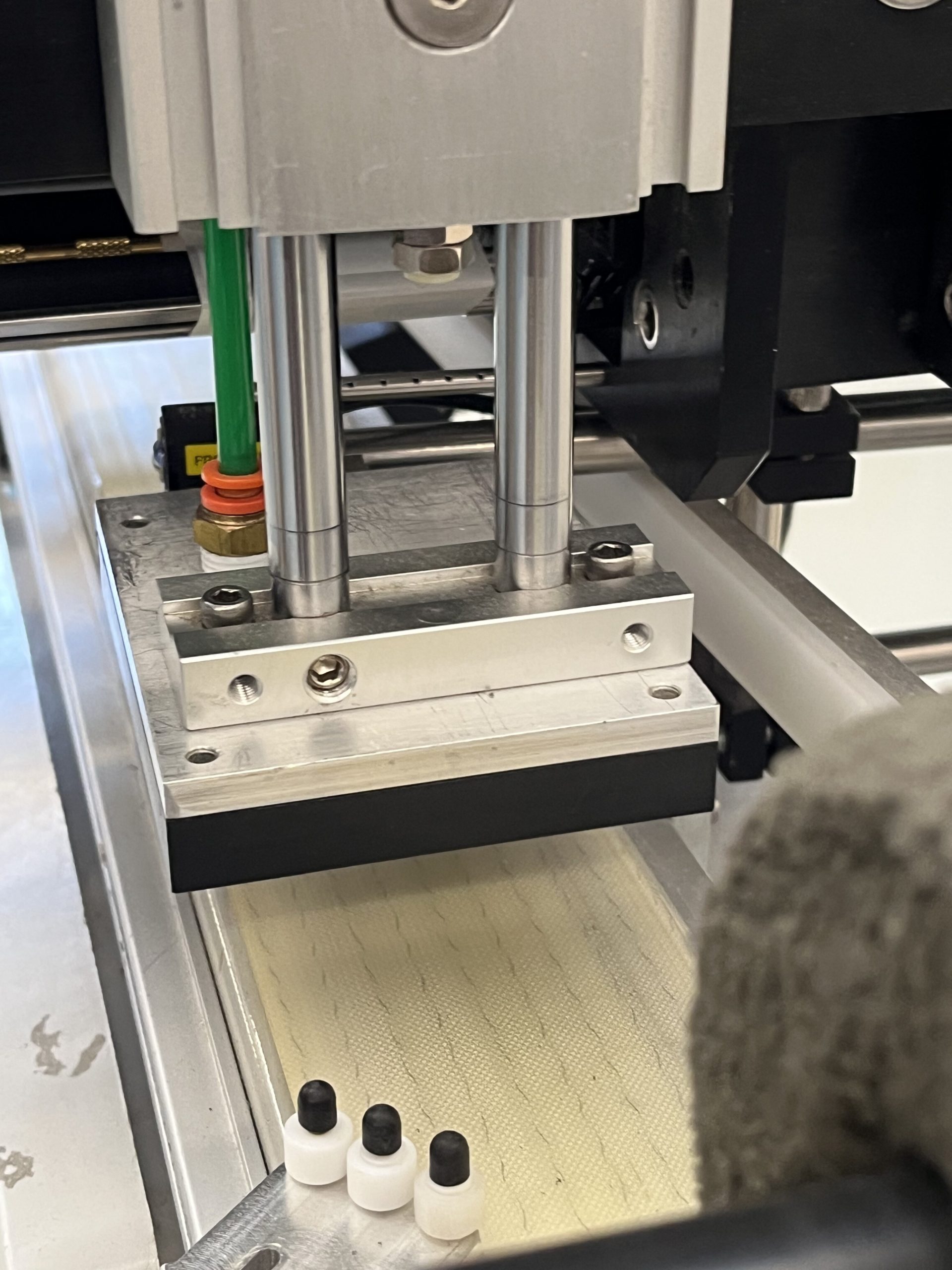

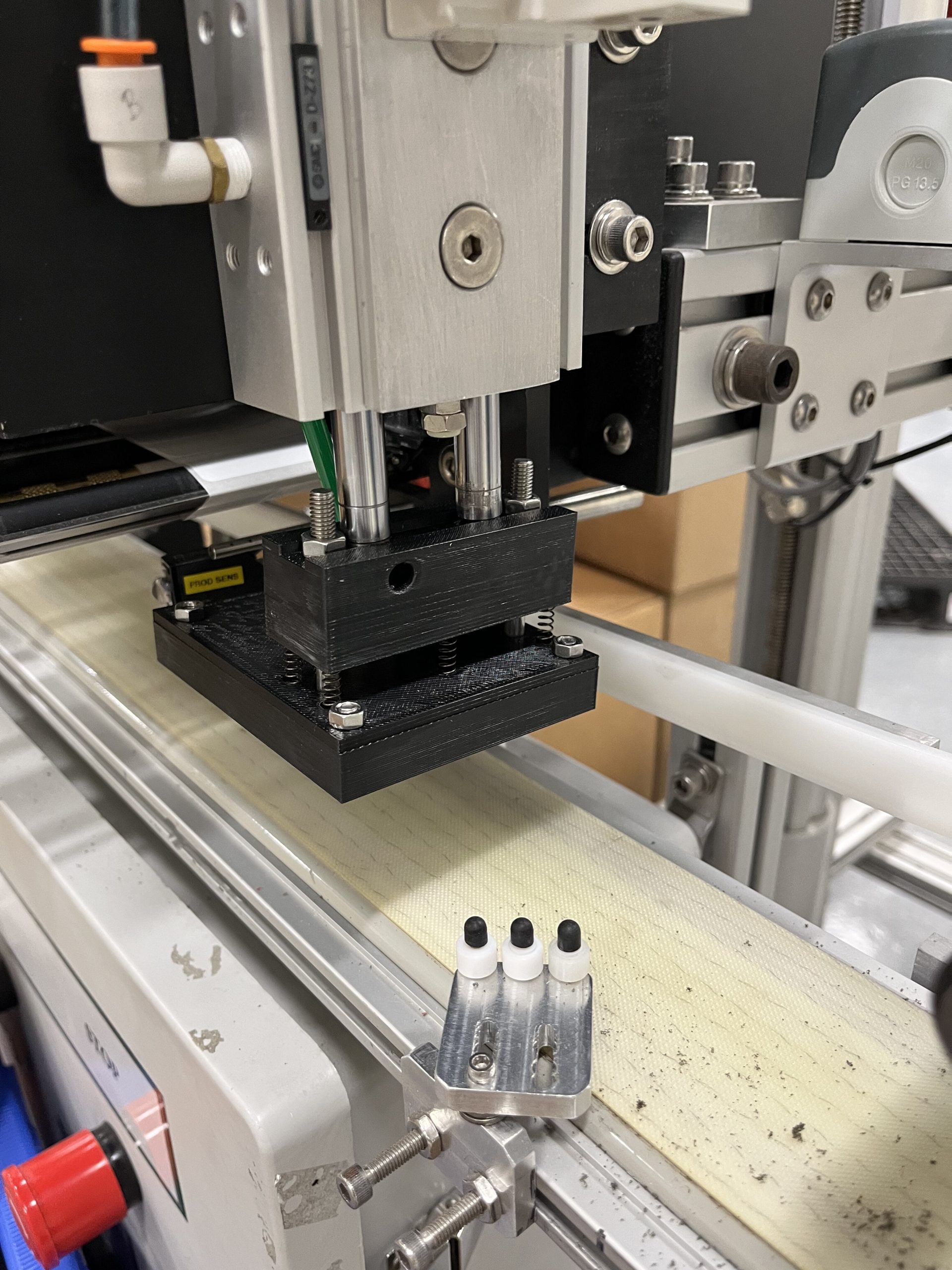

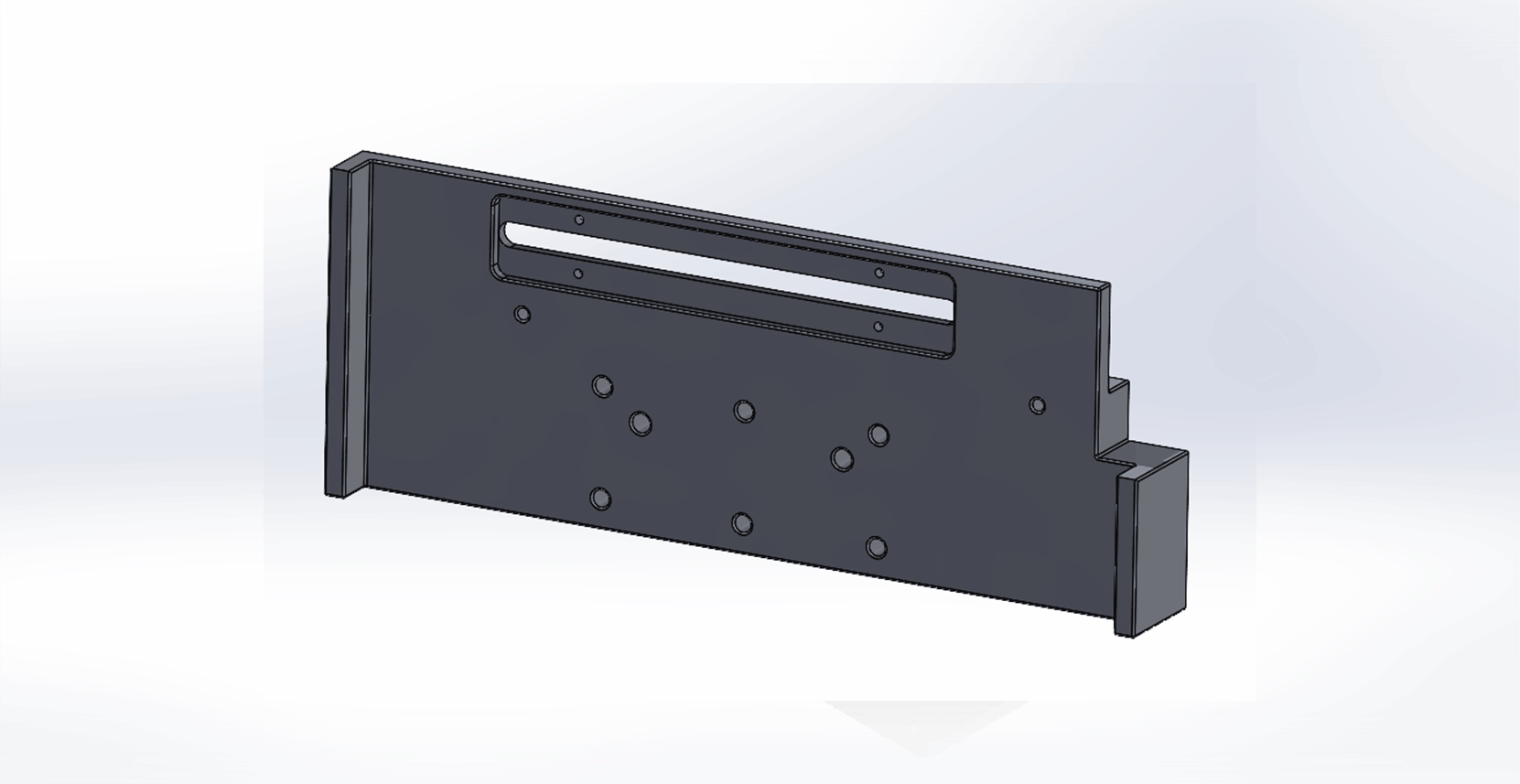

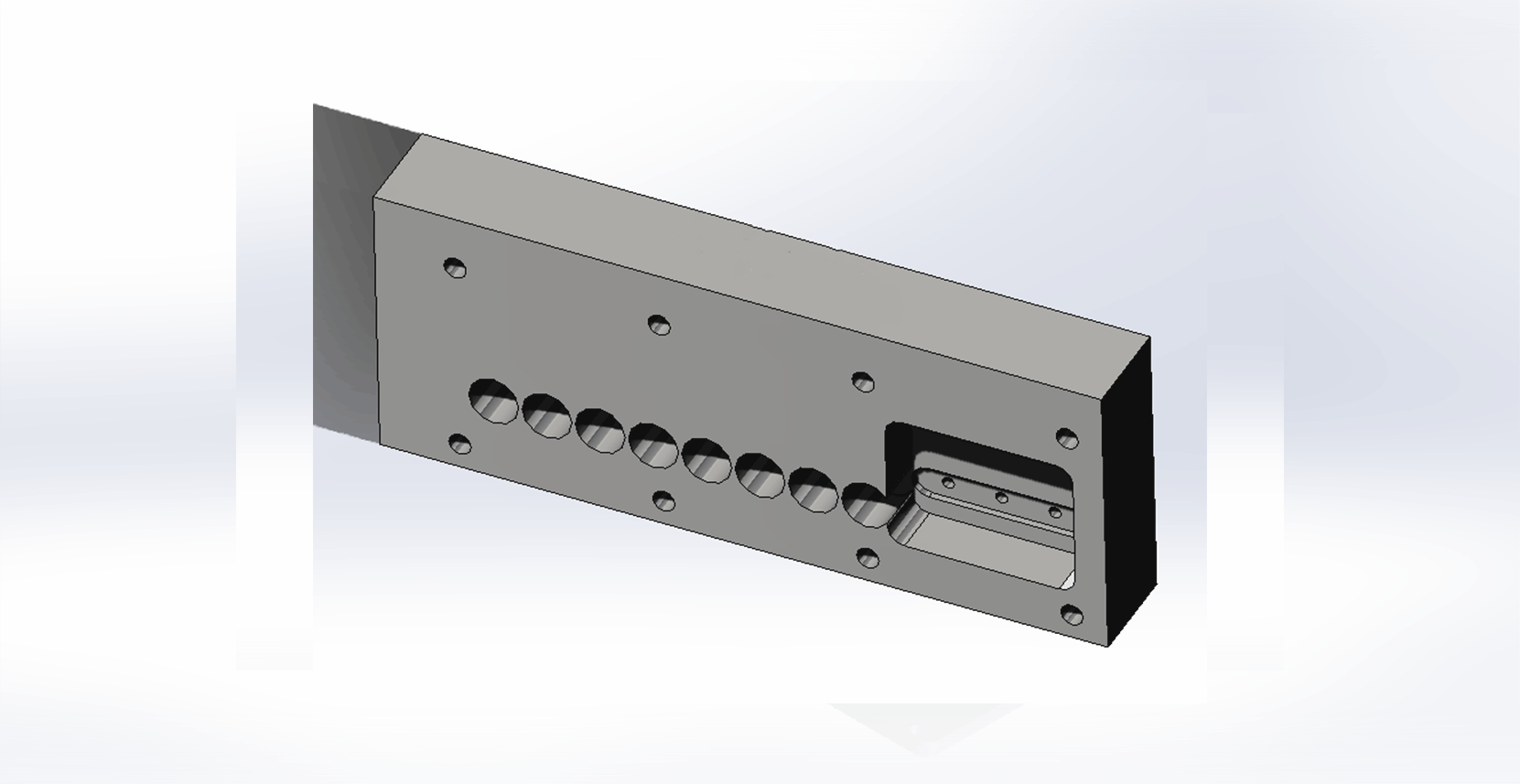

Andrew Sozio and I, the co-op members in charge of manufacturing, have been given the task of upgrading the label press on one of the Allegro label machines. The current label machine is causing damage to packages during the labeling process, and the new labels being used are not compatible with the existing press. Our objective is to design a new label press that preserves the functionalities of the old press while preventing damage to Allegro packaging.

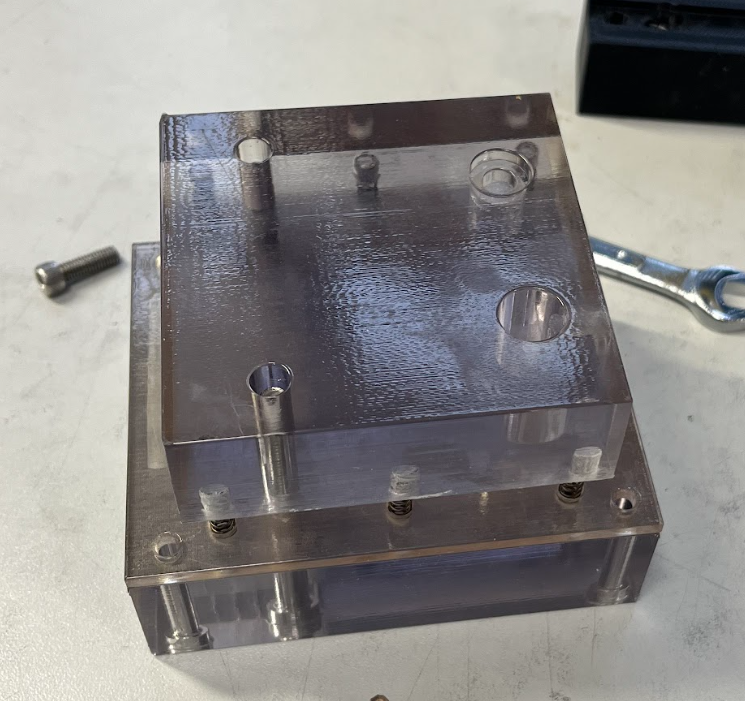

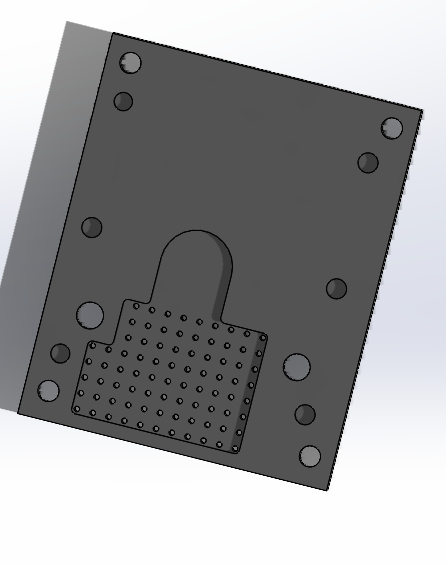

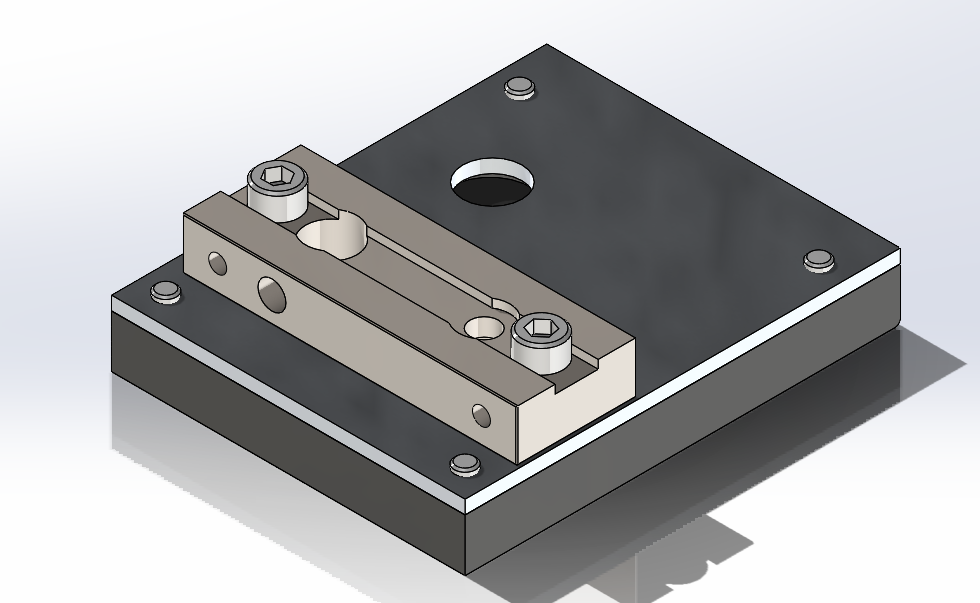

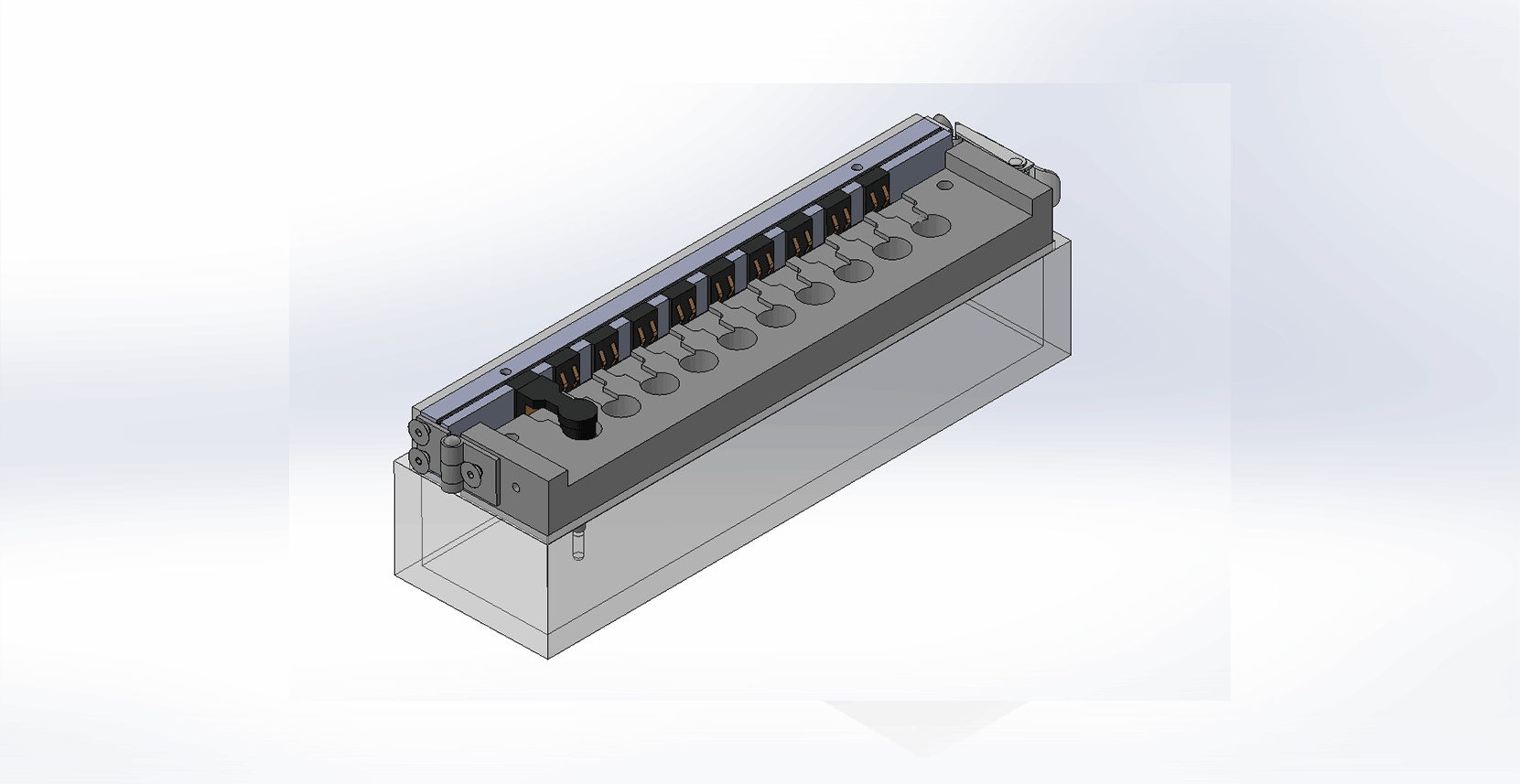

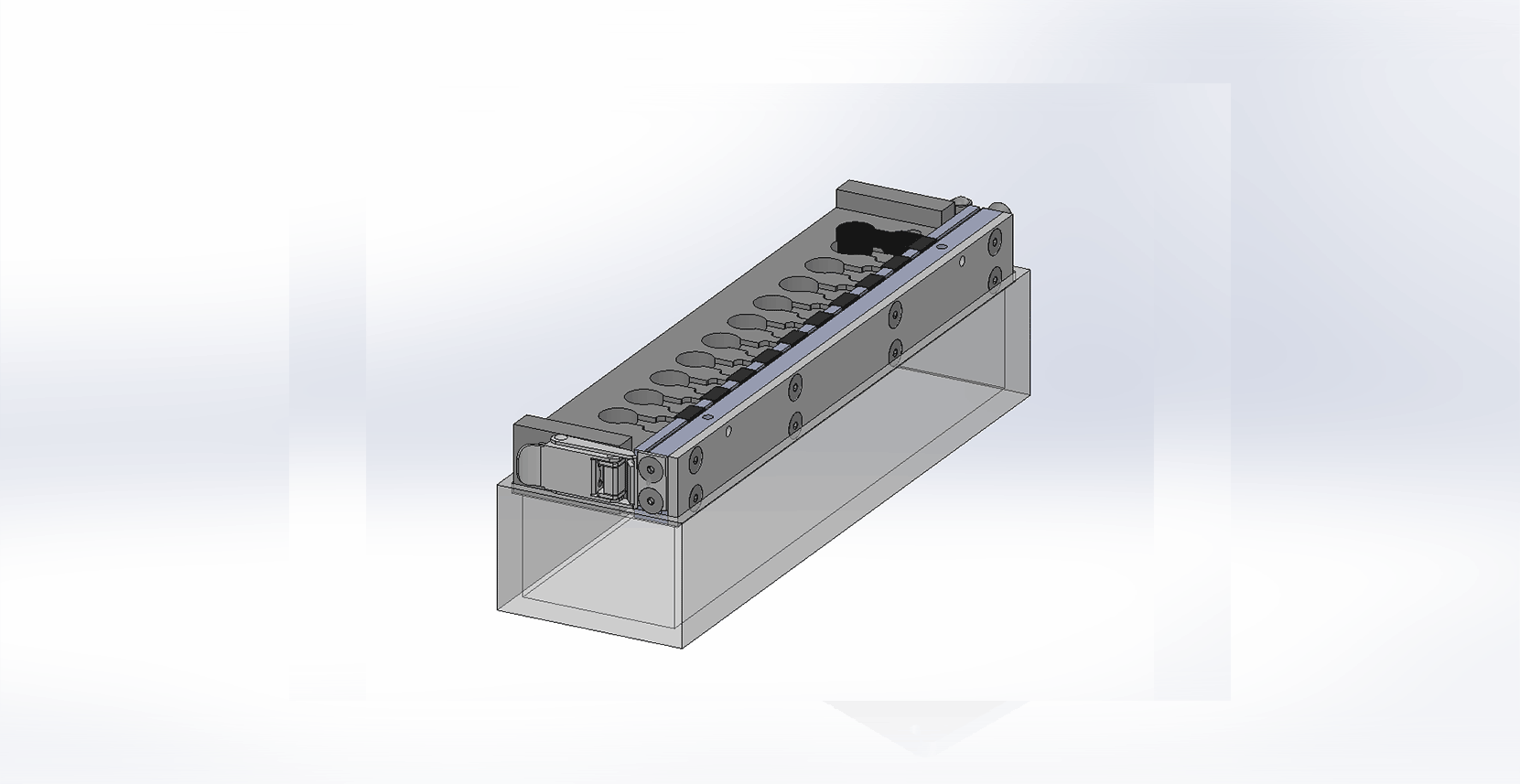

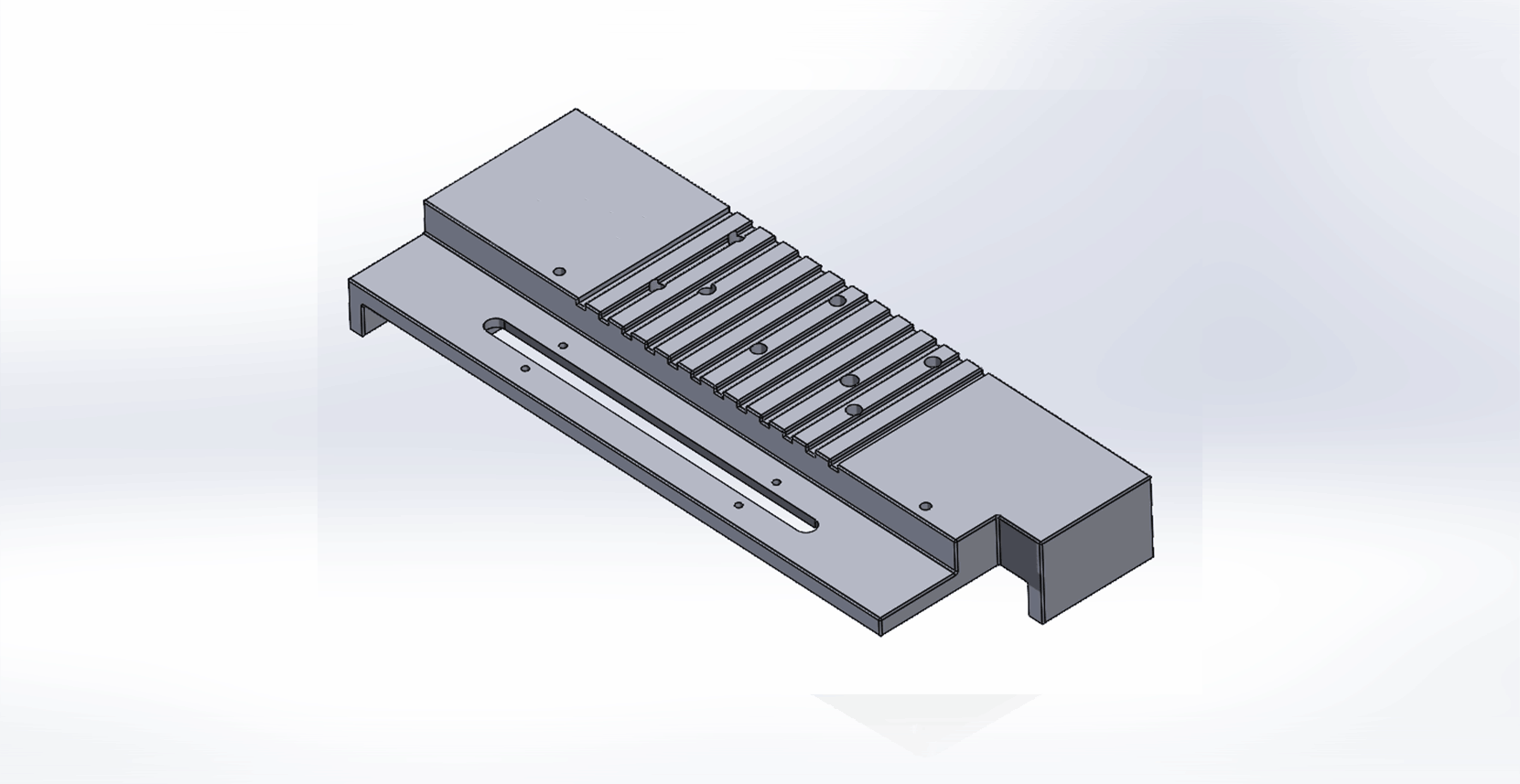

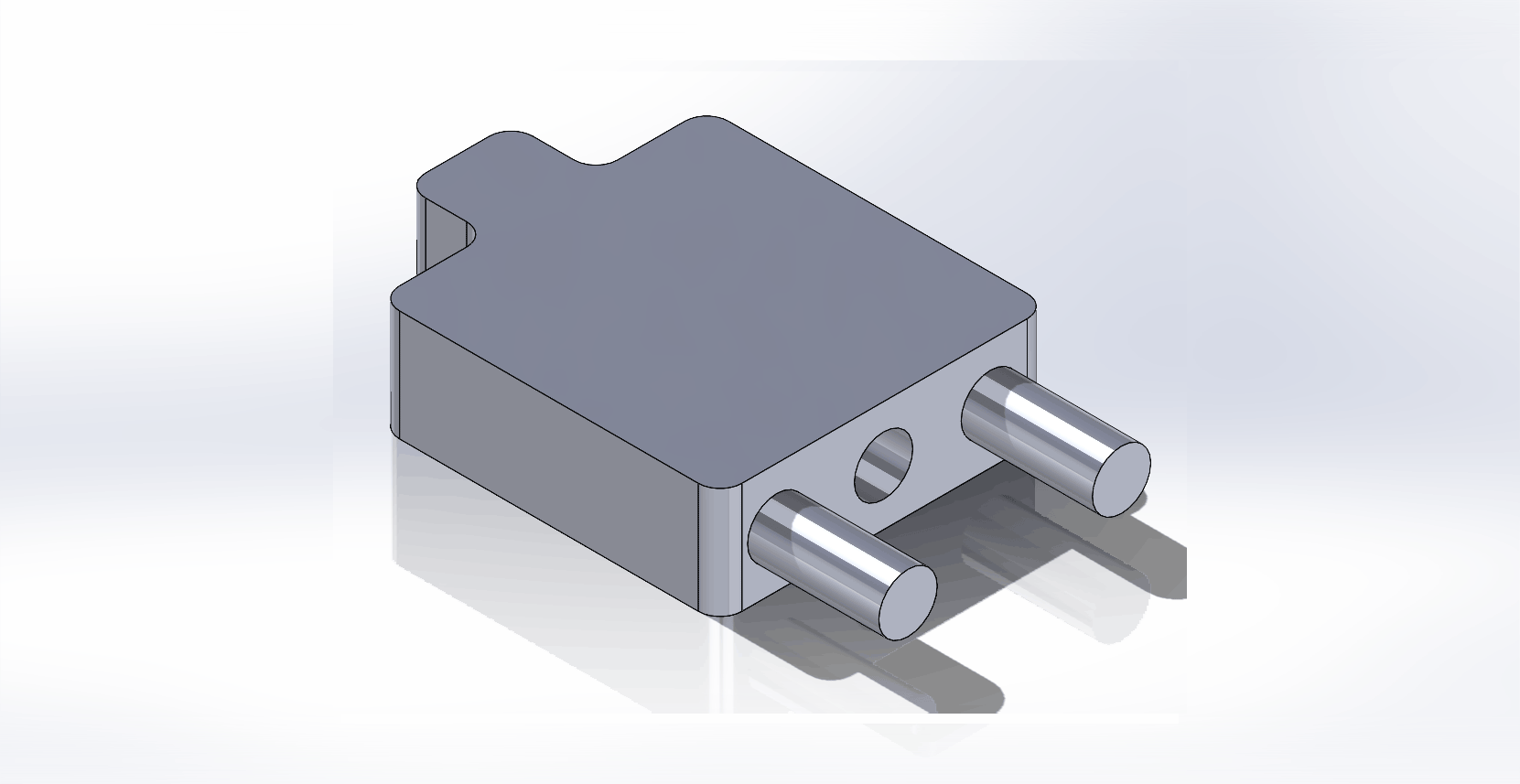

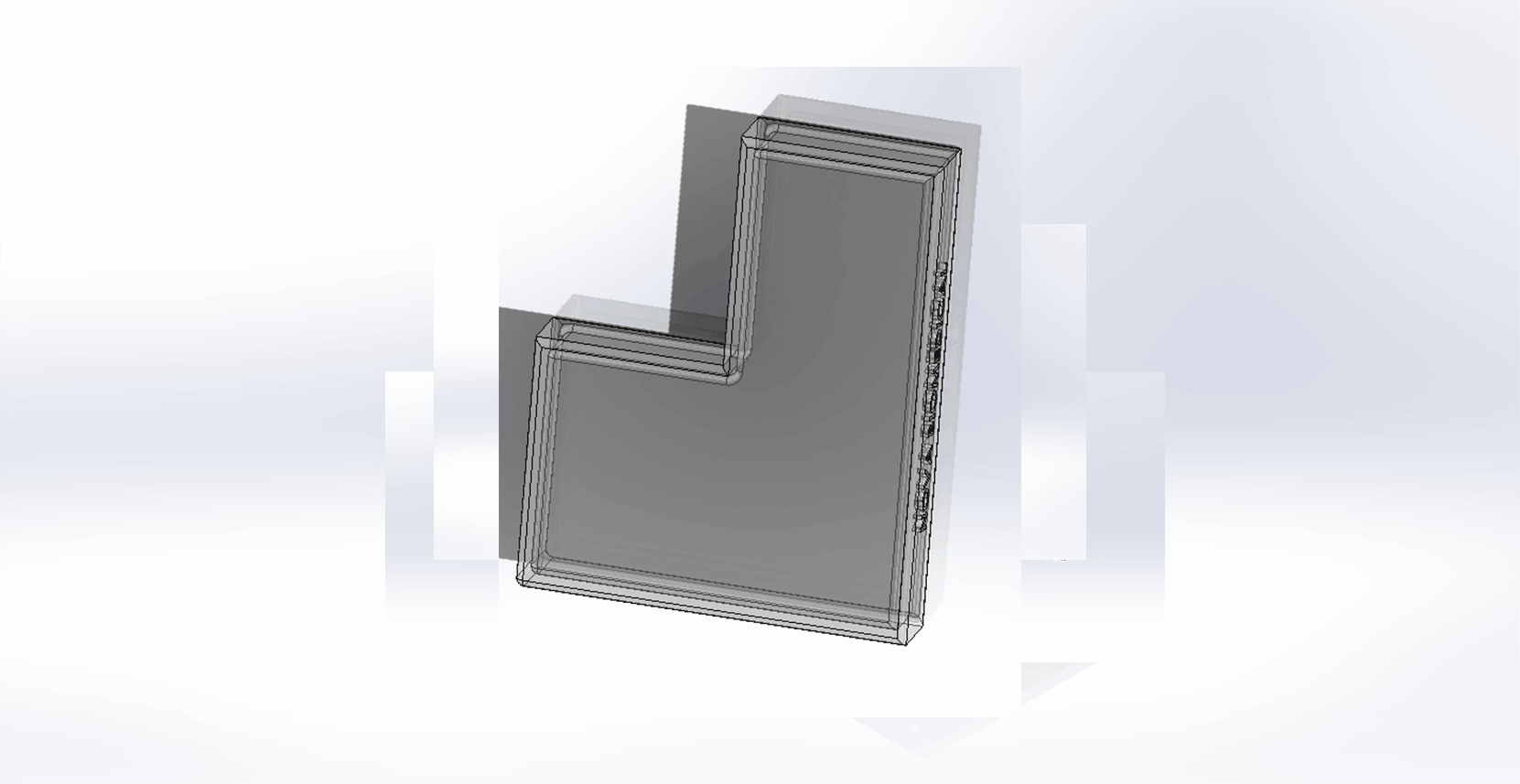

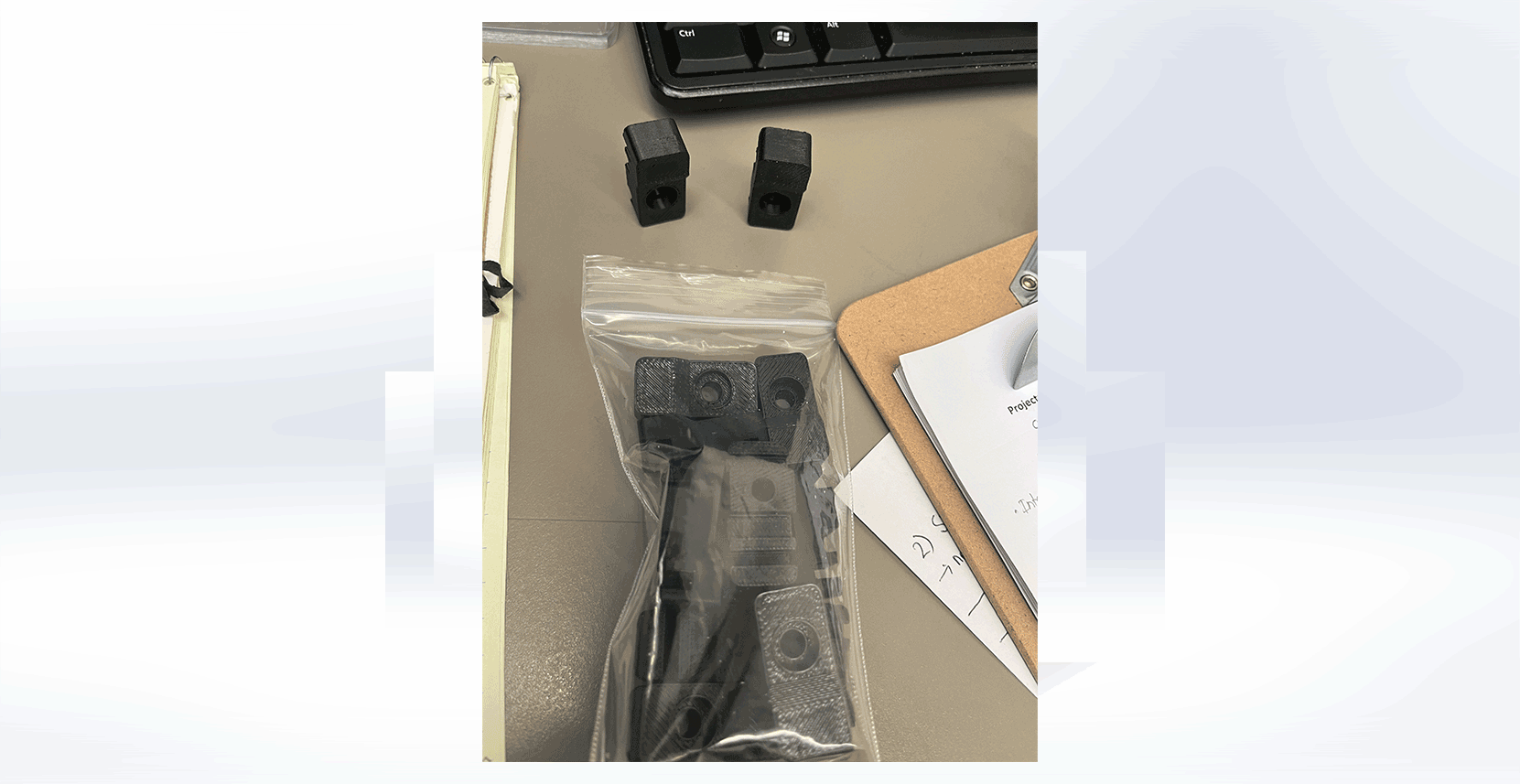

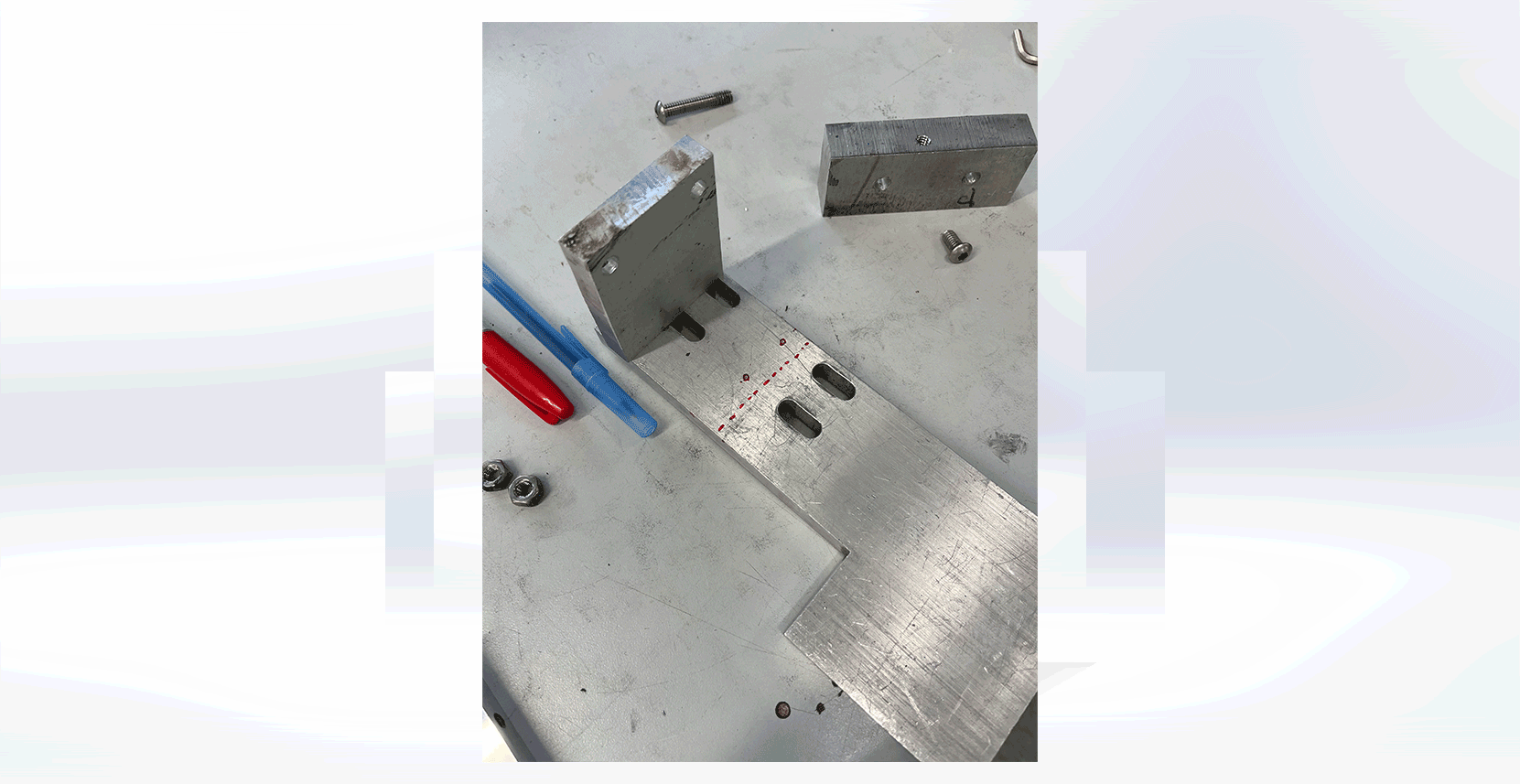

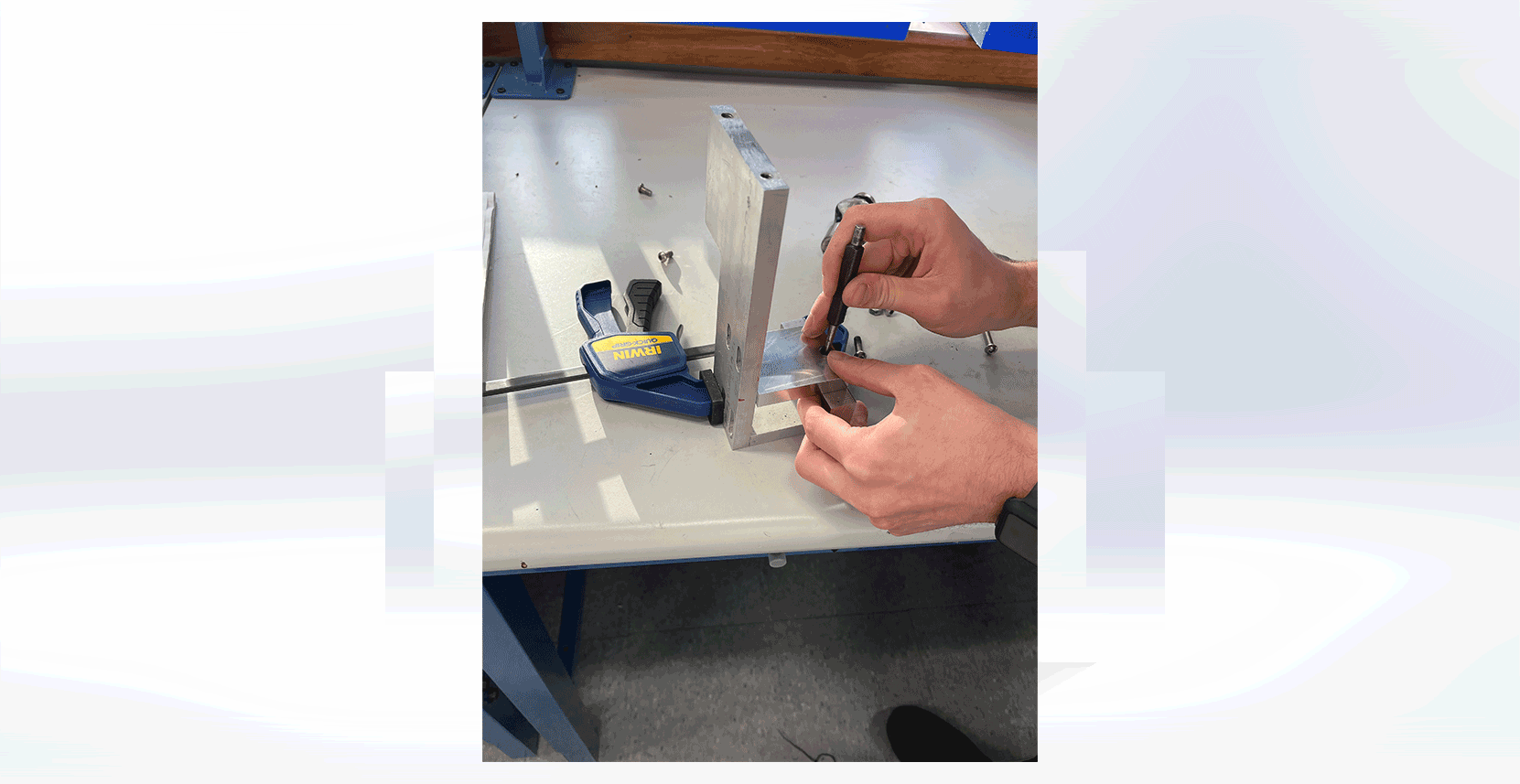

Label Press Assembly CAD

Label Machine Press Machined Parts Assembly

Intricate Design Elements

● The bottom piece features a distinct design allowing air to escape and connect from a pneumatic tube.

● On the press plate, there is a rectangular prism plate with holes that align with the adjustable rods of the label assembly.

● I reverse-engineered the existing label assembly, gathered measurements, and generated SolidWorks models.

● I then produced customized replicas to guarantee a precise fit with the adjustable rods and other screw hardware.

Excessive Force & Moment

● Current press applies too much force on Allegro packages, causing a significant moment and counter moment on plate assembly.

● I optimized screw hole placements for pneumatic bottom plate connection to the tube.

● Centered adjustable rod holes for consistent force distribution during label pressing onto packaging.

● Integrated springs to reduce press force on labels during packaging.

Label Height Variability

● Due to significant differences in height, there is variability in the positioning of labels on machines.

● This prevents the labels from reaching Allegro packages and label press.

● I modified the plate that mounts all pneumatics, adding slots for adjustability.

● This allows for flexibility in positioning the pneumatics and label press to accommodate smaller label sizes.

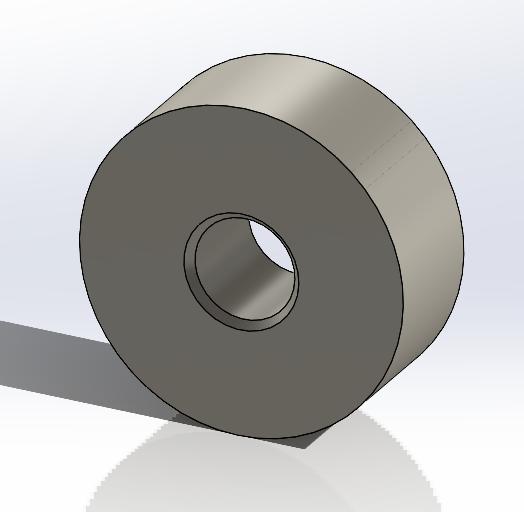

Foam Wheel Size

● Small radius of the foam wheel is insufficient for pressing labels onto smaller Allegro packages.

● After measuring the packaging, I determined the needed wheel size and inner diameter.

● I found a budget-friendly polycarbonate foam wheel on McMaster and drilled the required hole.

Tolerancing & Part Creation

● Precision is vital, given the time and cost involved in machining.

● Holes and parts need to be right first time to minimize expenses and ensure long-term stability.

● I 3D printed proof-of-concept parts in ABS and acrylic, validated designs through

label machine testing, and provided a detailed drawing to the machine shop.

● The drawing emphasized GD&T, focusing on max material condition and true position for final part production.

Result

The machined parts were successfully produced and seamlessly integrated into the label machine assembly. We provided future co-ops with instructions to inspect other components of the label machine and requested validation testing for our design across various label packaging scenarios to enhance its overall validity.

Objective:

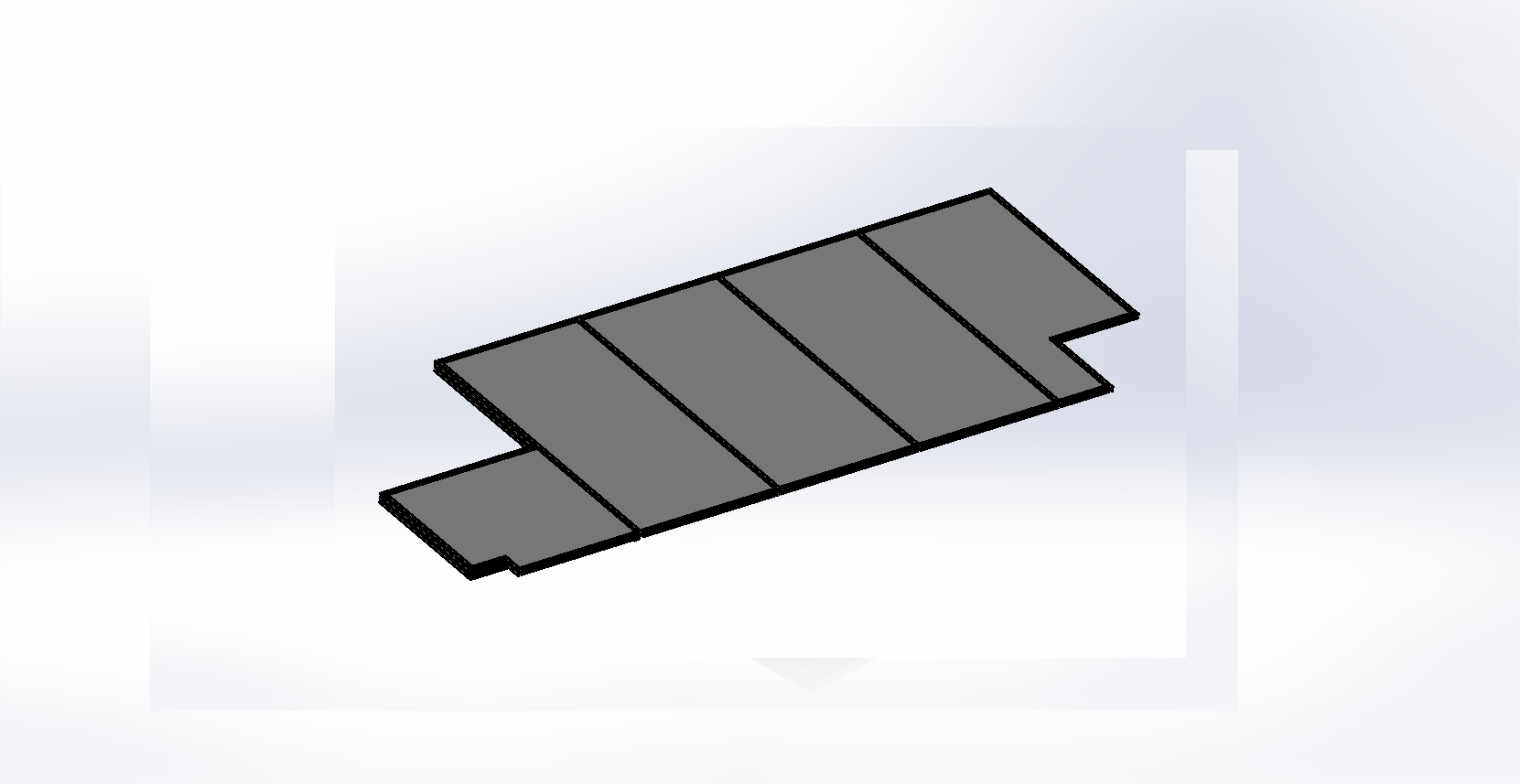

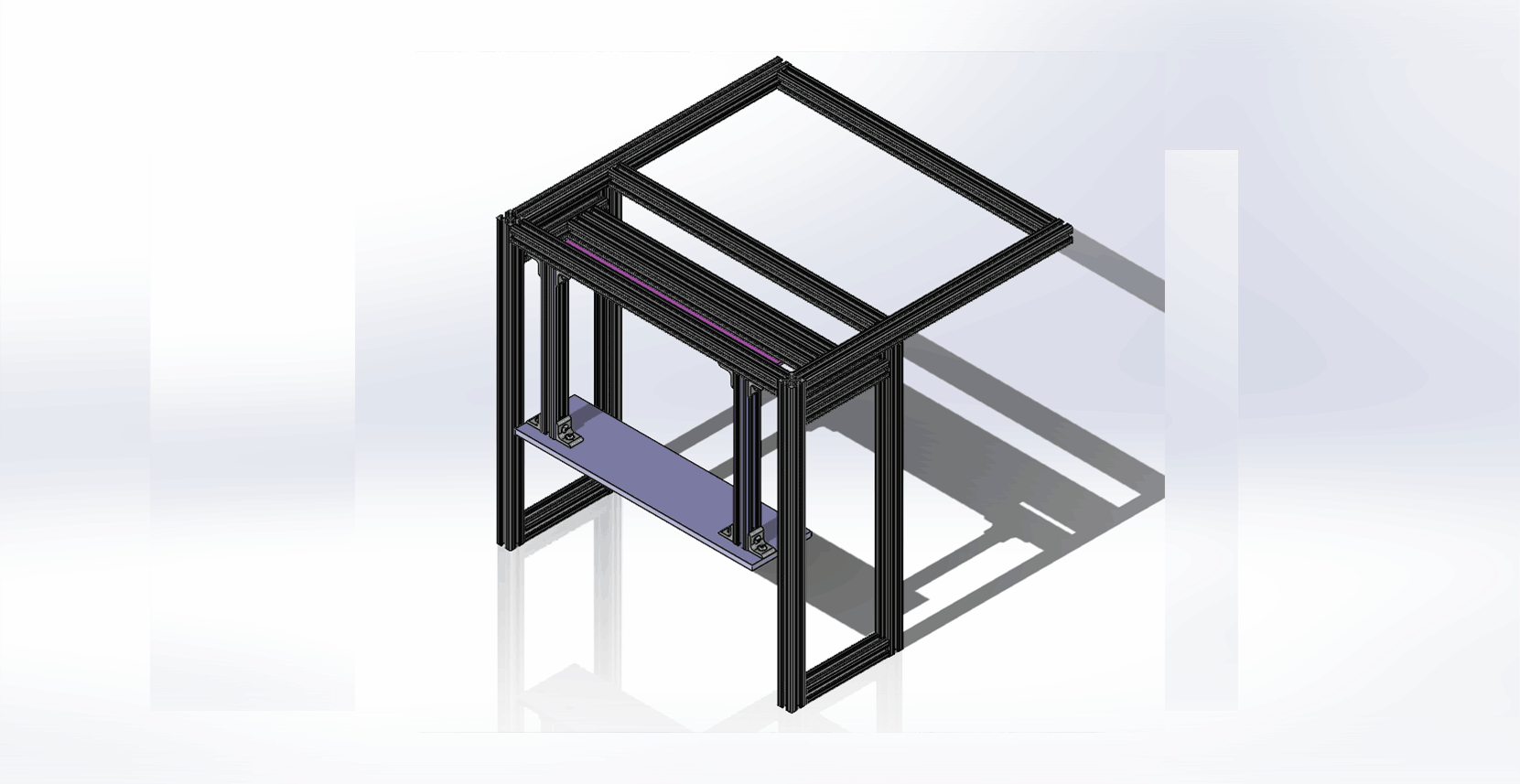

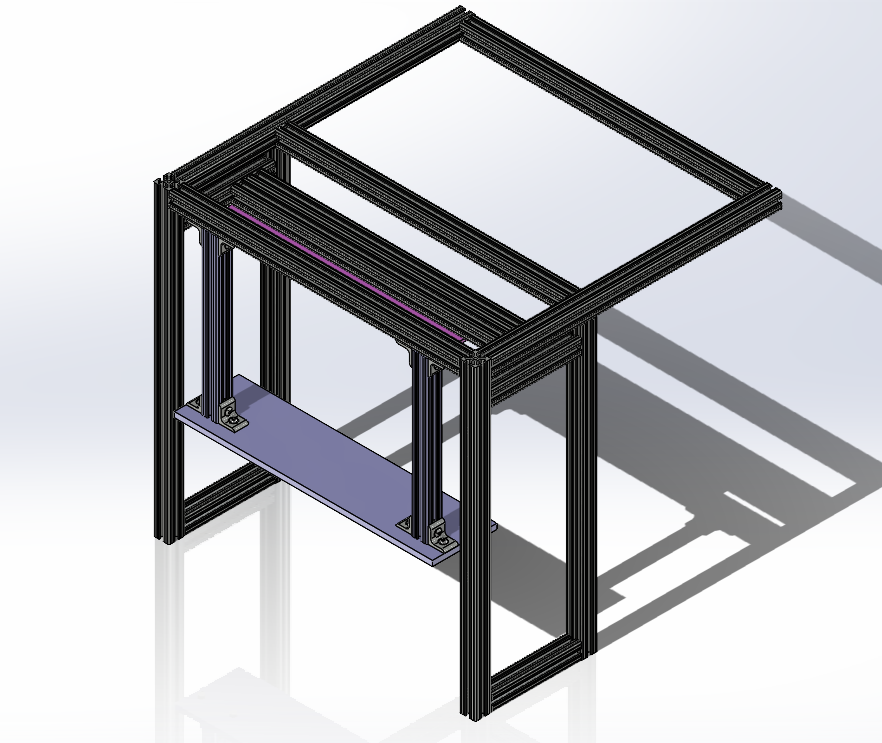

The carton machine places Nova Controls bottles in packaging. The machine is often loud and unwanted and often gets inside the machine due to no cover on top of the machine. I was tasked with creating a roof design to trap the noise in the machine and also limit dust material from entering the top of the machine.

CAD of Cartoner Roof

1010 Series T- Slots and Acrylic Panels Assembled

Applying Gaskets to T-Slots & Acrylic Panels

Structure & Support

● Placing a single large panel on top of a carton machine is impractical and not suitable for shipping.

● Utilize 1010 series 80-20 T-slots to create external support for the roof.

Machine Interferences

● The machine’s surroundings are made of 80-20 T-slots.

● Require a stable method to secure the cover with machine surroundings.

● Introduce different acrylic panels designed to slide into T-slots for added stability.

Elevation & Placement

● Existing items, such as a light indicator and monitor arm, on the top of the machine pose interference with the roof assembly.

● Address varying heights by incorporating 1020 80-20 T-slots (stacking two T-slots) and 1010 T-slots.

● This ensures that all acrylic panels are mounted on the same level when affixed to the top of the machine.

Hardware Acquisition

● Acquiring the correct hardware necessary especially when assembling the panels to T-slots.

● Collaborated with NEFF application engineers to ensure comprehensive hardware acquisition.

● T-nuts, gaskets, brackets, and fasteners were provided for assembly.

Result

I led a team of engineers in assembling the roof by arranging 80-20 pieces, securing frames with t-nuts and fasteners, sliding panels in place with gaskets, and affixing the roof to the machine using surface brackets. This achieved a significant reduction in machine noise and minimized dust entry, just as we hoped.

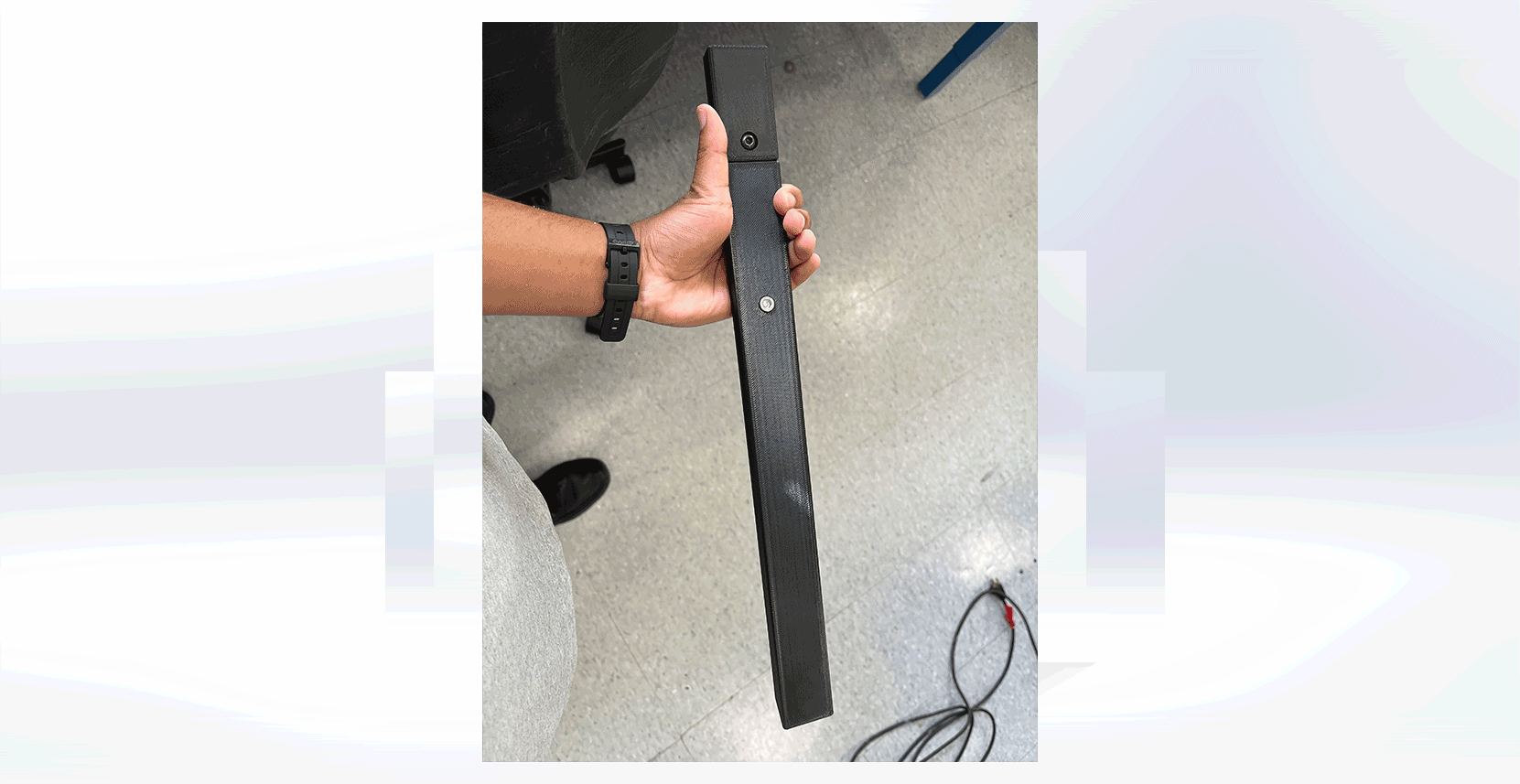

Objective:

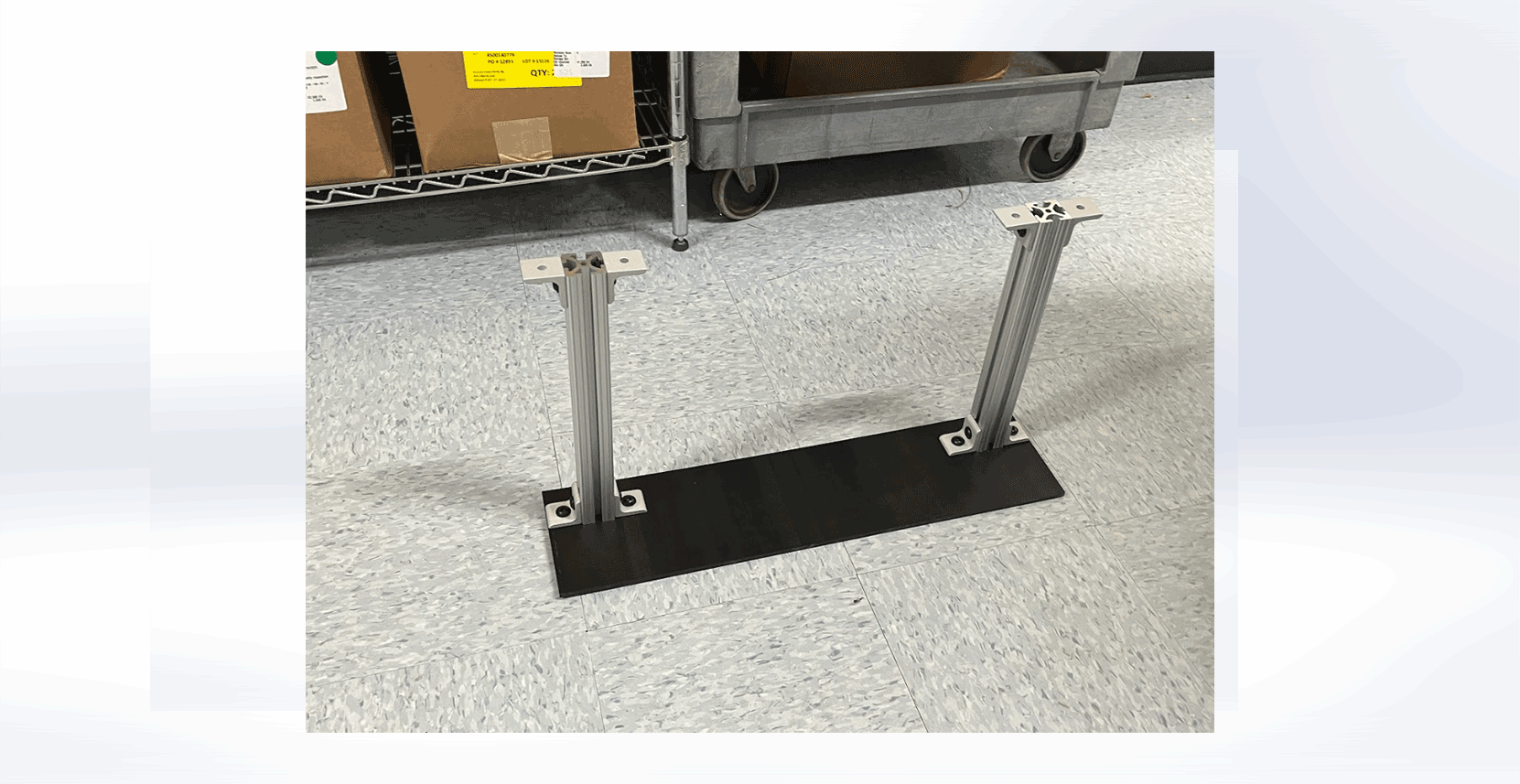

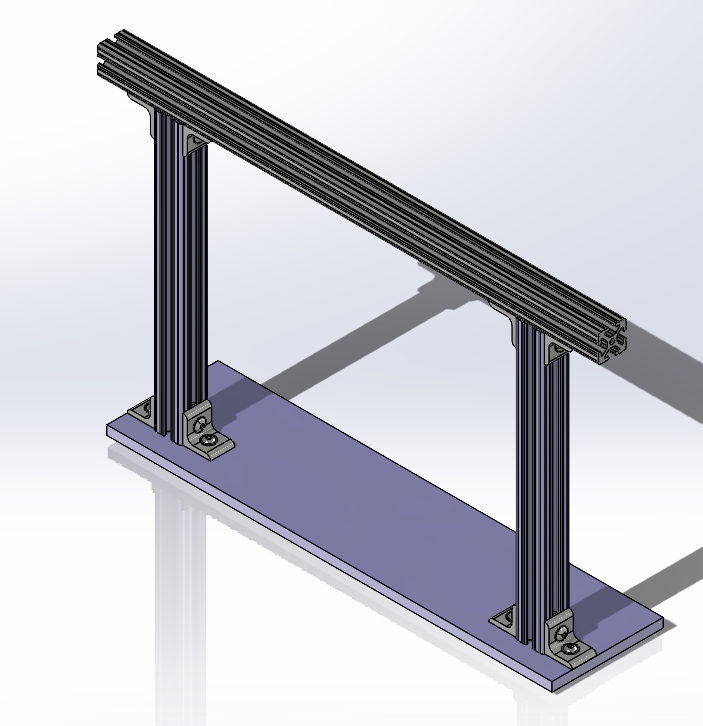

The cartoner machine would have leaflets that were added to several Nova packages. However, some leaflets would fall off the machine instead of the conveyor belt. My task was to create a design that would catch these leaflets on top of a conveyor belt. This design also had to be under the budget of $200.

Mounting Considerations

● Deflector cannot be placed on a moving conveyor belt surface.

● How will it be securely mounted without hindering the belt's movement?

● Identify pre-existing 80-20 1015 T-slots functioning as a cover for carton machines.

● Use this framework on the machine for streamlined mounting of the deflector’s support rods.

Potential Interferences

● Deflector should not obstruct leaflets, and its support structures cannot interfere with moving parts or wiring.

● Conducted a detailed model of the surrounding 80-20 and other machine parts to evaluate available space for the deflector.

● Installed two 1015 vertical 80-20 T-slots onto existing 80-20, connecting them with a plate to serve as the leaflet catcher.

Assembly & Hardware

● What is the optimal assembly method for integrating deflector into the machine?

● How can we ensure that it maintains rigidity and proper support?

● Install four corner brackets on each of the two T-slots, two connecting to the existing top 80-20 frames and two to the base plate.

● The base plate features drilled and tapped holes I made for secure bracket attachment.

Budget Friendly Approach

● With a project budget below $200, how can we purchase parts while minimizing the need for machining/cutting modifications of parts?

● Secured materials from McMaster using corner brackets (came with T-nuts and screws), 24” x 6” x ¼” Black Delrin Acetal Resin Bar, two 1.5 ft long 1015 T-slots

● The Resin Bar only required hole drilling since I made the base plate in the design same dimensions as this bar.

● T-slots were trimmed from to 15 inches in machine shop. Total project cost less than $140.

Result

I assembled parts by drilling and tapping holes on the plate, cutting sections of 80-20 T-slots, and mounting brackets onto the plate and existing T-slot. I also adjusted wiring for optimal placement for the T-slots. The deflector proved effective; however, considering an enhancement, I recommended exploring adjustable rods to allow flexible vertical movement of the plate. Documented this design concept for new co-ops to further investigate and improve upon my existing design.

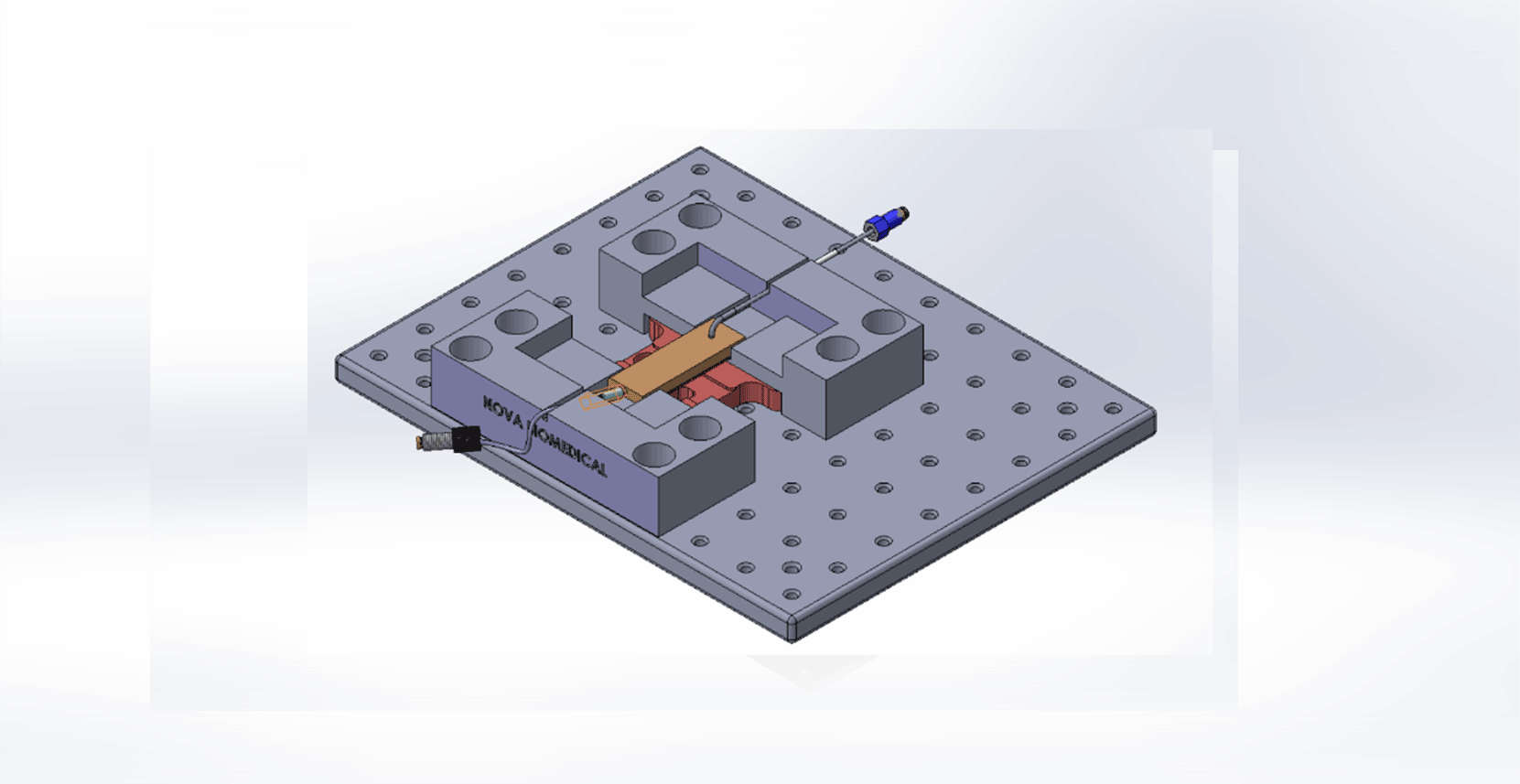

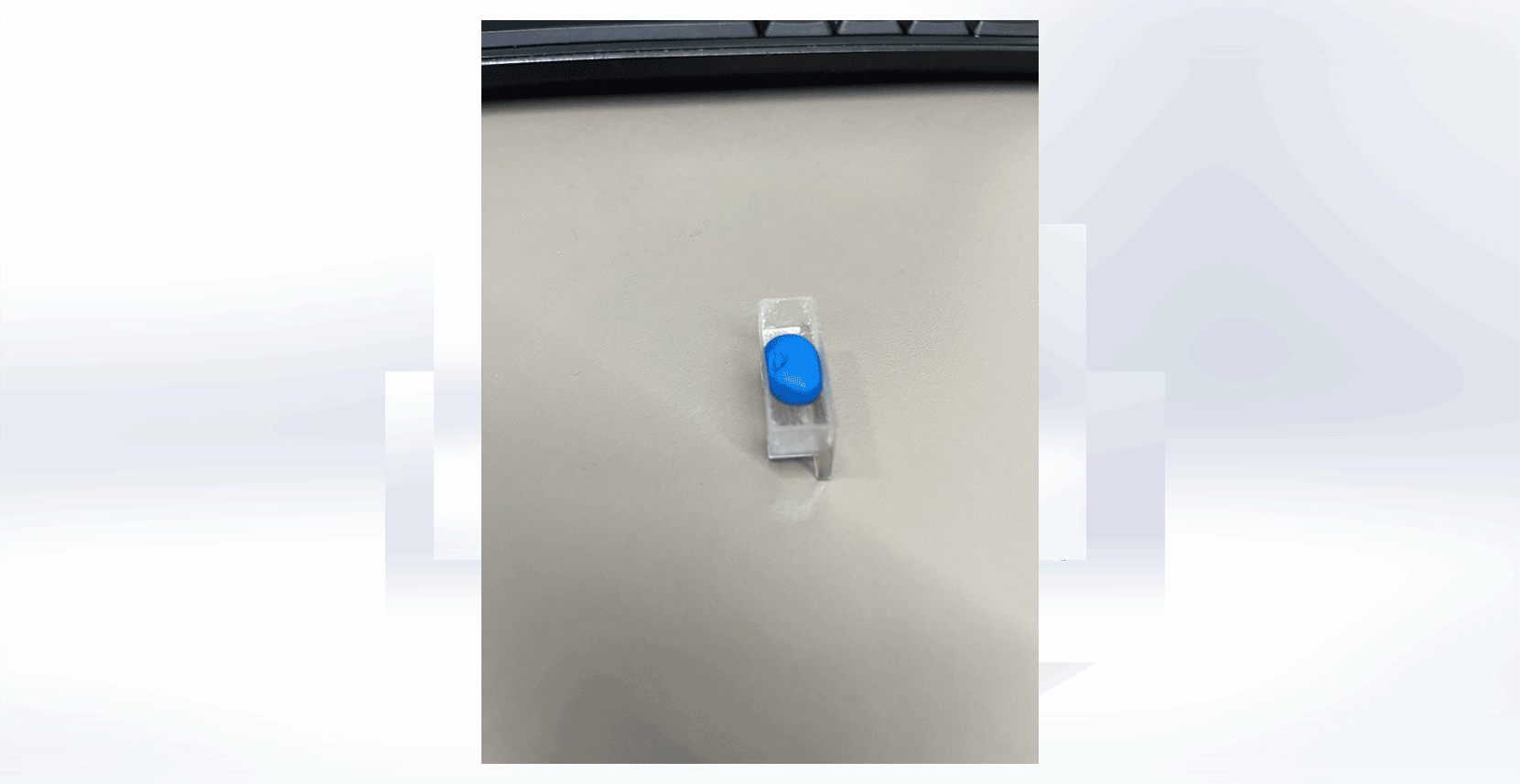

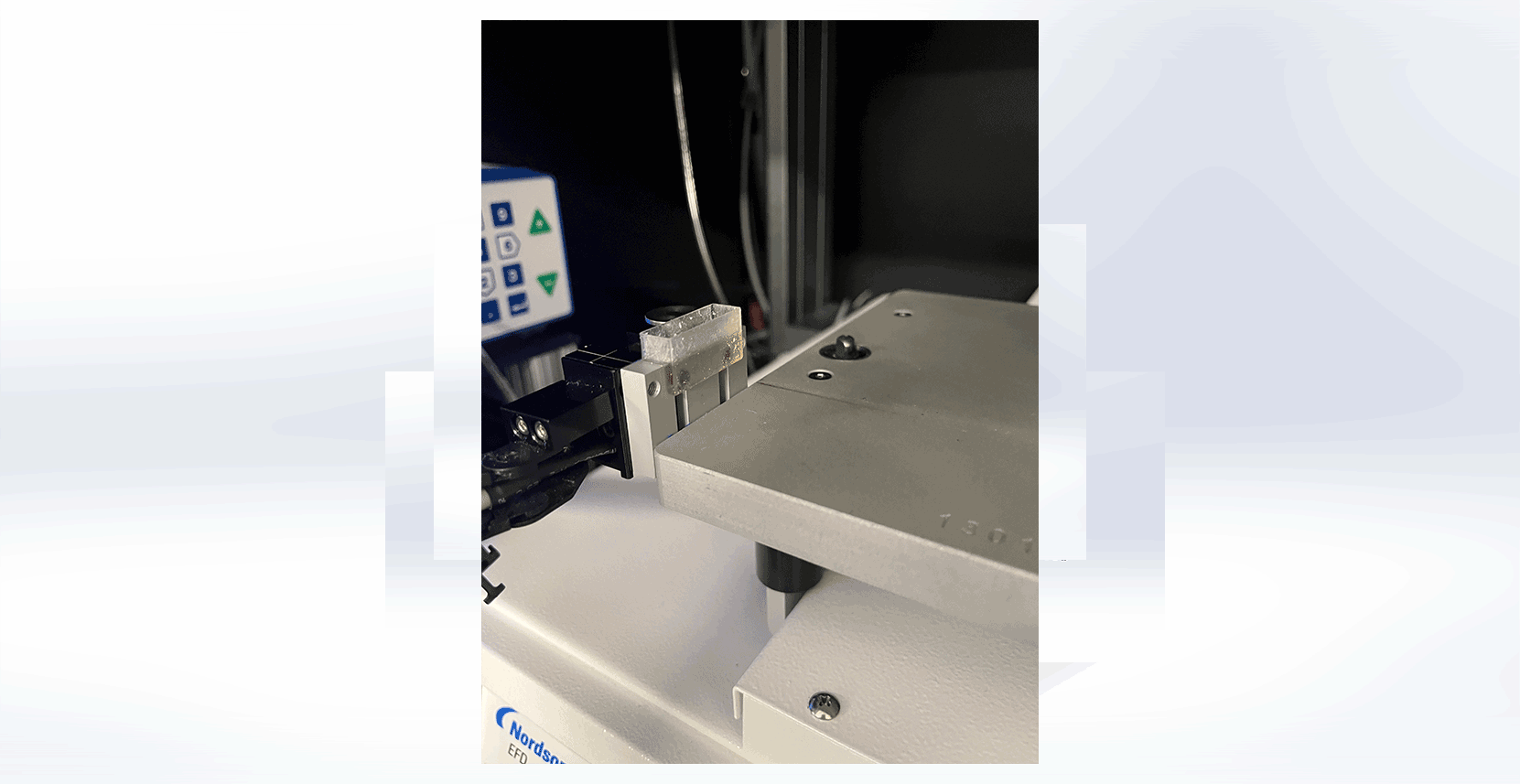

Objective:

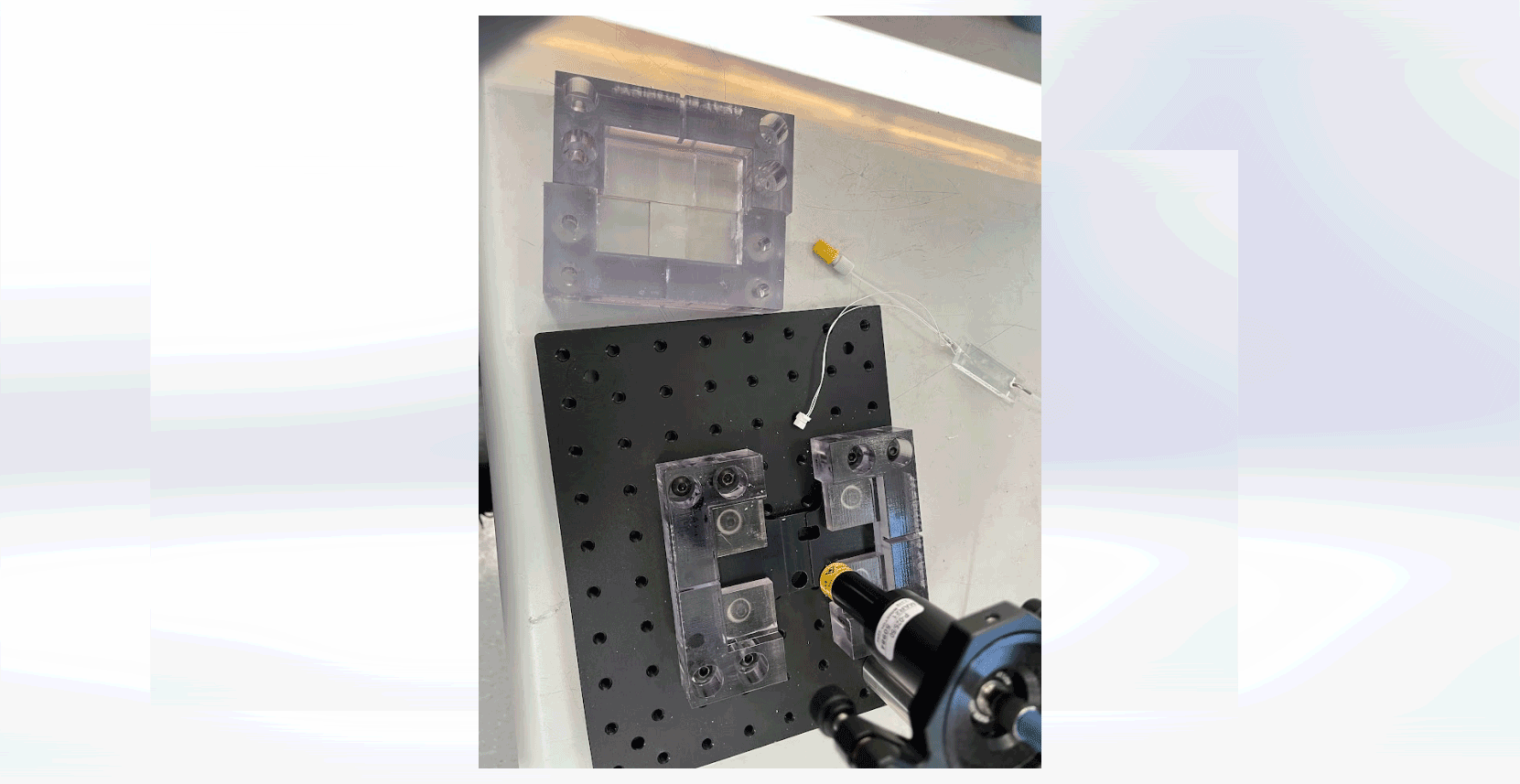

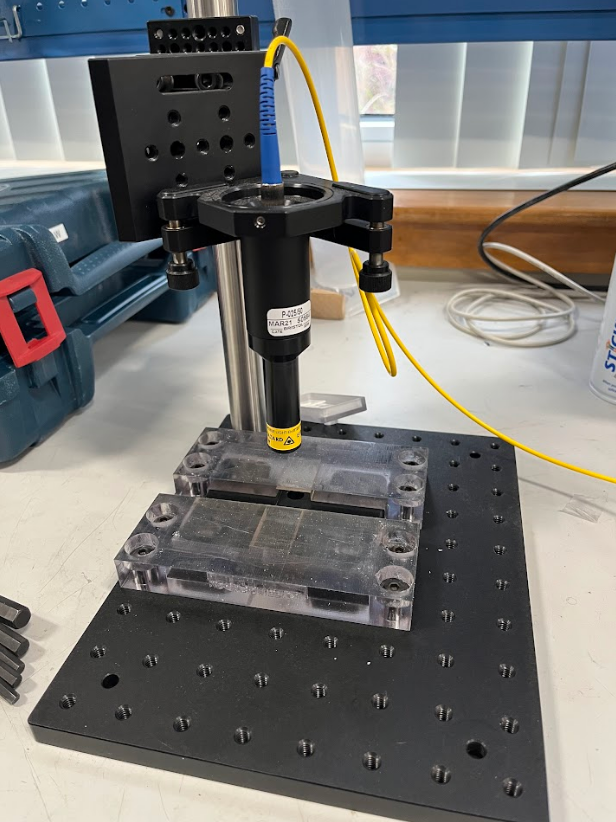

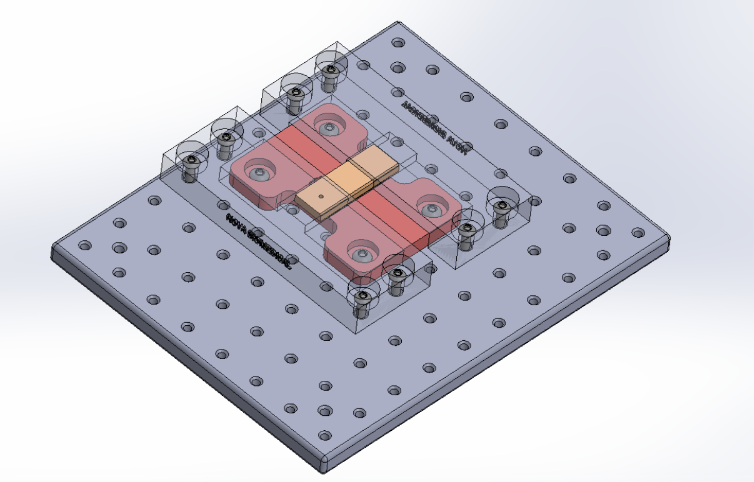

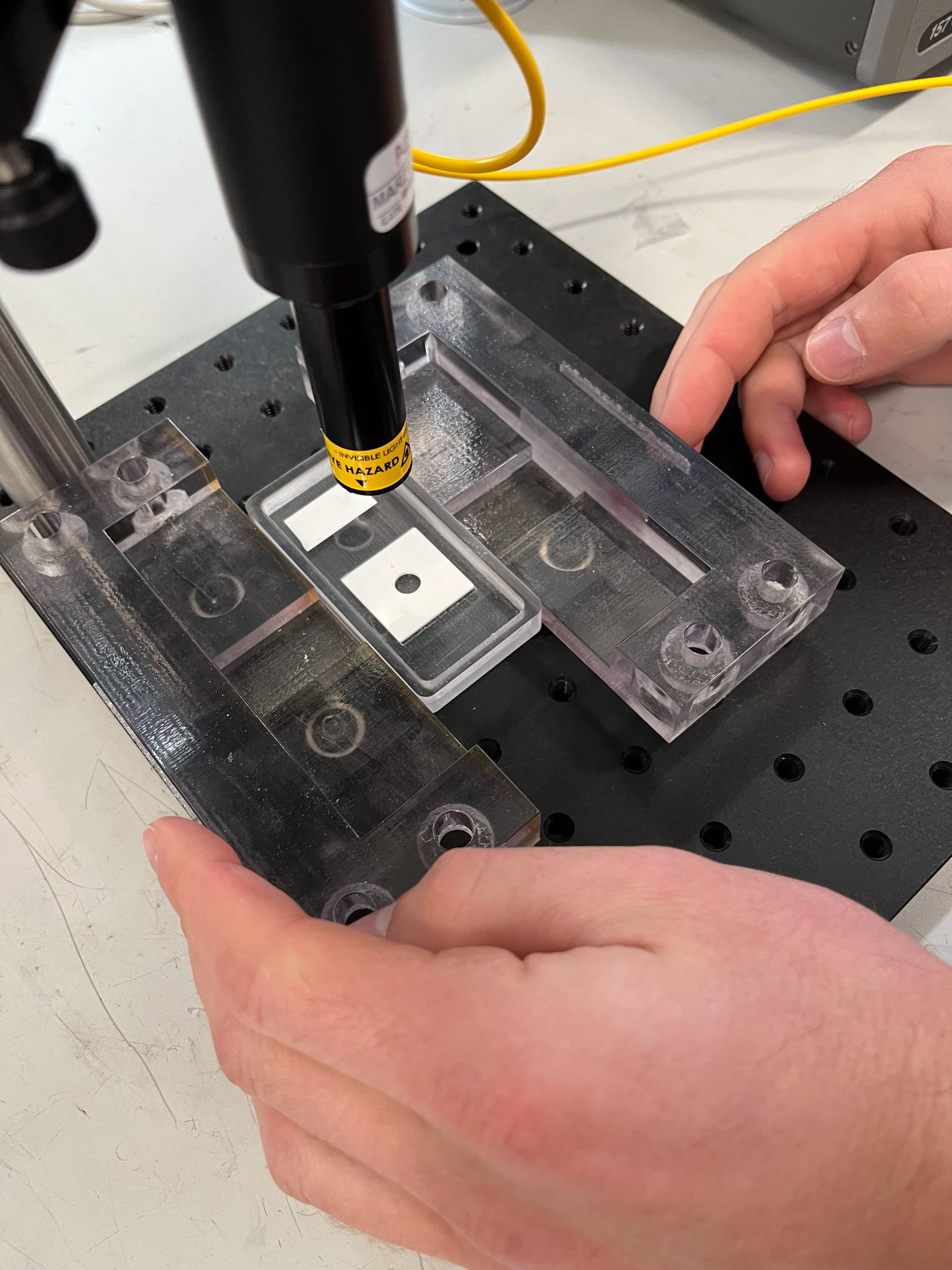

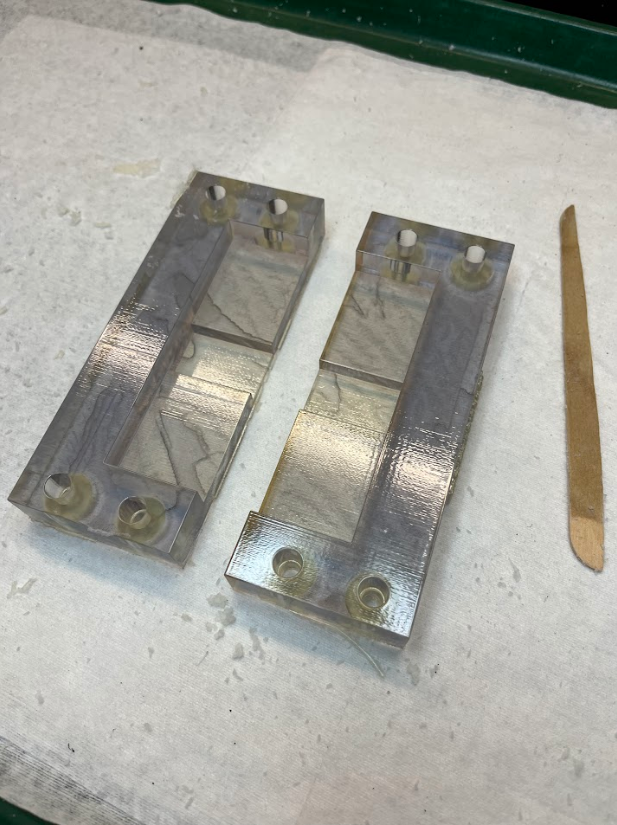

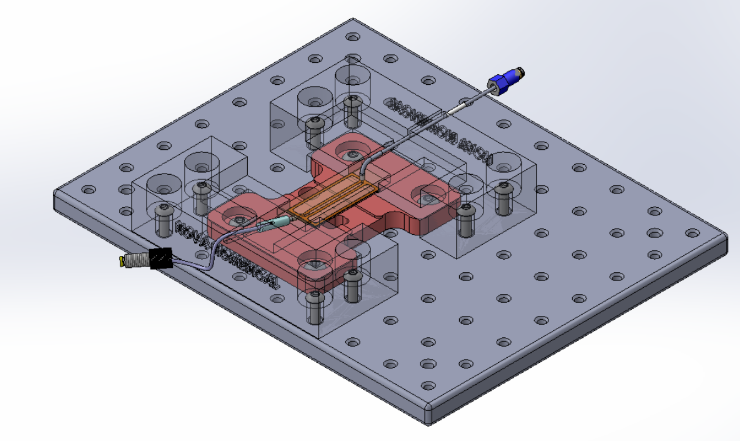

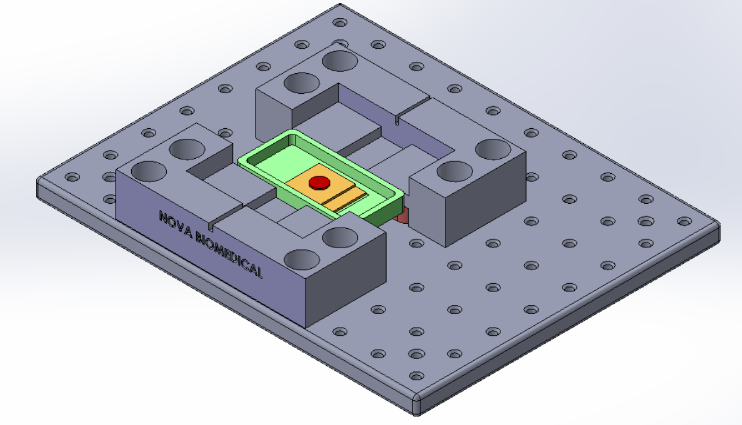

Enhance the stability of cuvettes used in the sensors department to ensure accurate identification of optical path length and reflected signals for part creation. The objective is to design and implement a secure guard on the cuvette placement surface, addressing the challenge of unwanted movement during testing with the laser and Bristol Instruments Opti-cal software.

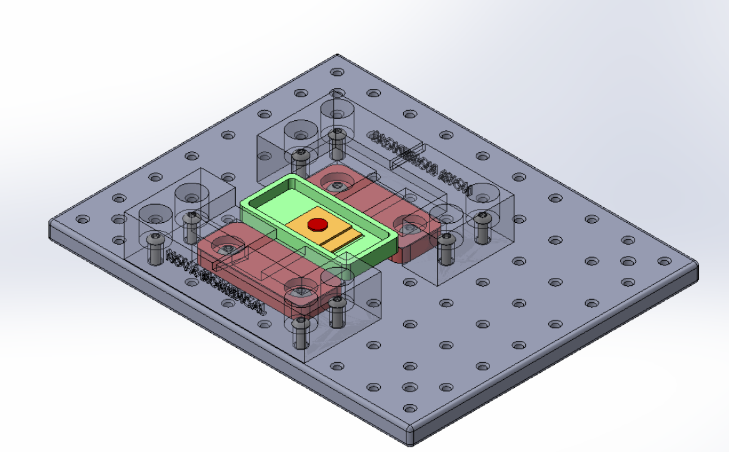

Cuvette CAD Assembly

Testing Acrylic Guards with Laser

Spatial Constraints & Acrylic Guard Integration

● Navigate limited space for cuvette placement

● Ensure acrylic guards do not impede cuvette positioning.

● Incorporated surface measurements of the cuvette placement area into assembly for precise compatibility.

Integration with Cuvette Tubes

● Potential impact on maintaining straight positioning for the cuvette given there are tubes on the left and right side.

● Modeled acrylic left and right guard to accommodate tubes seamlessly.

● Prevents wire entanglement.

Missing Device Components

● Missing model for base plate.

● Base plate crucial for bolt hole placement for the acrylic guards.

● Measured and modeled the base plate including tapped holes. ● Lays foundation for other elements in assembly.

Versatility in Design

● Devise a solution for another part occupying the same location as the cuvette.

● Acrylic guards should be versatile enough to accommodate both components effectively.

● Utilized width mates to place cuvette and other components in the assembly.

● Demonstrating compatibility by suppressing one part in the model while presenting the other to ensure a proper fit.

Result

Following iterations with various guard designs, the acrylic guards, featuring well-placed counterbores, seamlessly integrated into the cuvette assembly. The laser pointer accurately retrieved data from the cuvette, as demonstrated in the Bristols Instruments Opti-cal graph, ensuring stability during testing. Additionally, I generated a comprehensive drawing detailing the various components of the assembly.

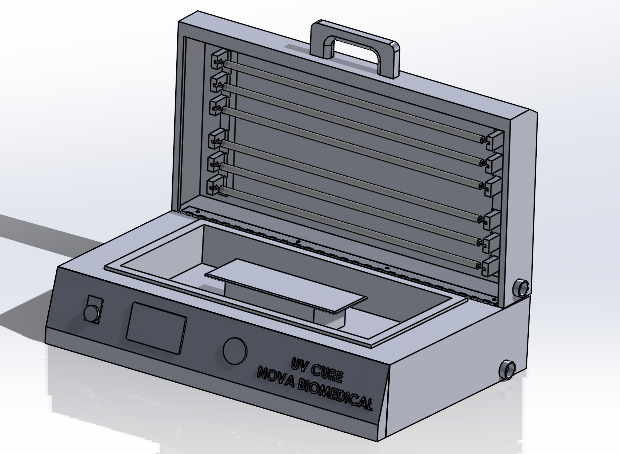

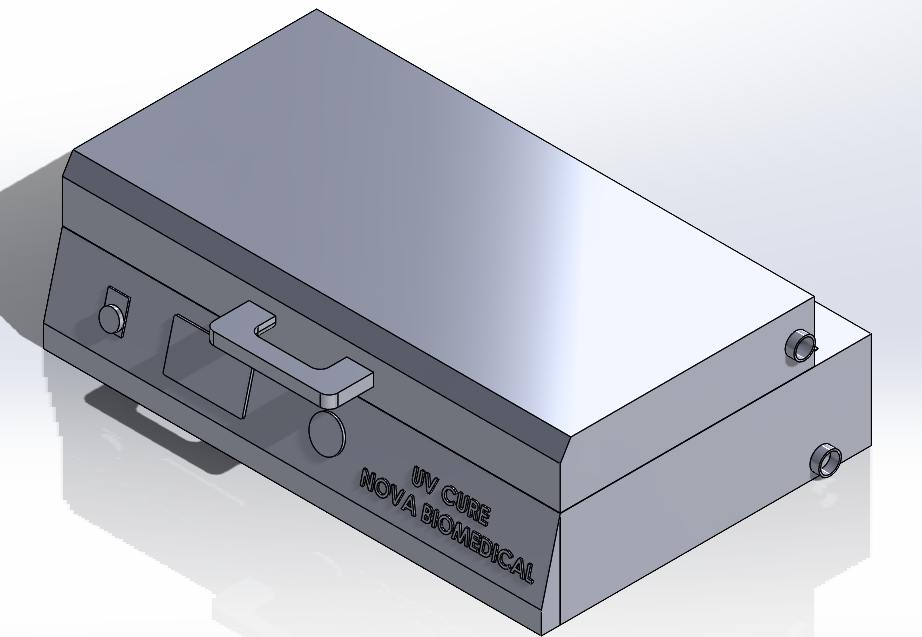

Objective:

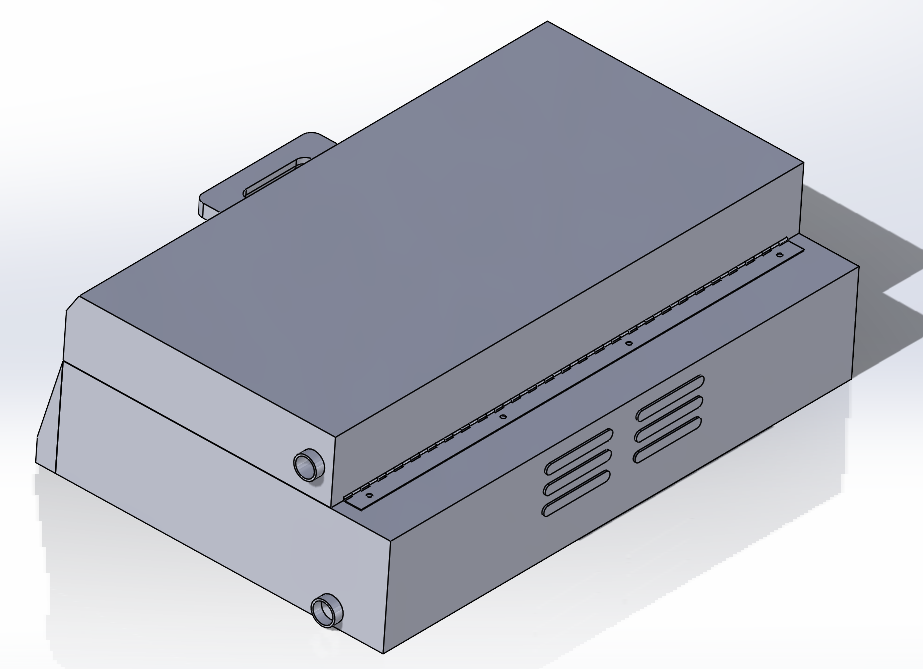

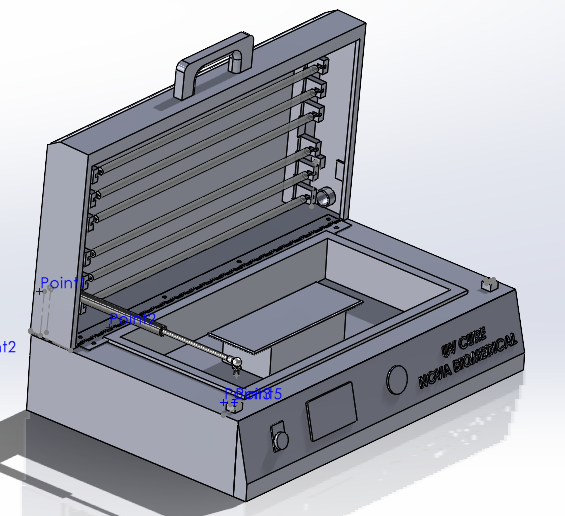

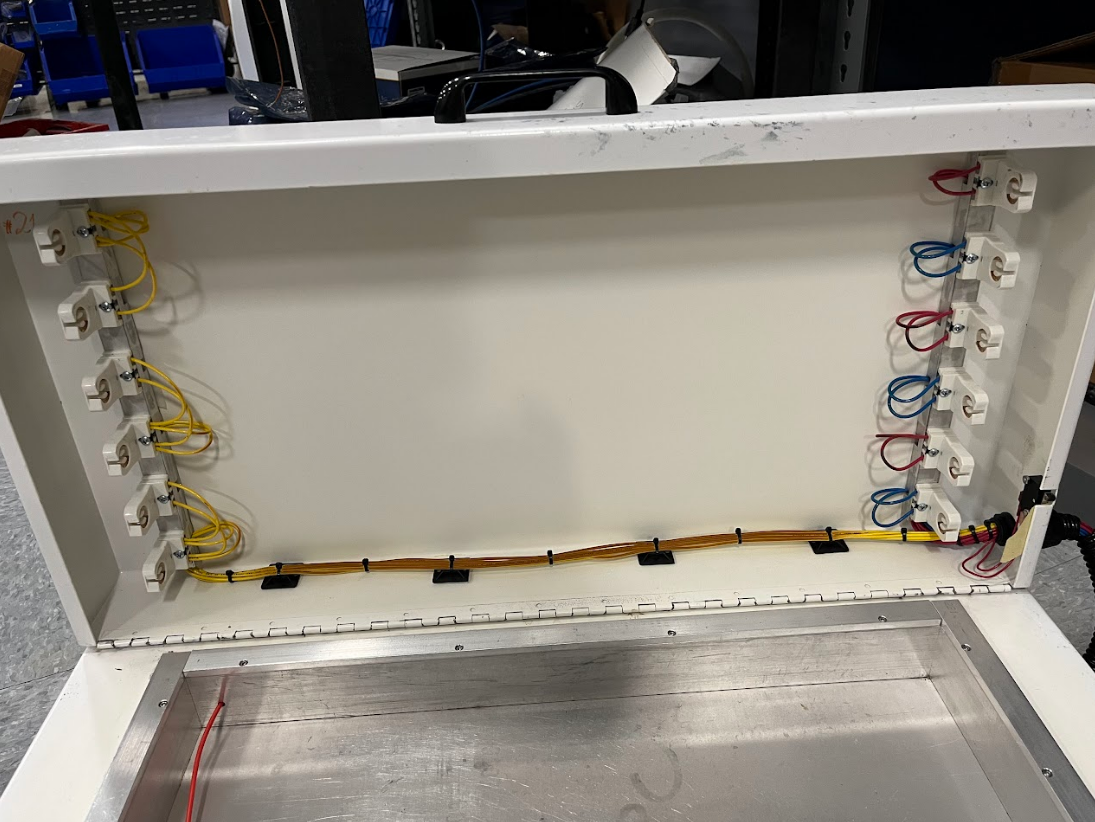

Nova Biomedical's planar department frequently employs UV curing devices. However, a significant problem arises with these devices as many individuals frequently sustain injuries while attempting to open the latches. Additionally, the cure lids are heavy, and the incorporation of lid assistance is deemed necessary. My assigned task involved modeling the UV curing devices used at Nova Biomedical and implementing new latches and gas springs to enhance the ergonomic friendliness of the devices.

Economic Evaluation of Two Cure Types

● There are two variants of the UV Cure device.

● Emphasis should be placed on prioritizing the one that is both extensively used.

● Developed two UV Cure models - one with and one without a lip.

● Despite initial interest in the lip-less model, it was deemed impractical due to high usage of other UV model.

● Model with lip necessitated stronger springs due to heavier lid.

Cure Modeling and Optimization

● The UV Cure presents a complex geometric challenge.

● Presence of a lip on the lid and shell structure.

● Measured the UV cure from different angles.

● Faced lag issues with the old model’s multiple assembly files.

● Streamlined new UV cure model by consolidating top lid components as one part file (same for bottom lid), reducing the need for numerous mates.

Determining Hinge Placement and Movement

● Hinges are typically situated inside the device but there are other UV Cures that have

them located externally impacting placement of gas springs.

● Fishbone diagram created to illustrate effects of hinges on assembly process

● Old UV Cure model I made custom hinges, but modifications needed multiple times due to part interferences.

● Explored hinge styles, found a suitable match on McMaster for new UV cure.

● New extended hinges allow for flexible open and closing motion for both bottom and top lids.

Implementing Efficient Latch Mechanisms

● Efforts are directed towards ensuring that the latches facilitate easy unlocking and locking during opening and closing lid.

● Initially used snap latches, but after realizing ergonomic issues during testing, consulted

with application engineers from SouthCo.

● Recommended rotary latches with mounting plates for improved functionality.

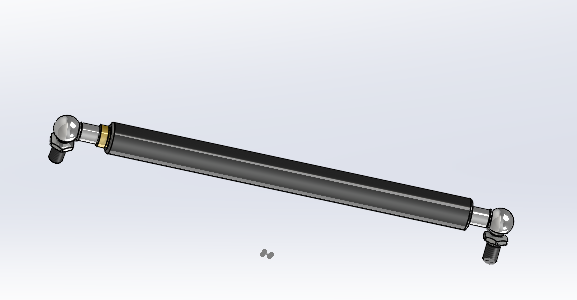

Integrating Gas Springs for Enhanced Functionality

● Navigating intricacies of gas springs.

● Learning curve for both myself and the engineering team.

● Researched push-up and flip-over designs, gas spring positioning, and handling forces.

● Collaborated with Camloc application engineers via Teams and email.

● Helped create force analysis diagram, determining optimal gas spring locations and

types.

Lip and Wiring Interference

● Some UV Cure top lids lack a lip while 70% of others have one.

● Certain lids with lips also house a considerable amount of wiring.

● Ensure clearance locations in the model where the top lid contacts the bottom base

during closure.

● Accounted for wiring to prevent interference with gas springs.

Result

Modeled gas springs and latches for the old UV cure. Developed a new UV cure model with gas springs and facilitated the purchase of the necessary components. Provided comprehensive research for future co-ops on gas spring assembly, including the placement of mounting plates for sheet metal devices, and recommended latch types. While I didn't handle the project's assembly, I established the research foundation for my team's engineers. Additionally, I created a drawing for a new UV cure model without springs.

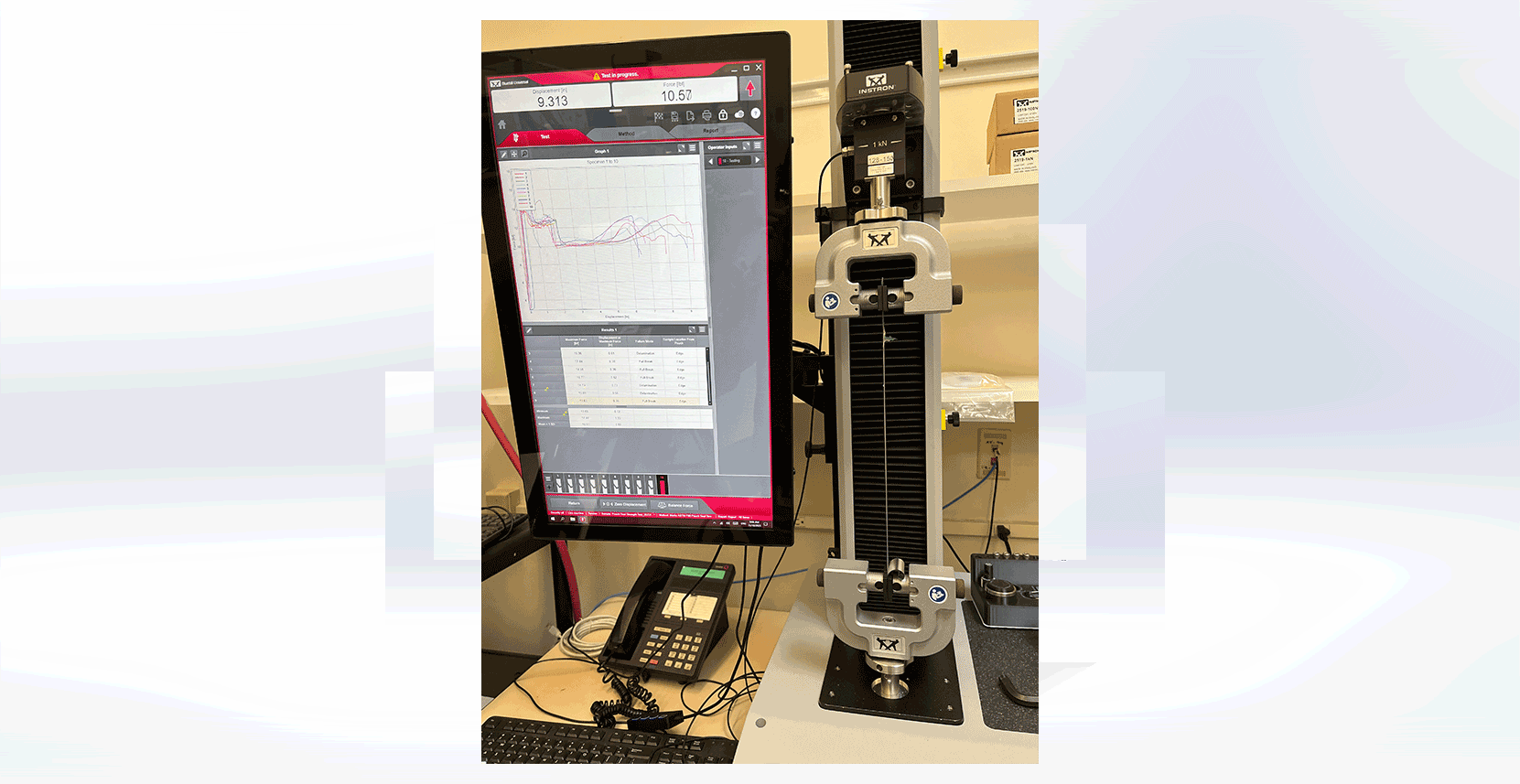

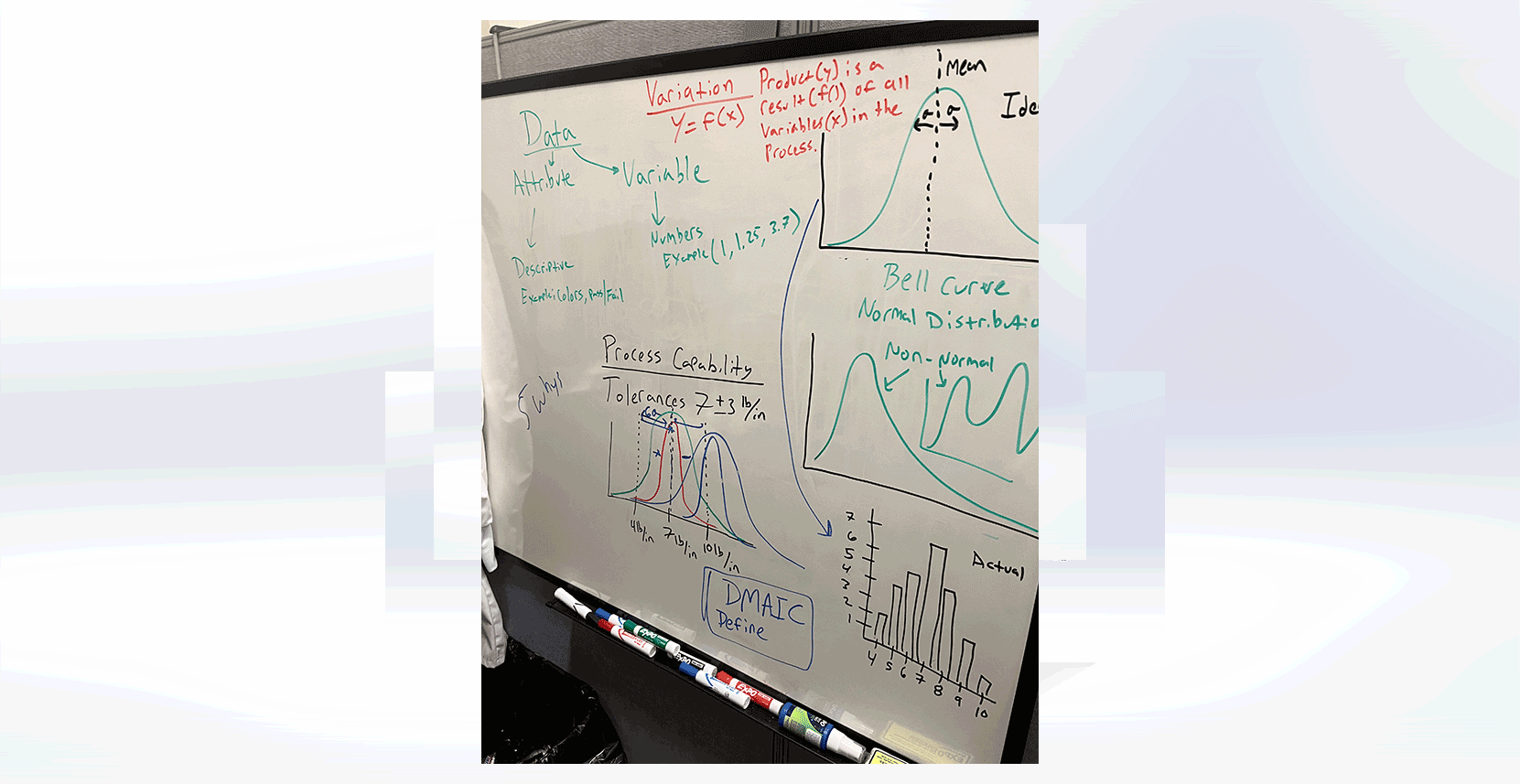

At Nova, guaranteeing the strength of pouch seals containing fluids is pivotal. Collaborating with

my manufacturing co-op team, we systematically conducted tensile testing on batches, each

comprising precisely 30 samples, using the Instron machine. Post-testing, stress-strain curves

were meticulously plotted, and a thorough data analysis in Minitab ensued, applying DMAIC

methodology. This approach ensured a robust assessment of the normal distribution of pouch

data and verified the acceptability of process capability and tolerance, reinforcing the

commitment to quality assurance in Nova's packaging.

Instron Machine Testing Seal

Seal Testing Stats Review

Some of Pouches I sampled

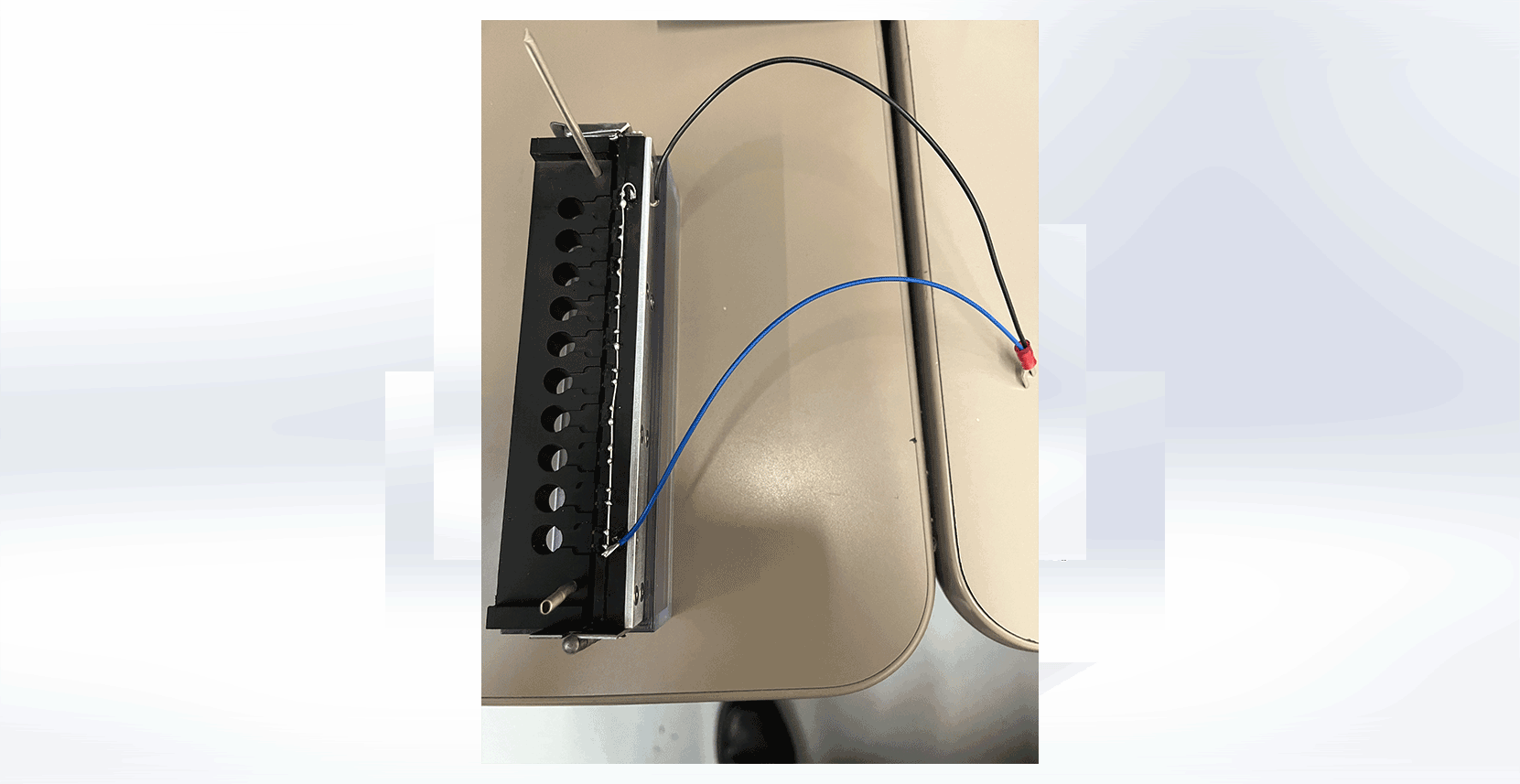

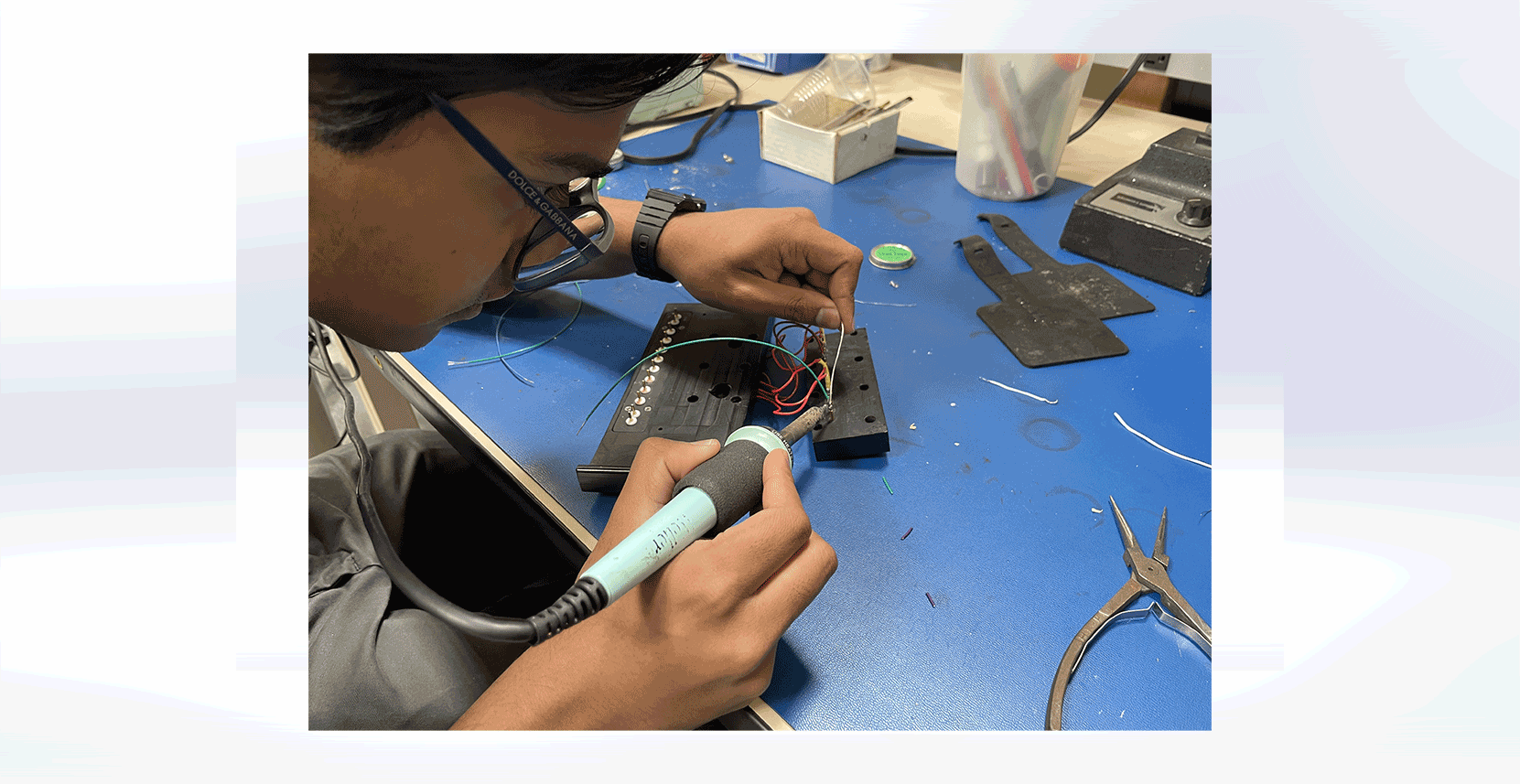

I developed an enhanced version of an electronic tool for sensors, featuring flying leads for injection into specific chemical tools. The project entailed machining, drilling, soldering electronic components, and integrating hinge and latch mechanisms.

Anodizing Tool with Flying Leads

Preparing to Solder Wires

Anodizing Tool CAD

Anodizing Tool CAD

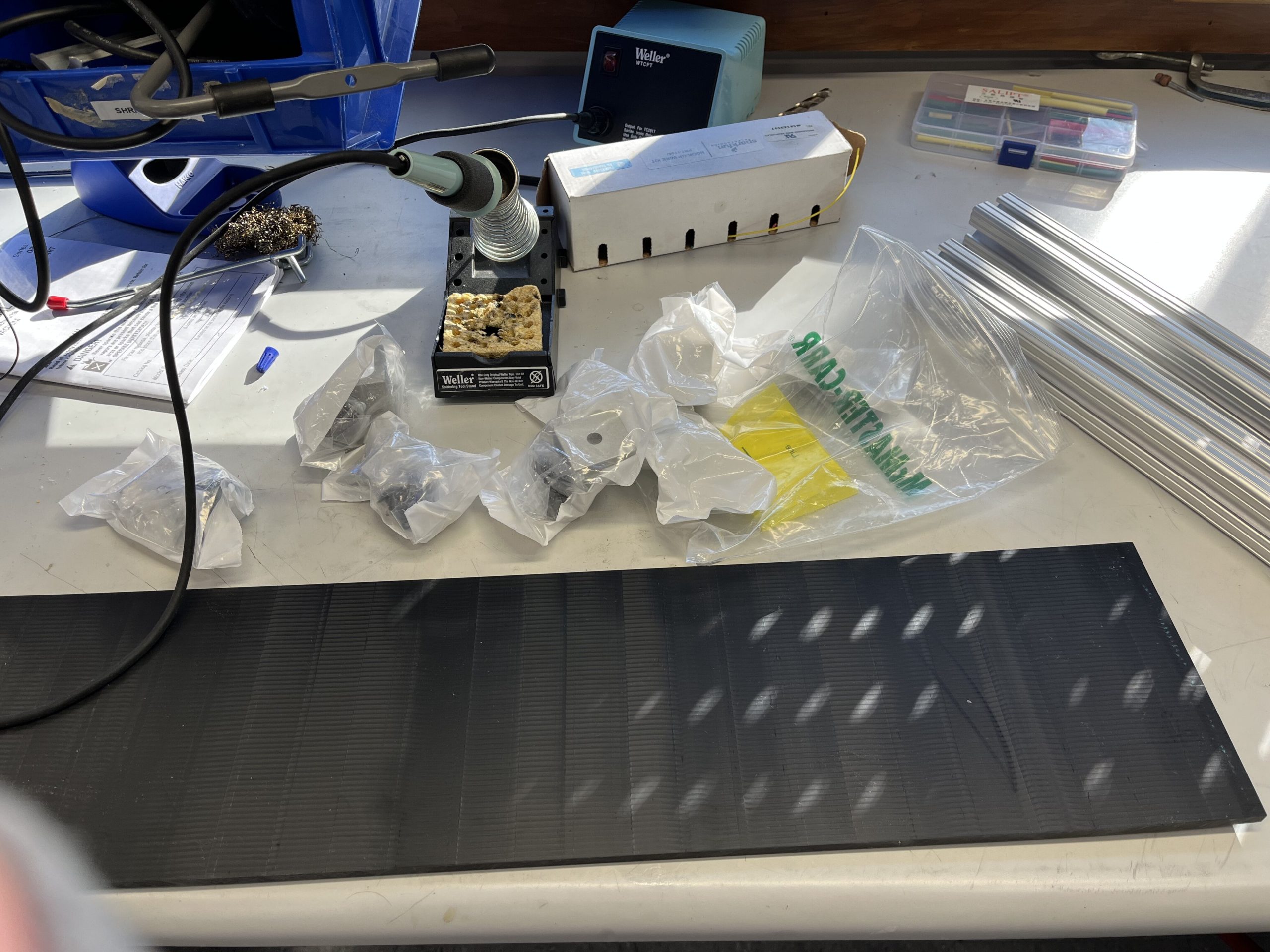

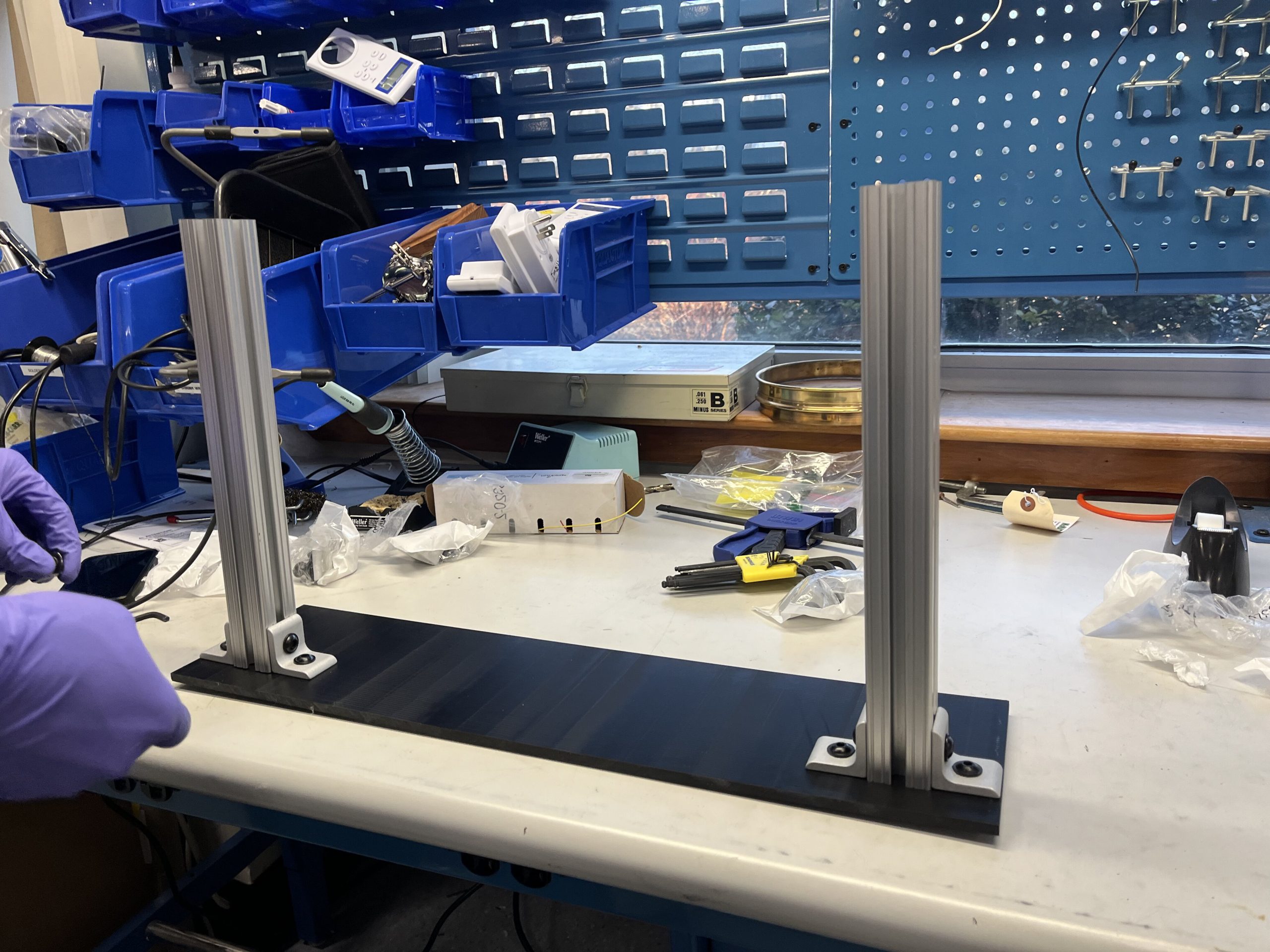

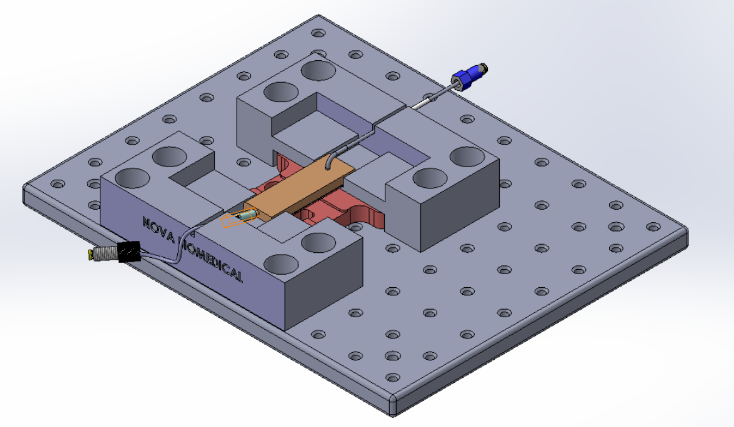

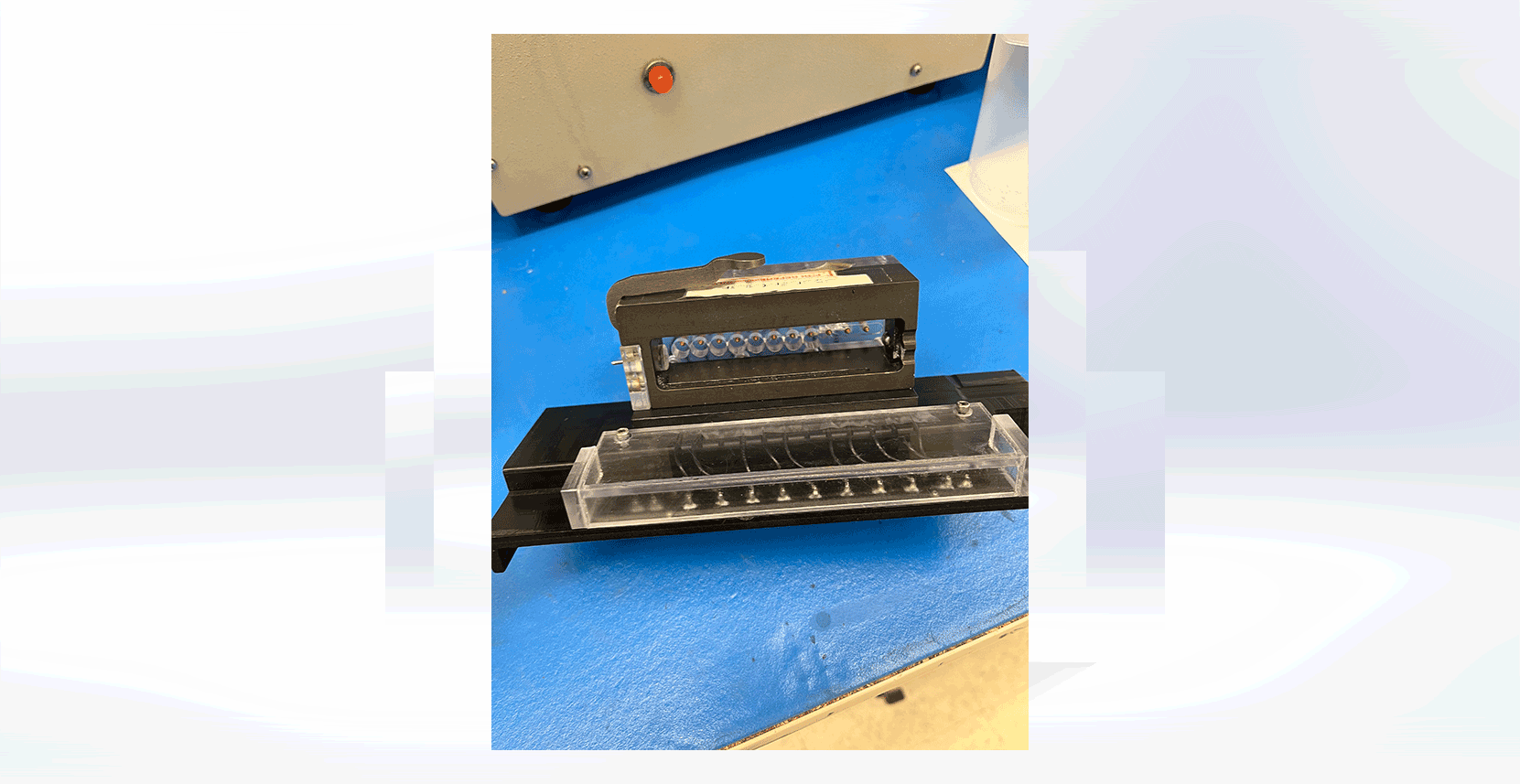

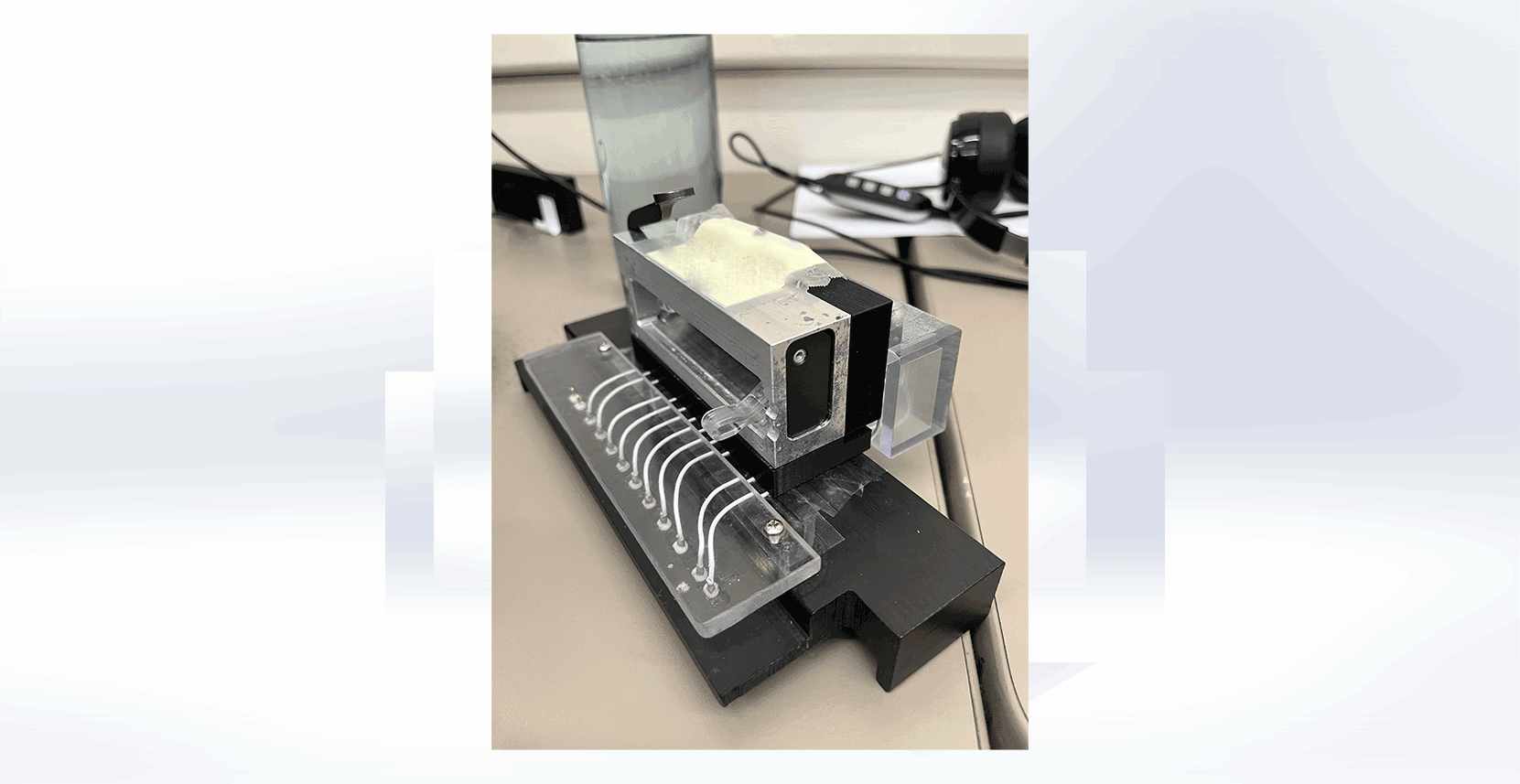

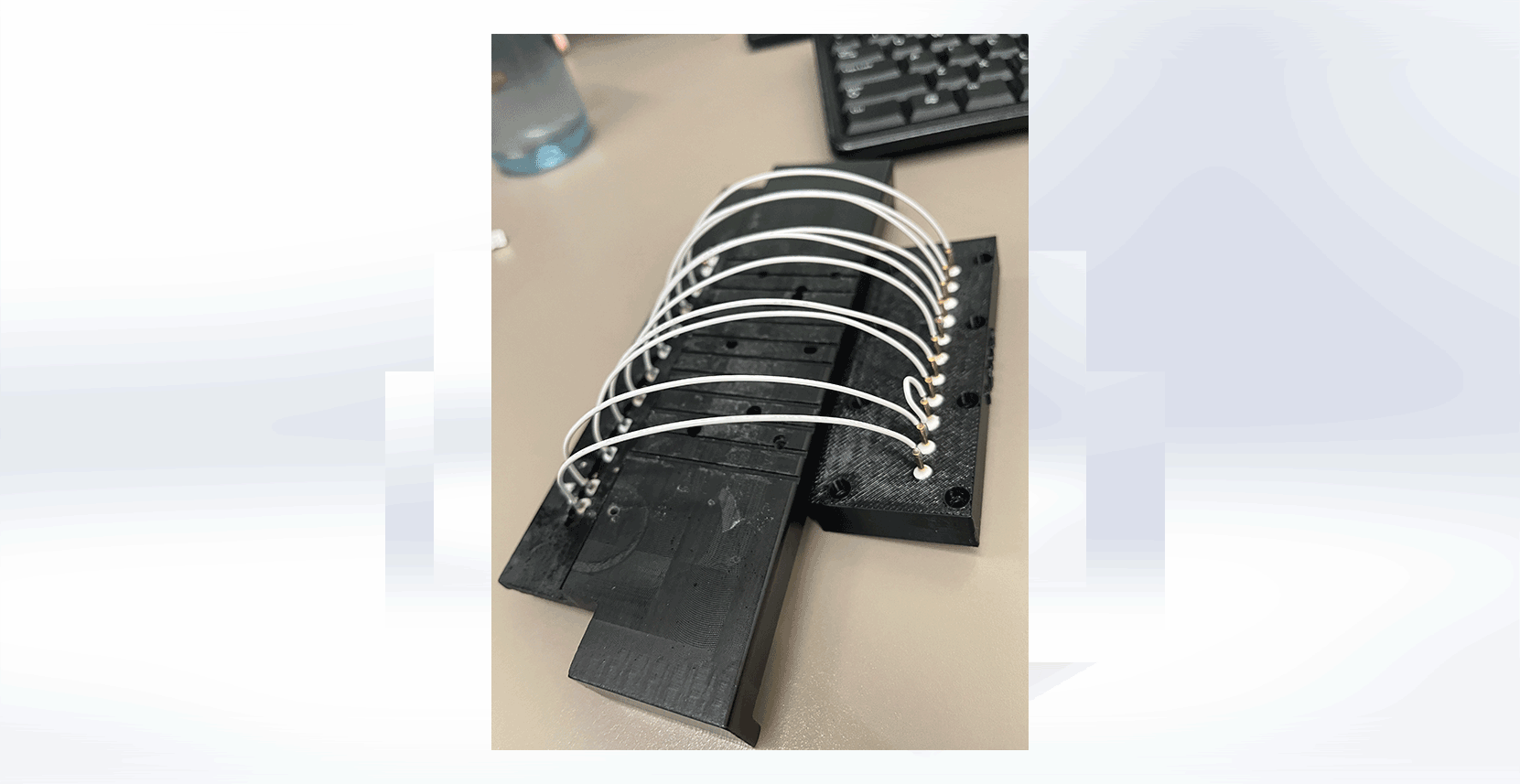

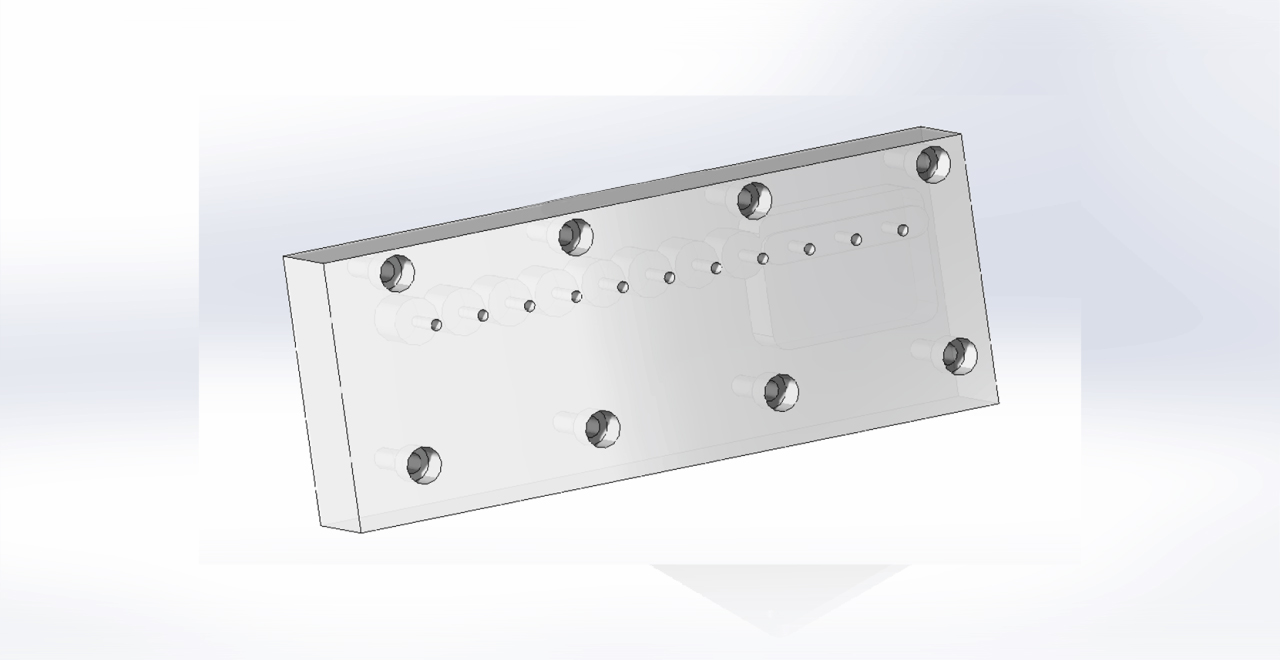

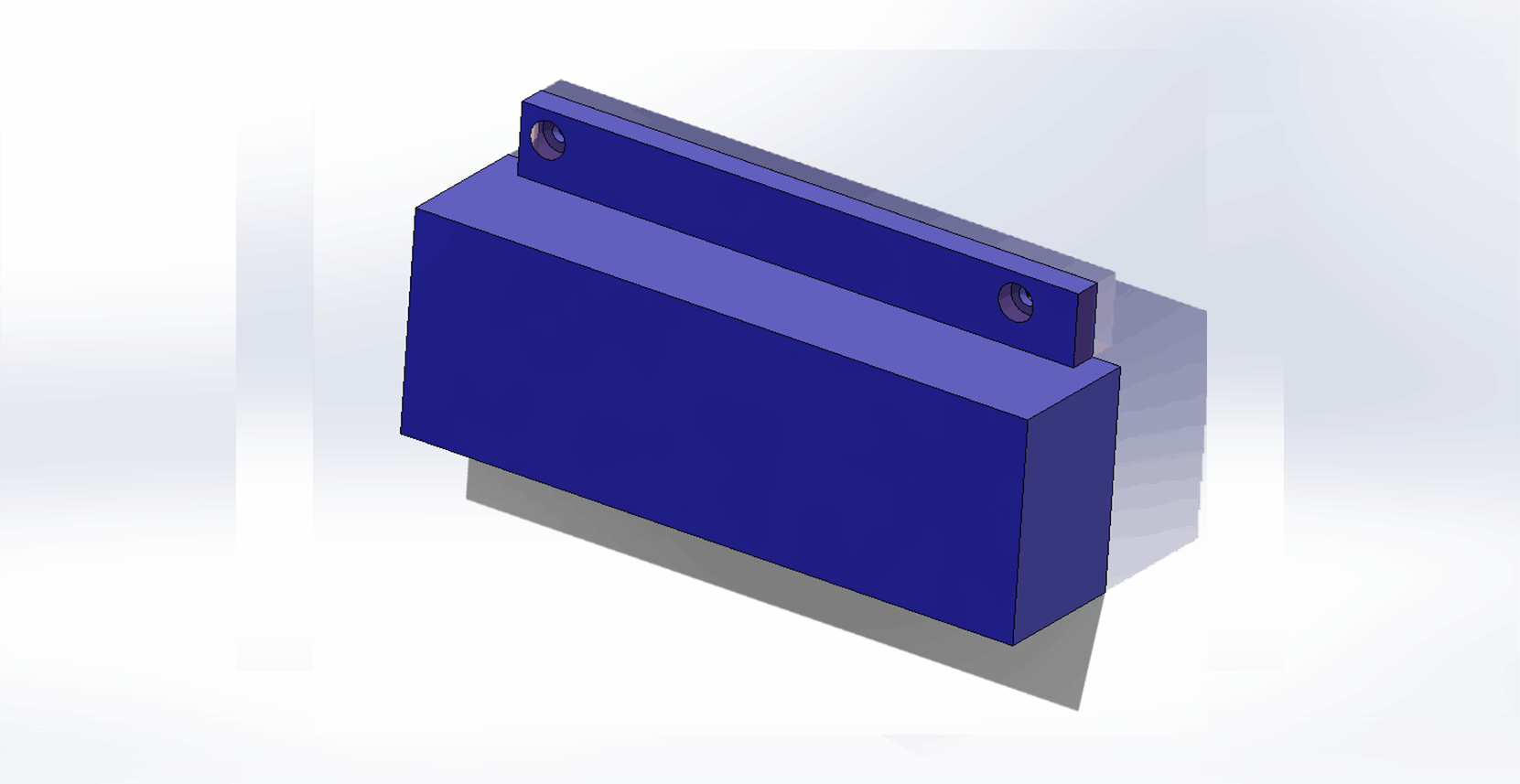

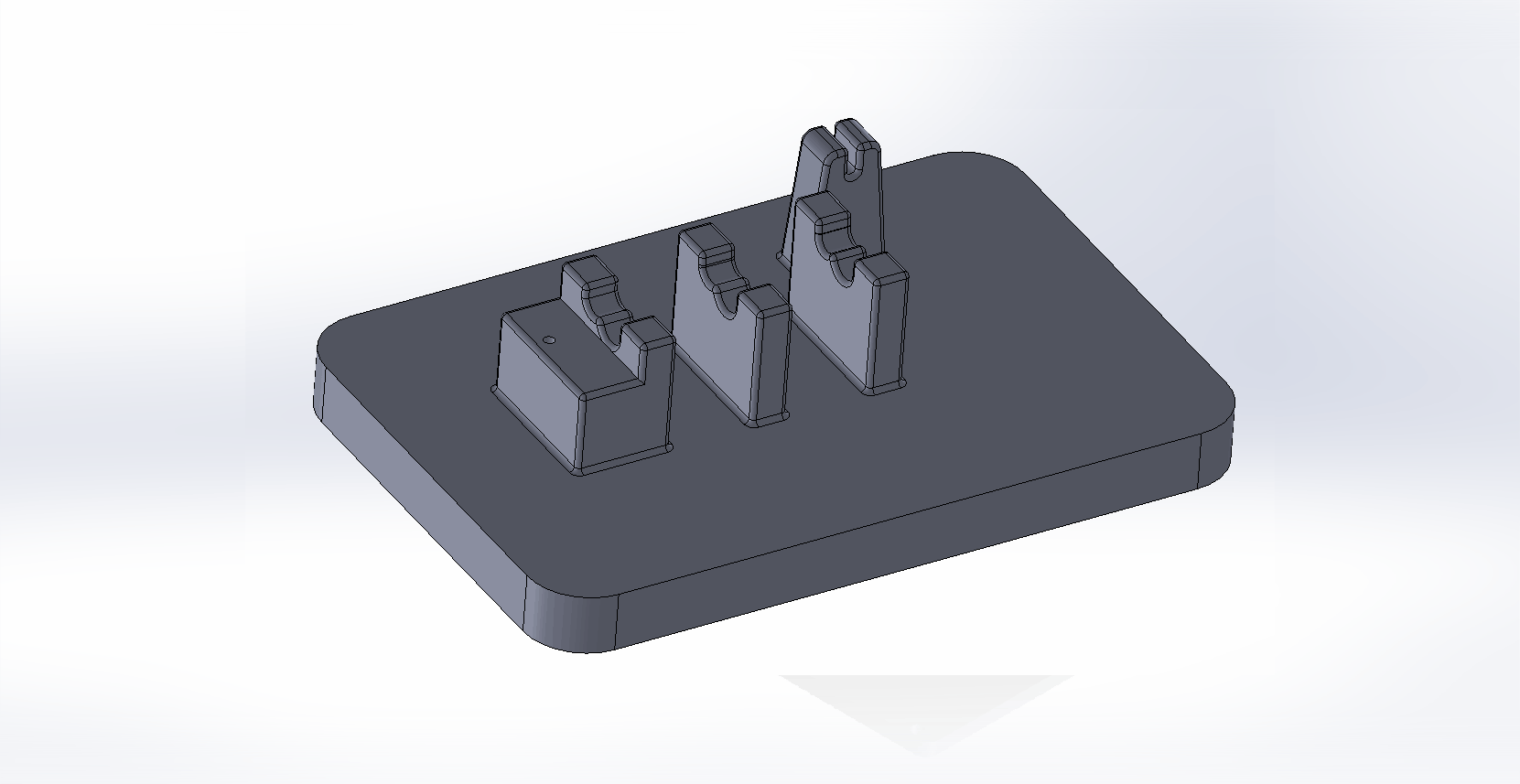

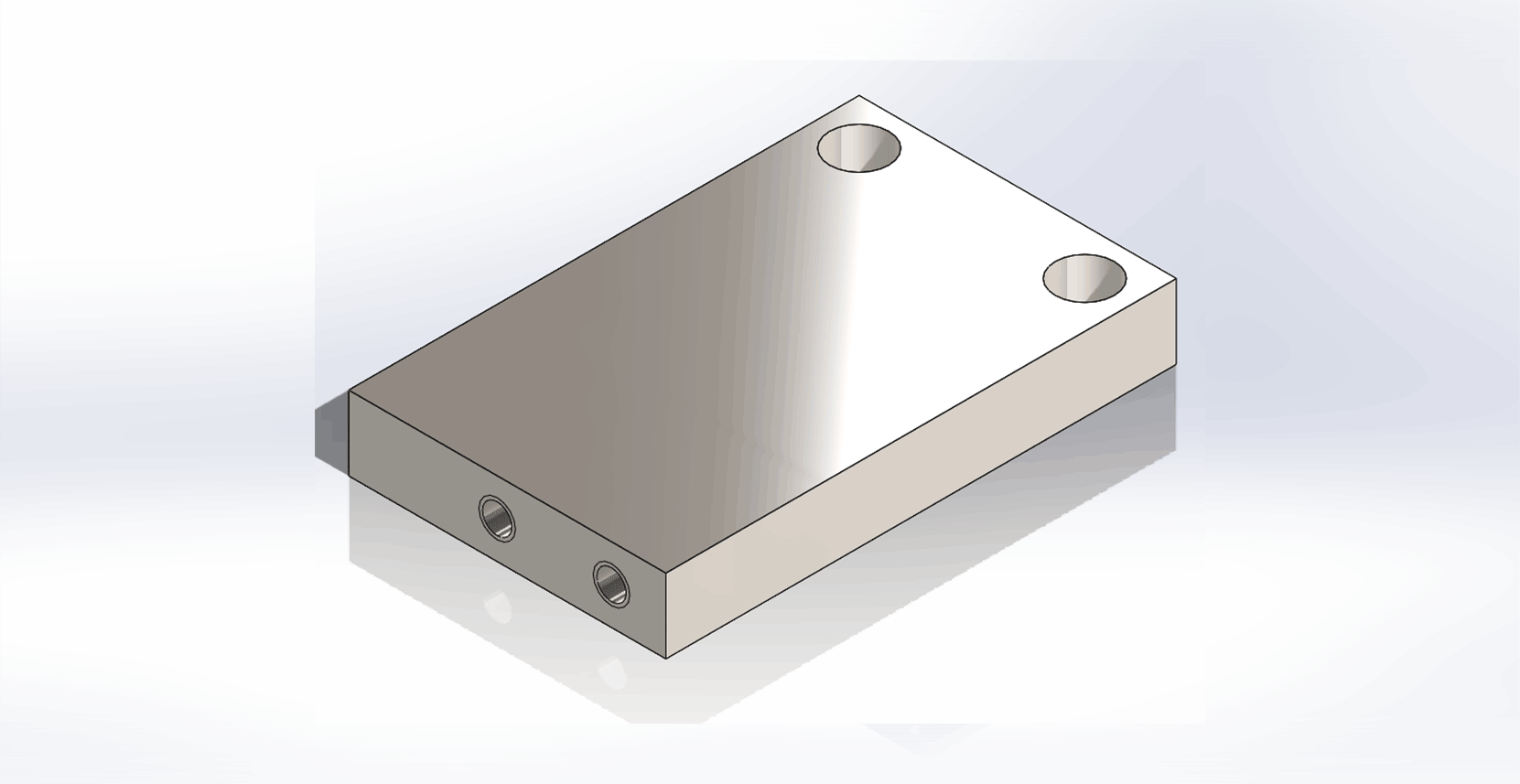

I tackled two versions of the Cartridge Fixture during my co-op. The project involved extensive modeling of new parts, resoldering press fit pins to pogo pins, and rigorous testing. By the end of the internship, I successfully completed the first variant, but the second variant passed only half of the examinations. I contributed by providing detailed steps to the engineering team for updating the assembly drawing based on the parts I created. Additionally, I assisted in determining the necessary testing procedures to rectify the issues with the second variant of the fixture.

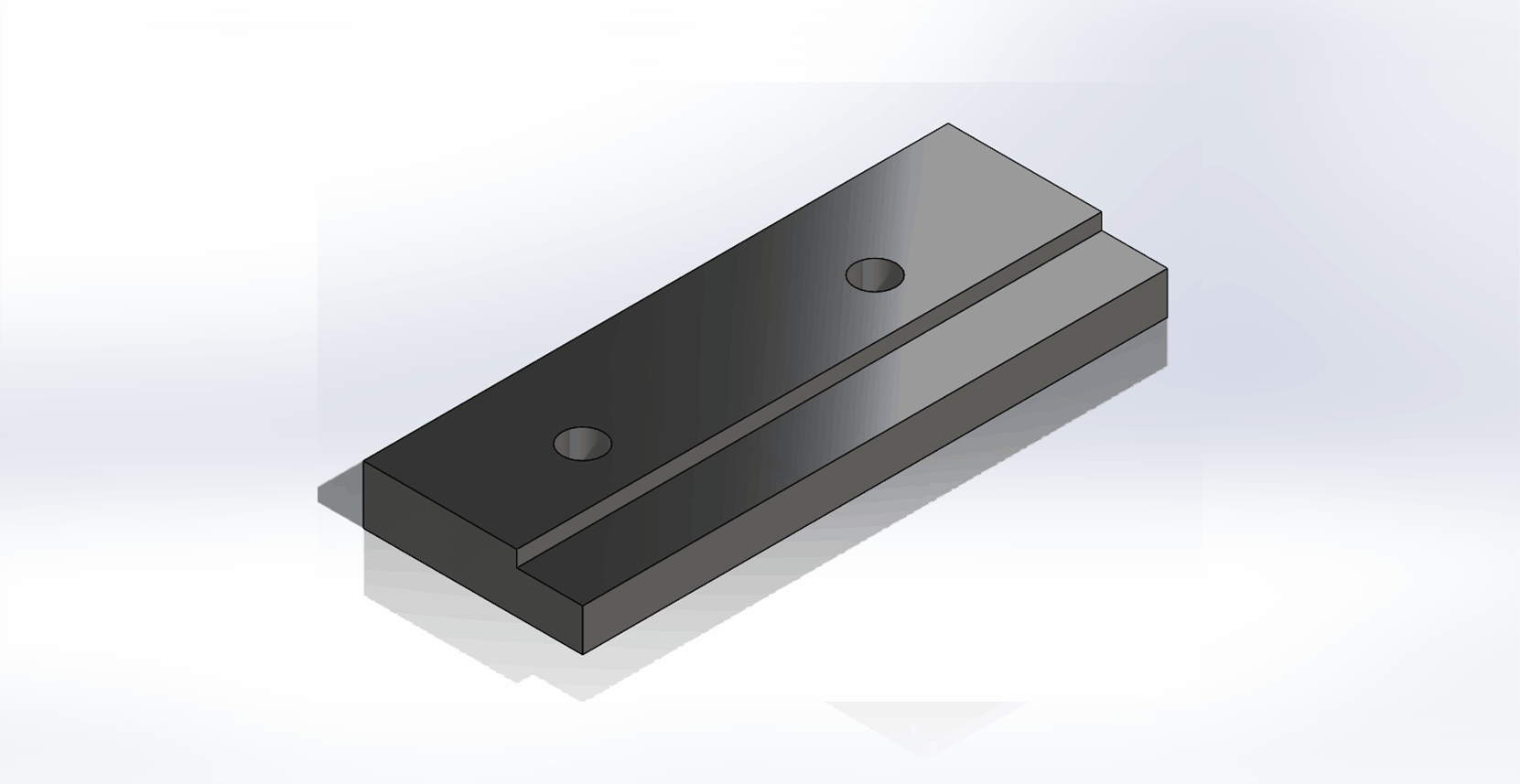

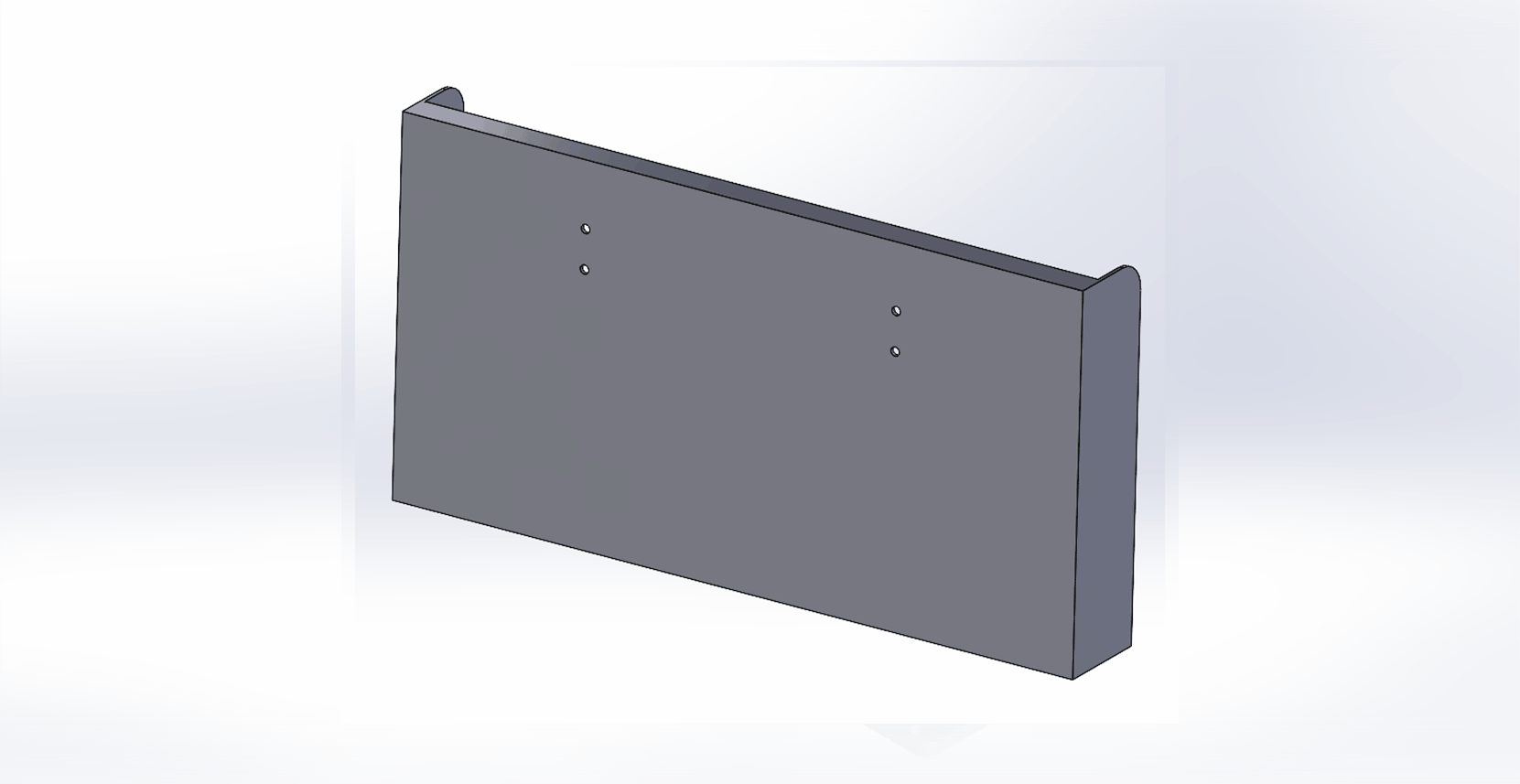

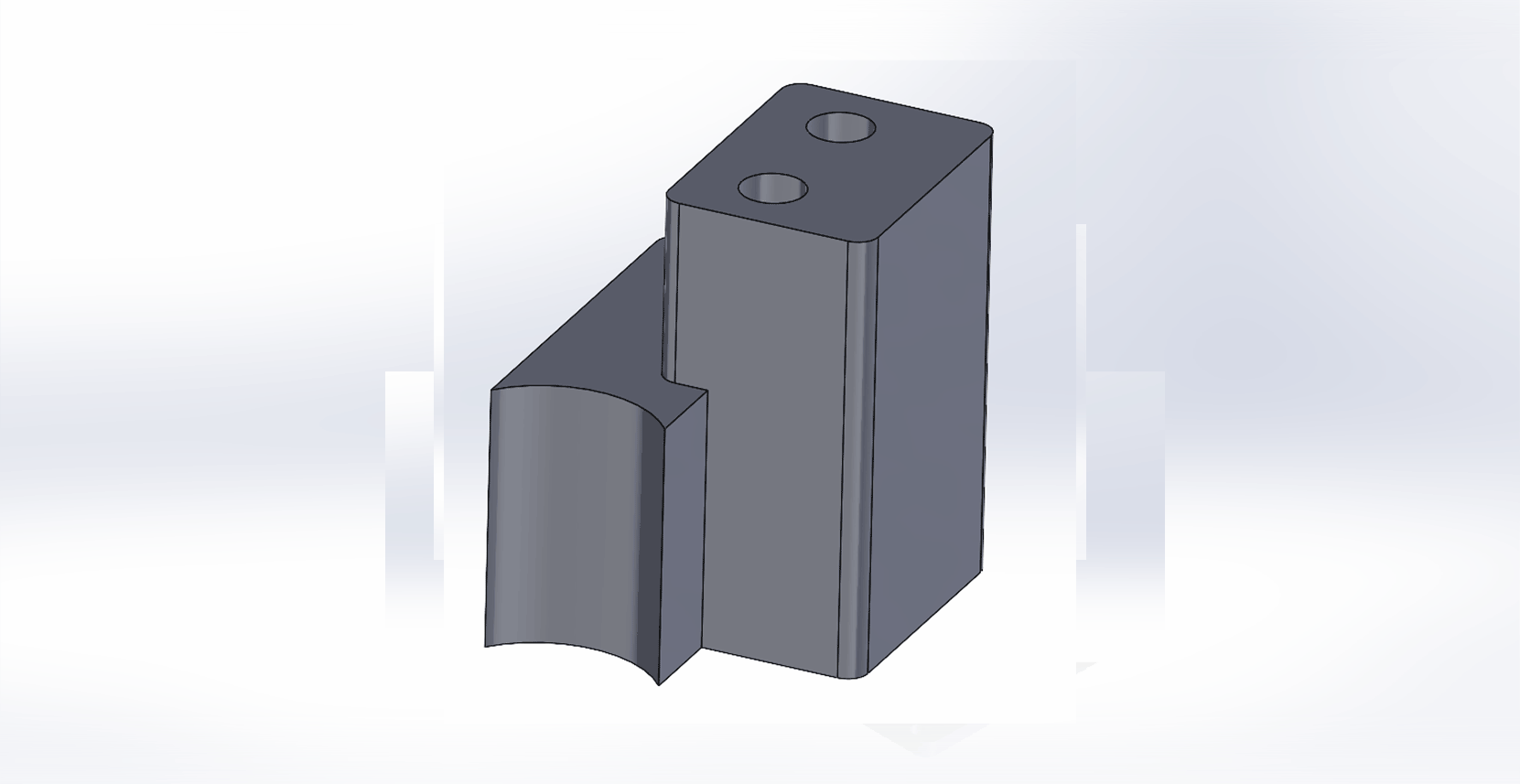

Bottom Base of Cartridge Fixtures CAD

Soldering Wires to Pins

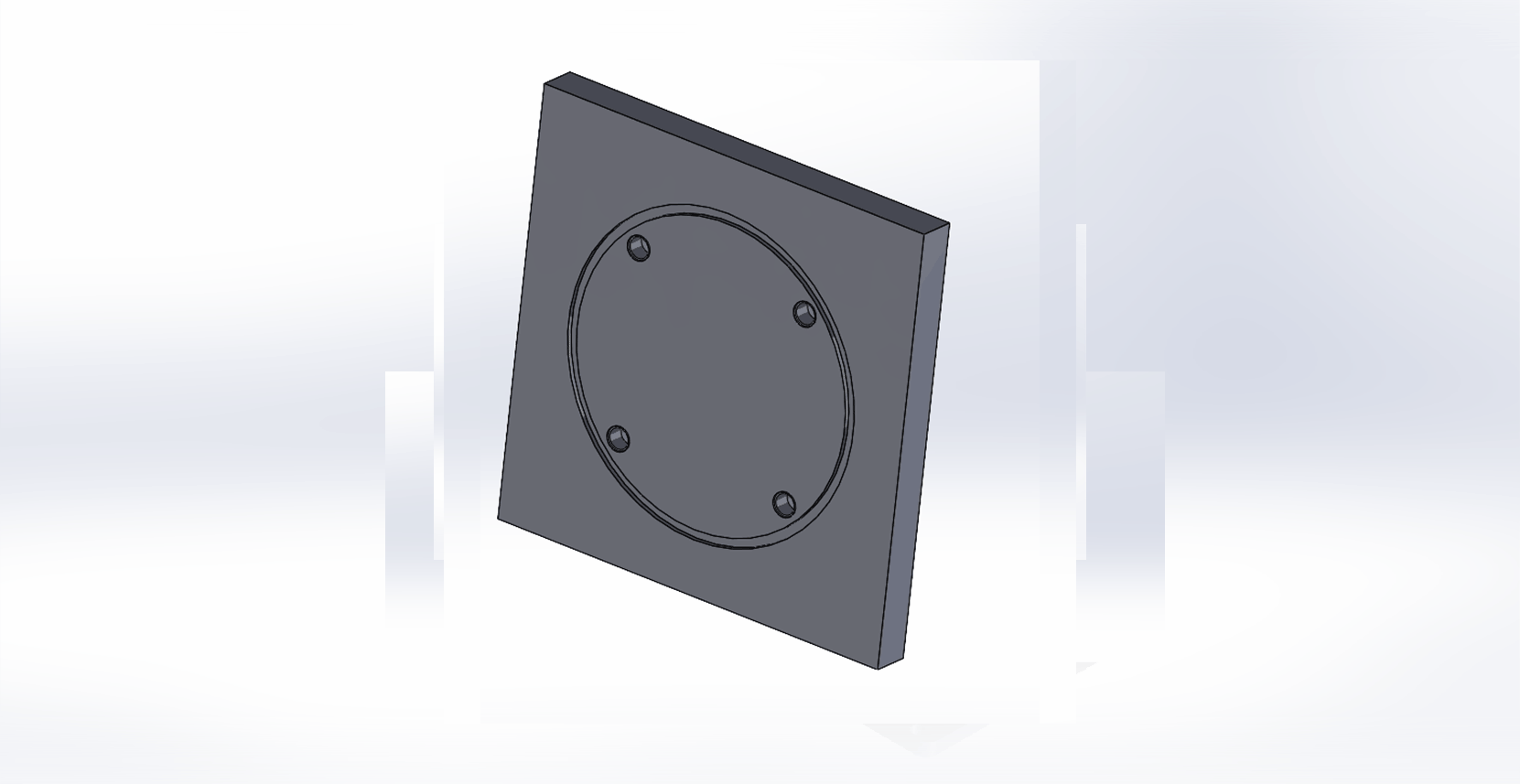

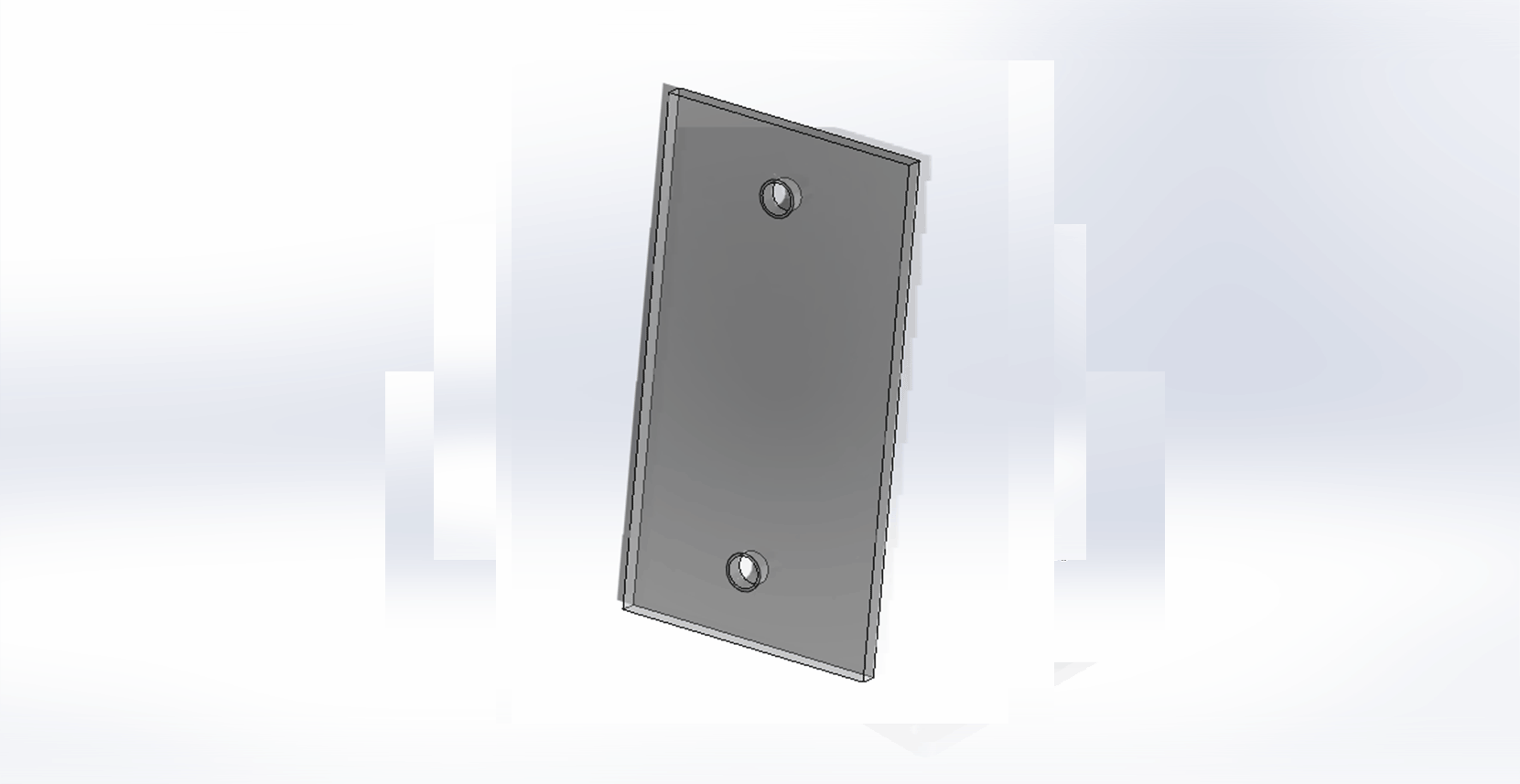

Base Plate of Cartridge Fixtures CAD

Variant 1 of Cartridge Fixture I assembled

Untitled-1

Wiring Pogo Pins to Press Fit Pins (Applied UV)

Bottom Base of Cartridge Fixtures CAD

Backplate for Pogo Pins CAD

ssdsddvsdv

Acrylic Wire Back Guard

DigiKey Pins I purchased

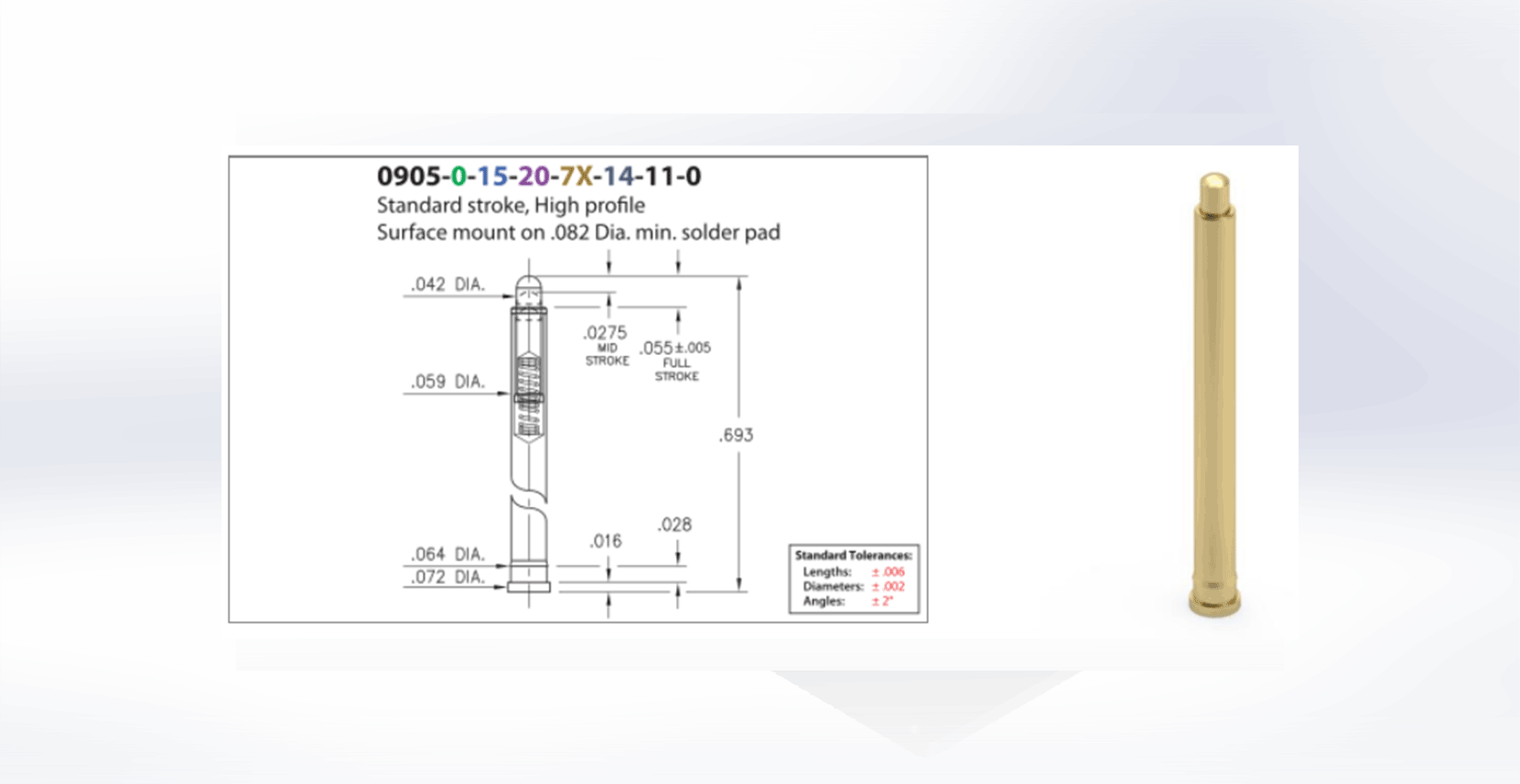

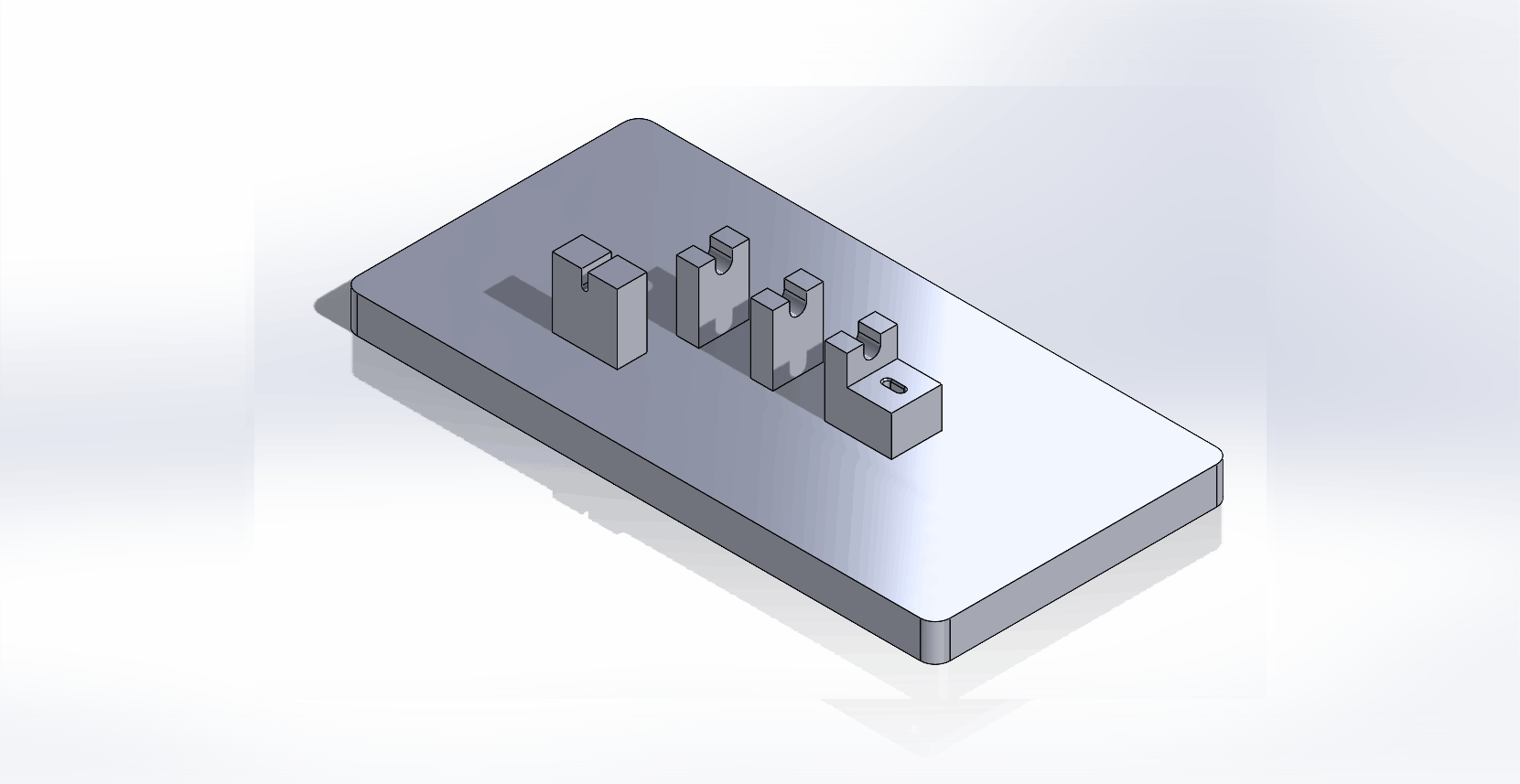

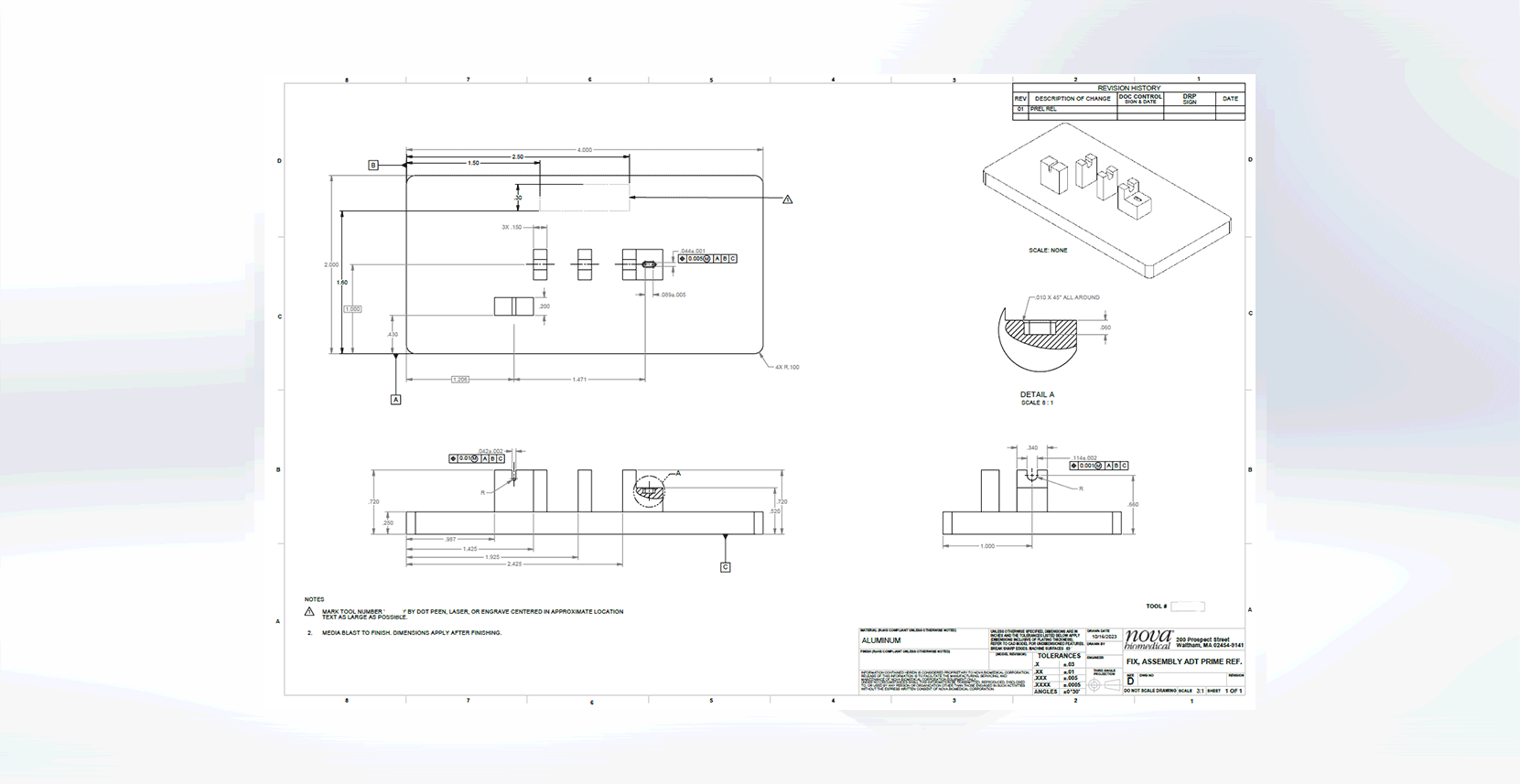

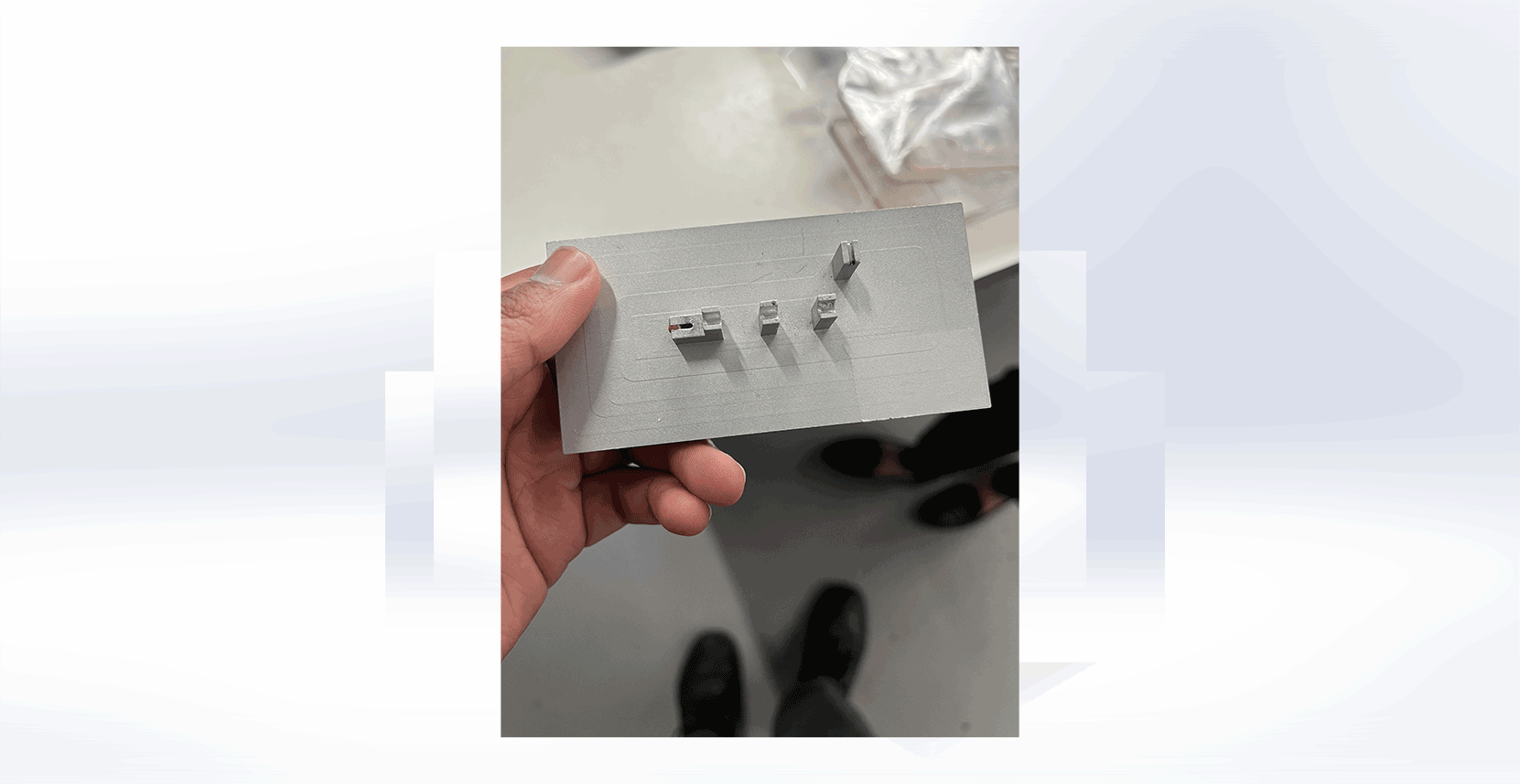

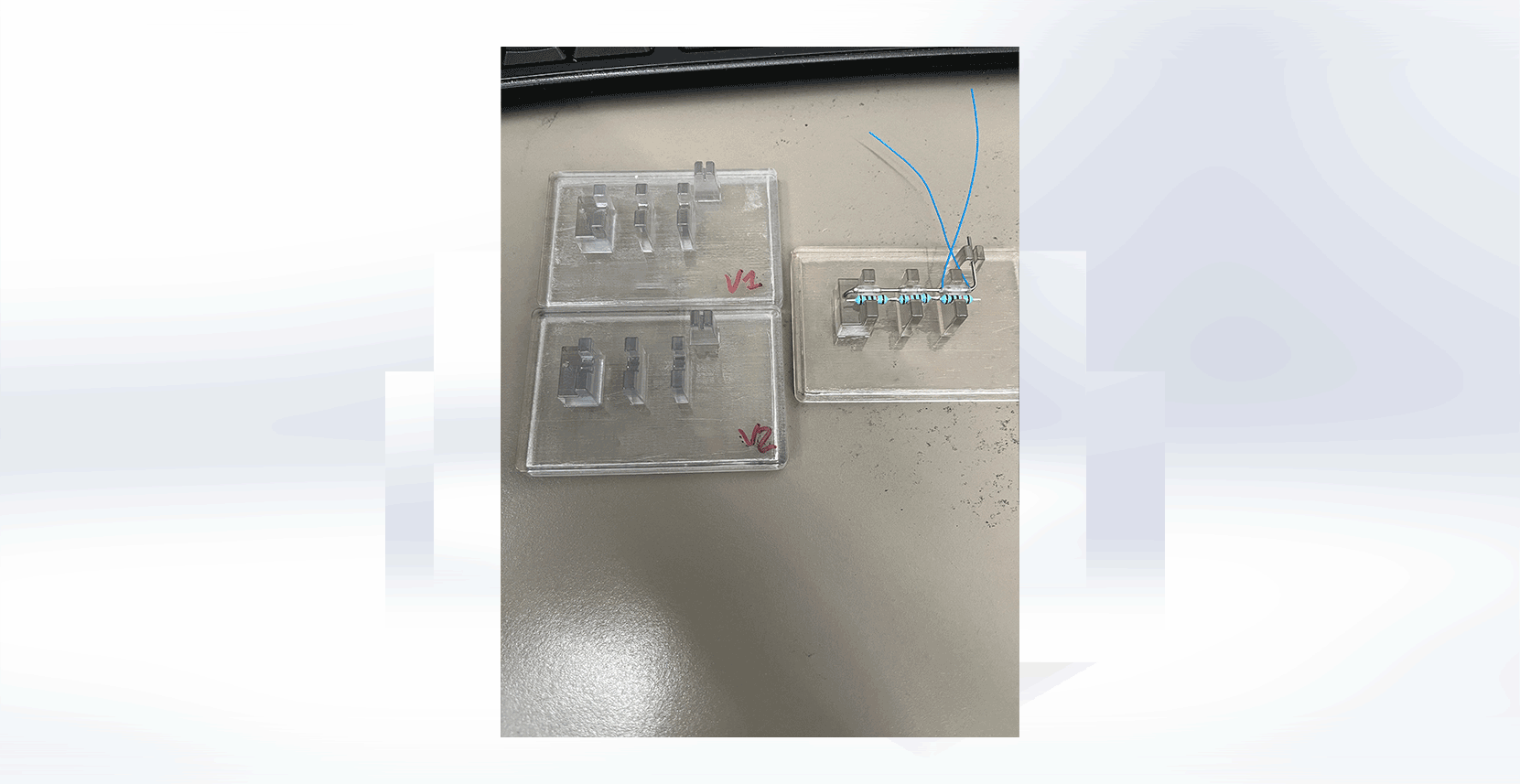

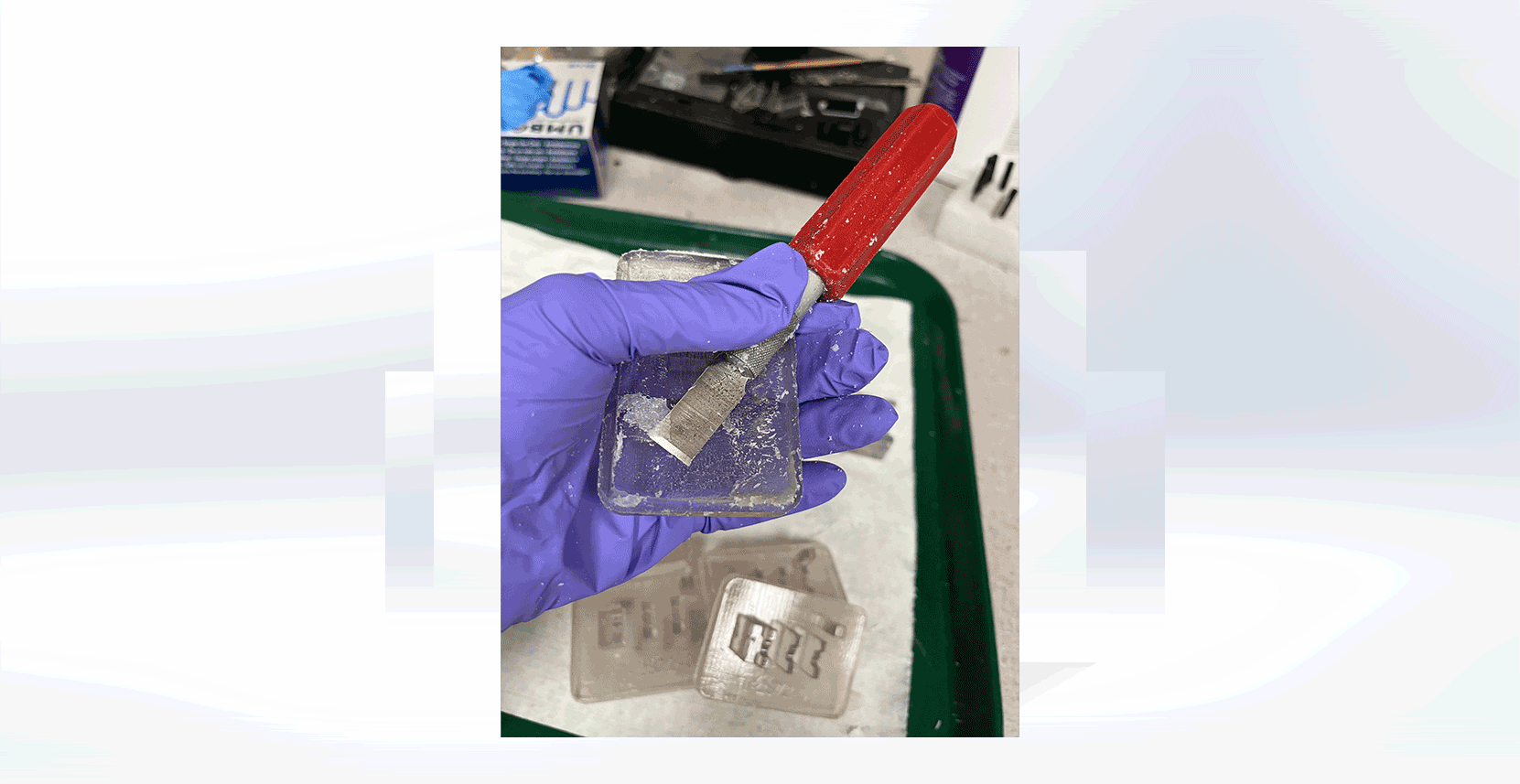

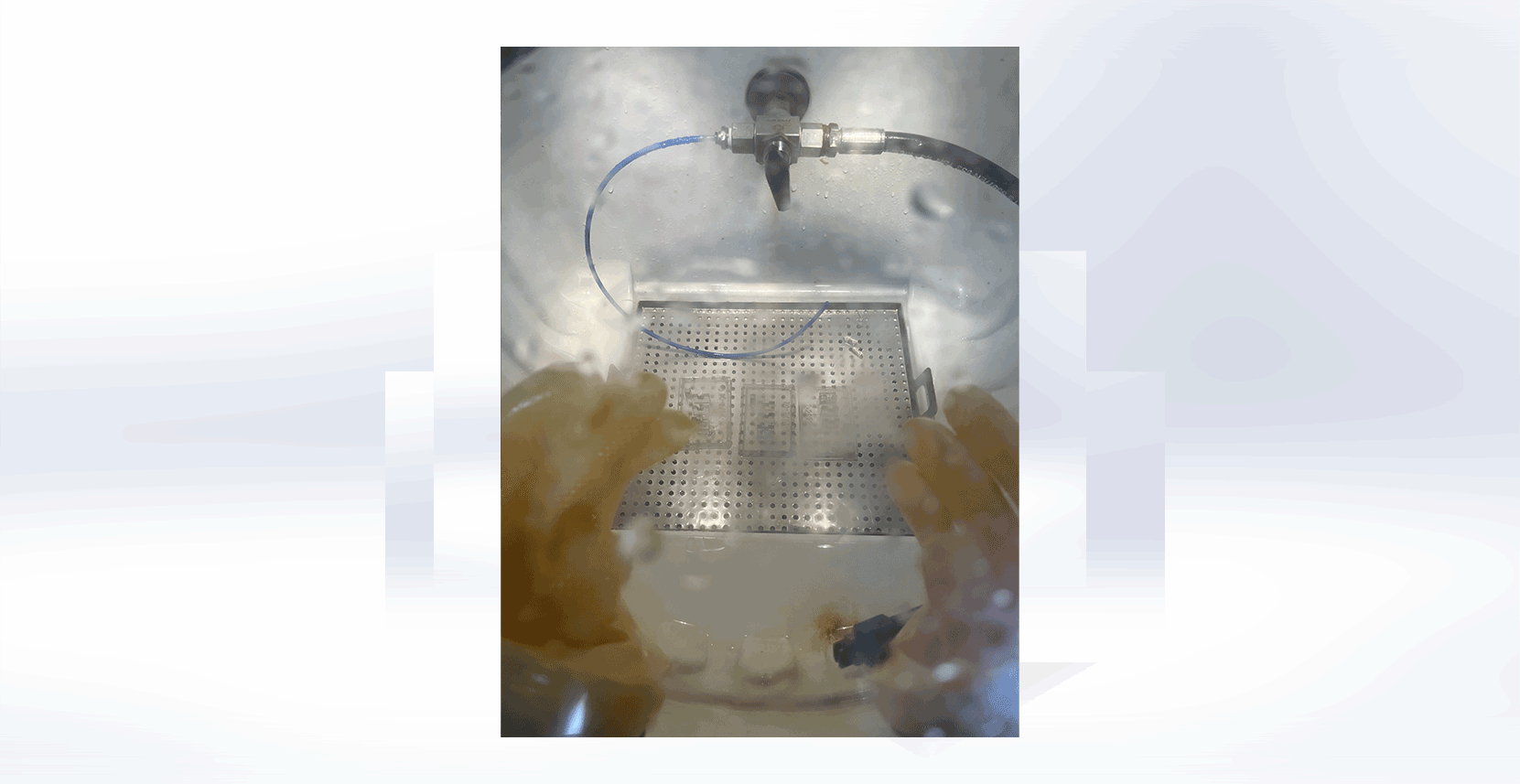

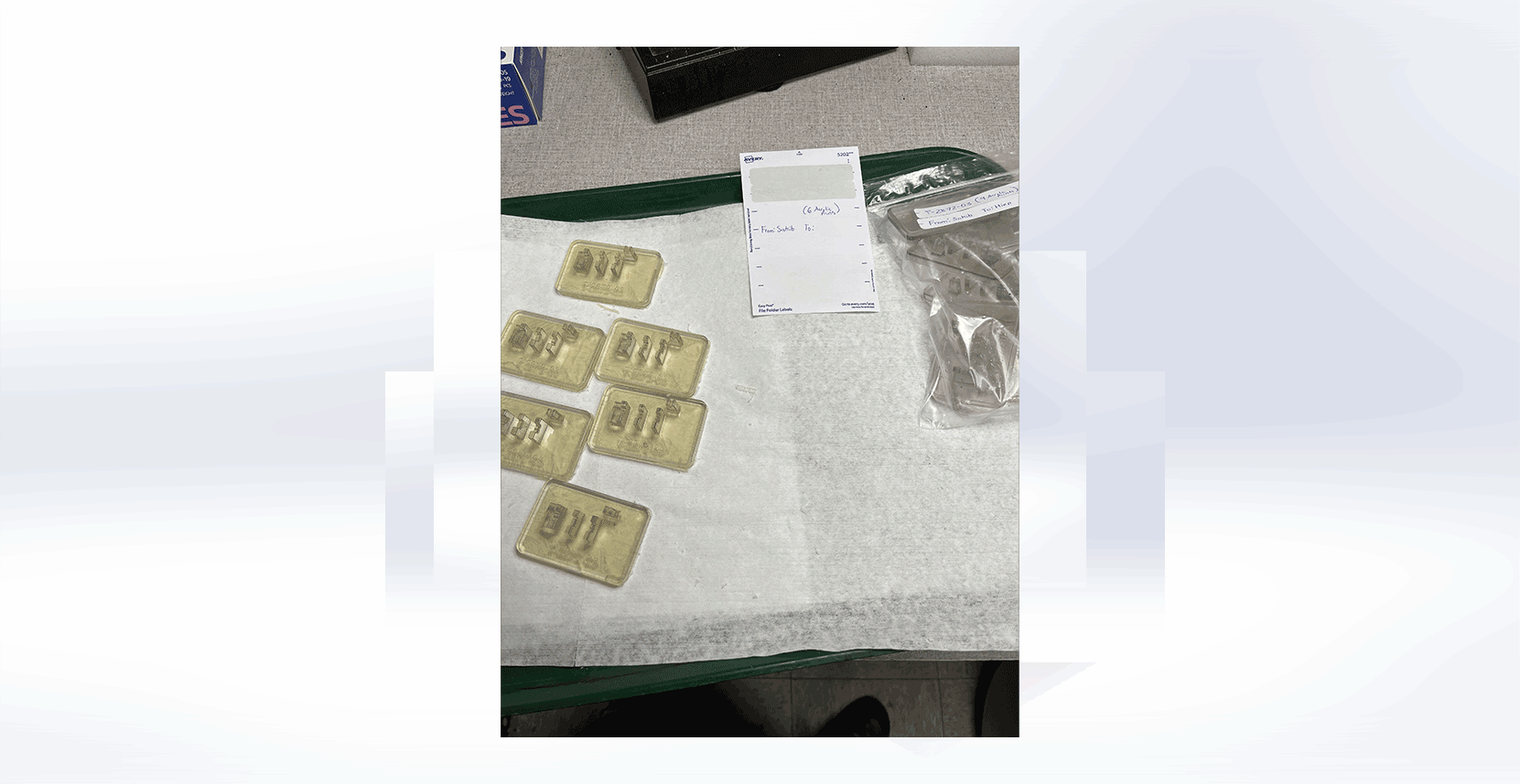

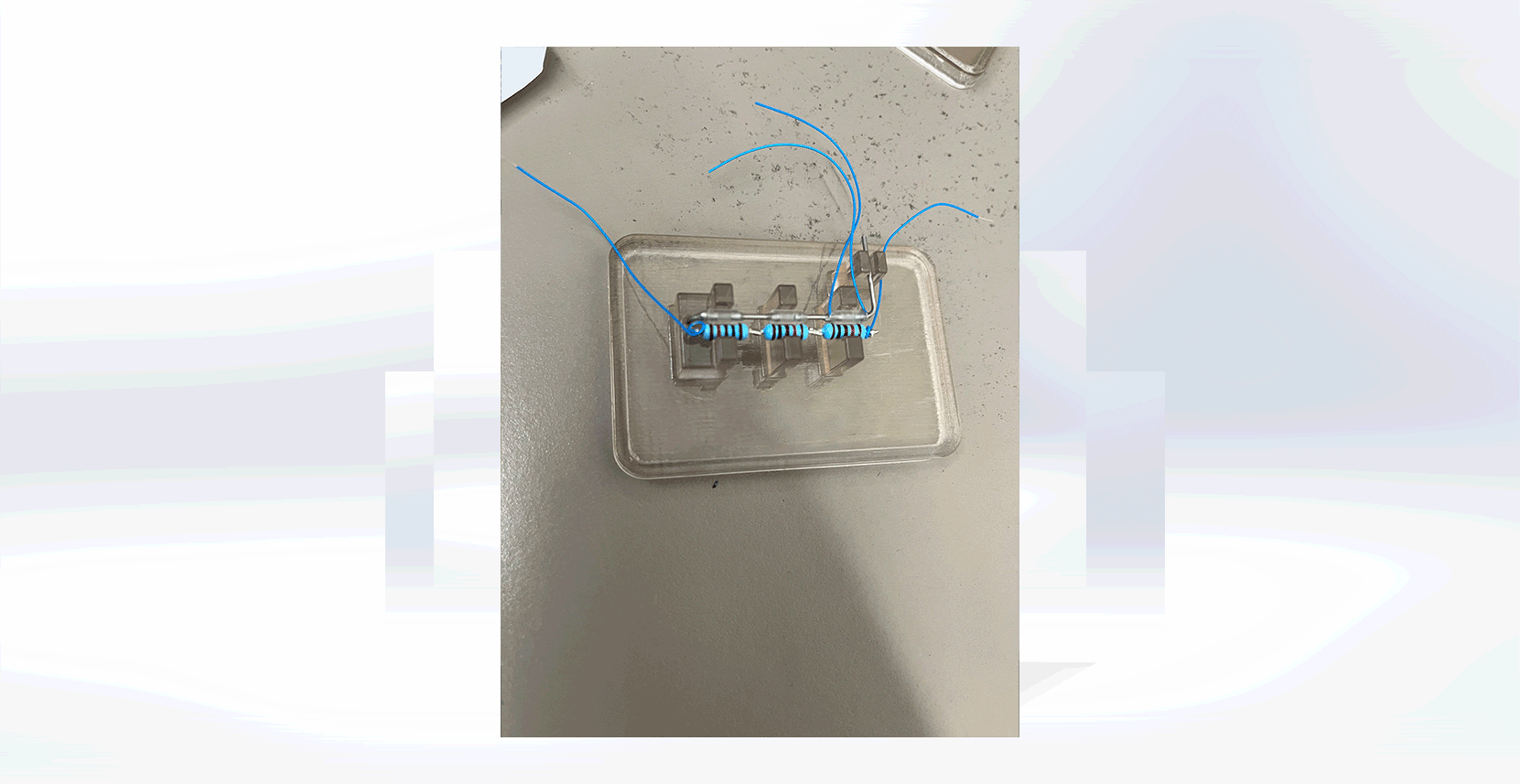

While at Nova, I designed and produced four ADT fixtures for various production lines. The first three fixtures, manufactured from 3D-printed acrylic, featured circular slots for mounting an ADT and resistors. Three different variants were created to accommodate distinct resistor types, involving the creation and cleaning of 80 acrylic units. The fourth fixture, exclusively designed for the ADT, was crafted from aluminum. The production process included machining 10 units of this fixture, incorporating geometric dimensioning and tolerancing (GD&T).

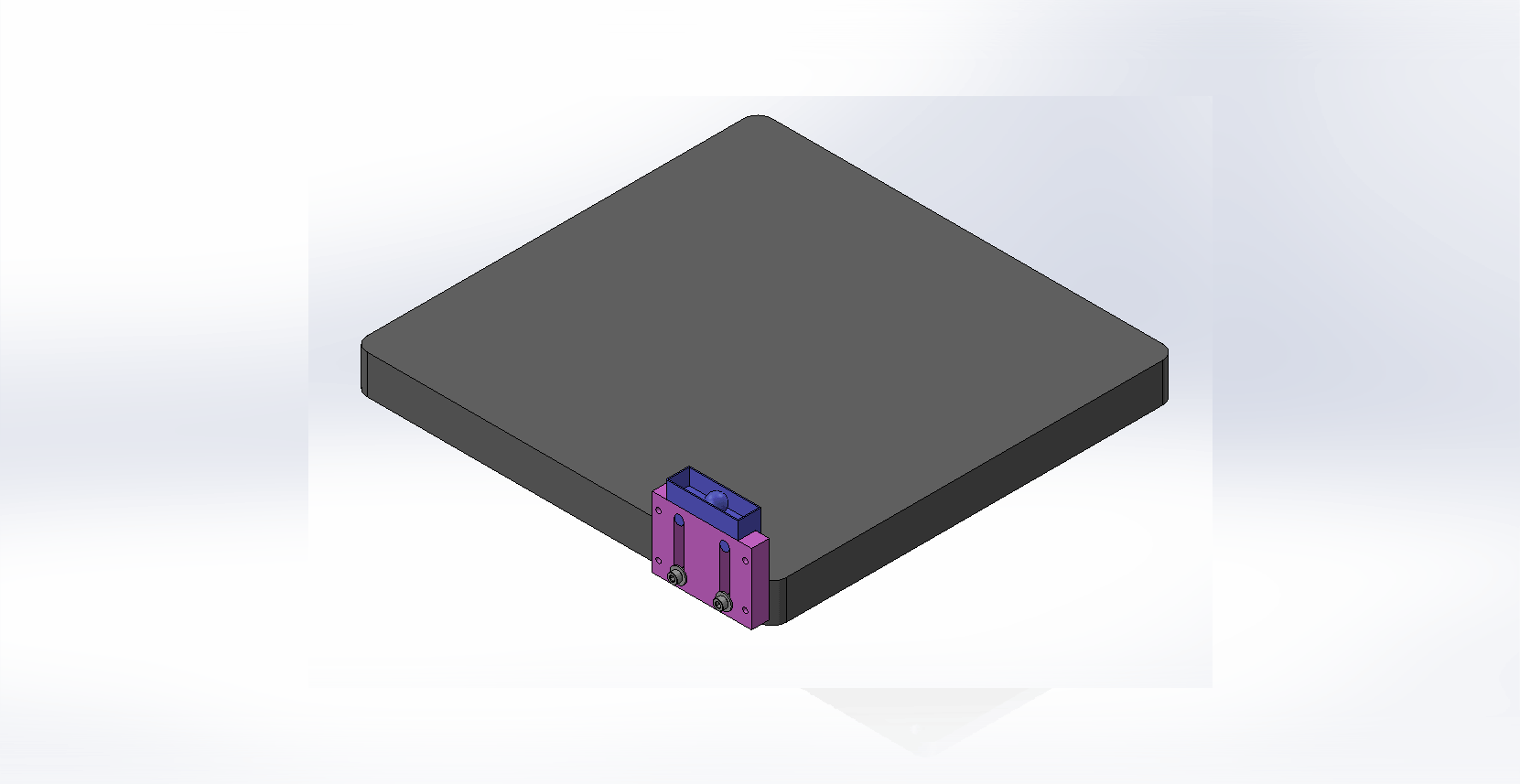

ADT Acrylic Fixture (has 3 variants) CAD

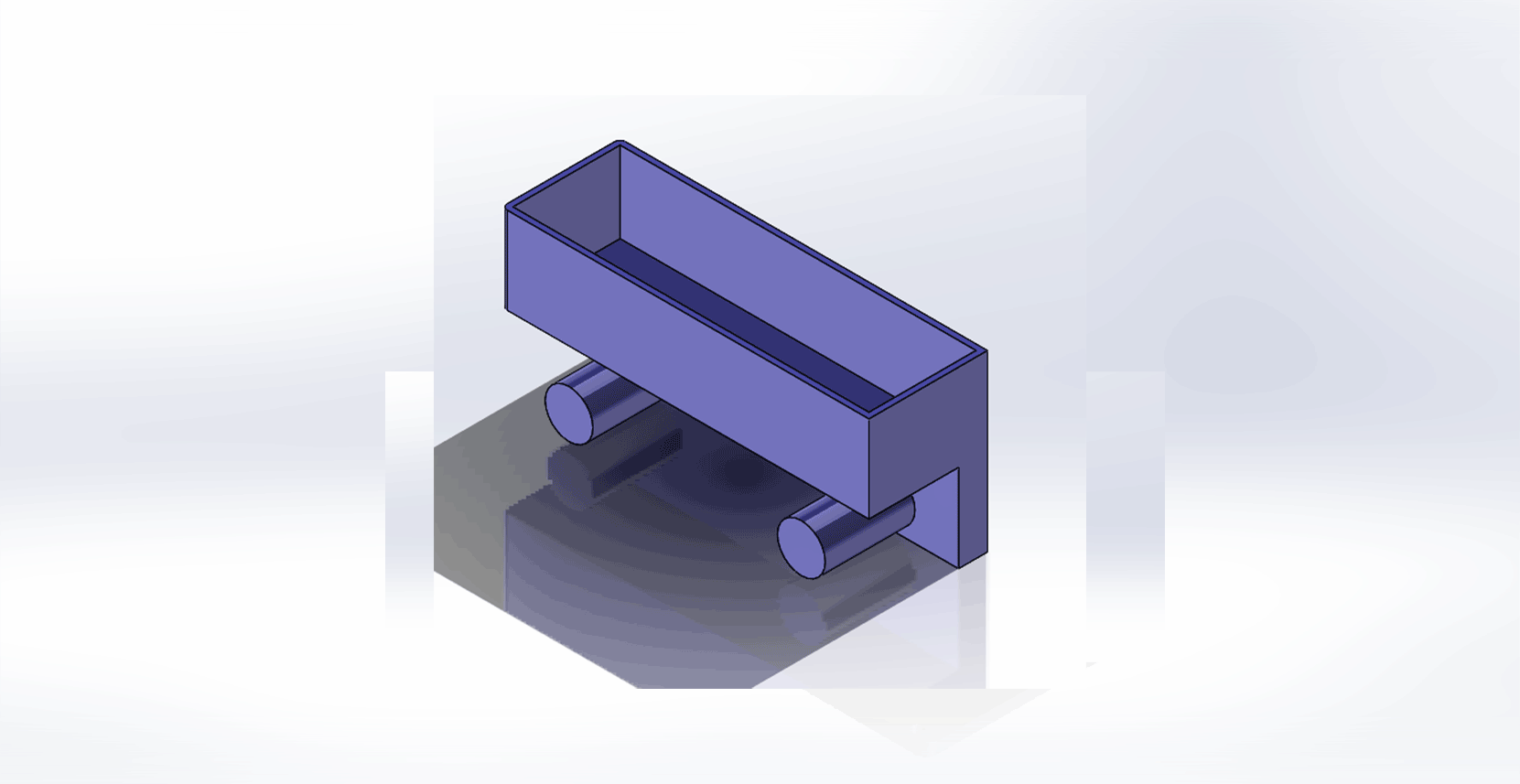

Fourth ADT Fixture CAD

Fourth ADT Fixture GD & T Drawing

Machined Aluminum Fourth ADT Fixture

Failed Designs since resistors wouldn’t fit

Removing Support Material under Acrylic Fixtures

Bagging 10 of 80 Acrylic Fixtures Cleaned

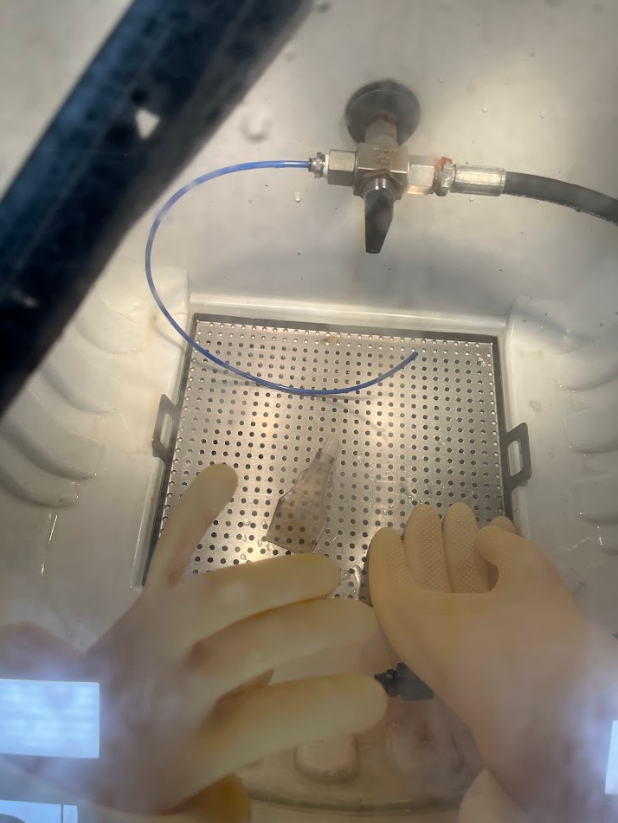

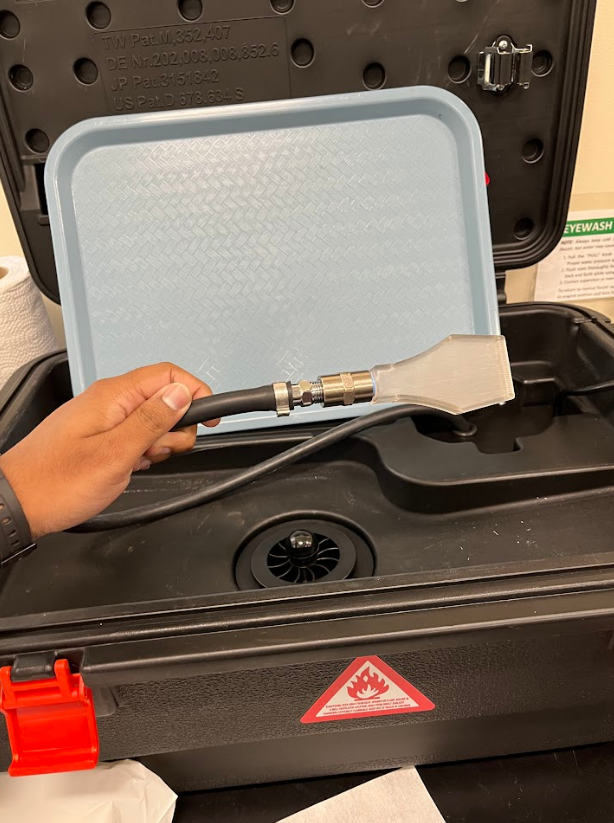

Pressure Washing Acrylic Fixtures

3D prints prepping for cleaning

: Perfect Resistor Fit

At the heart of the data collection process for the Allegro machines, there was an issue with the clay balls constantly falling off. To address this, I designed and implemented a specialized cup assembly that effectively captures the clay, enhancing the overall functionality and reliability of the system. Additionally, I facilitated the replication of this cup design by creating an engineering change order, tool number, and drawing number for the benefit of chemical engineers.

Clay Cup Assembly CAD

Clay Cup CAD

Acrylic Cup with Clay

Clay Cup in Machine

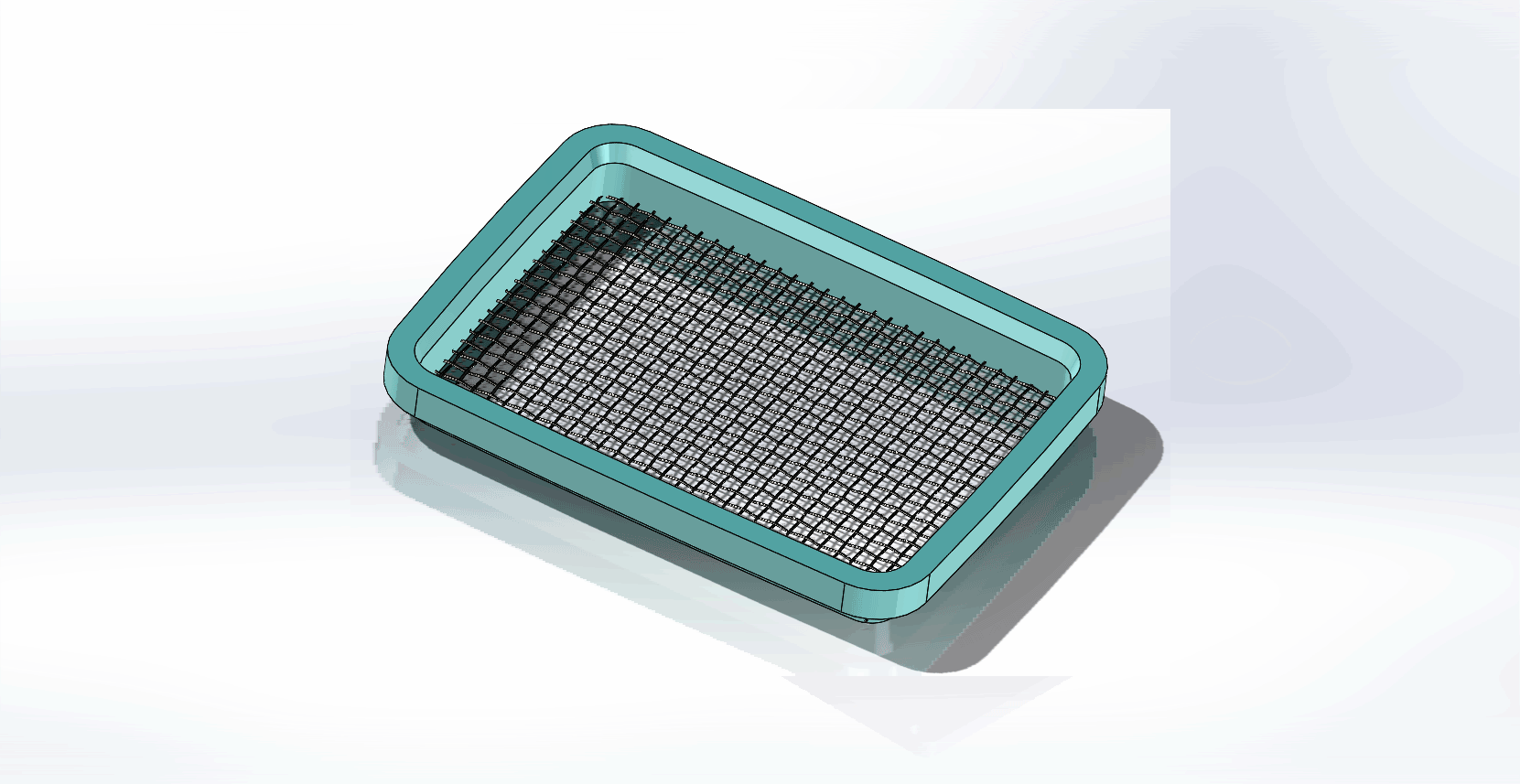

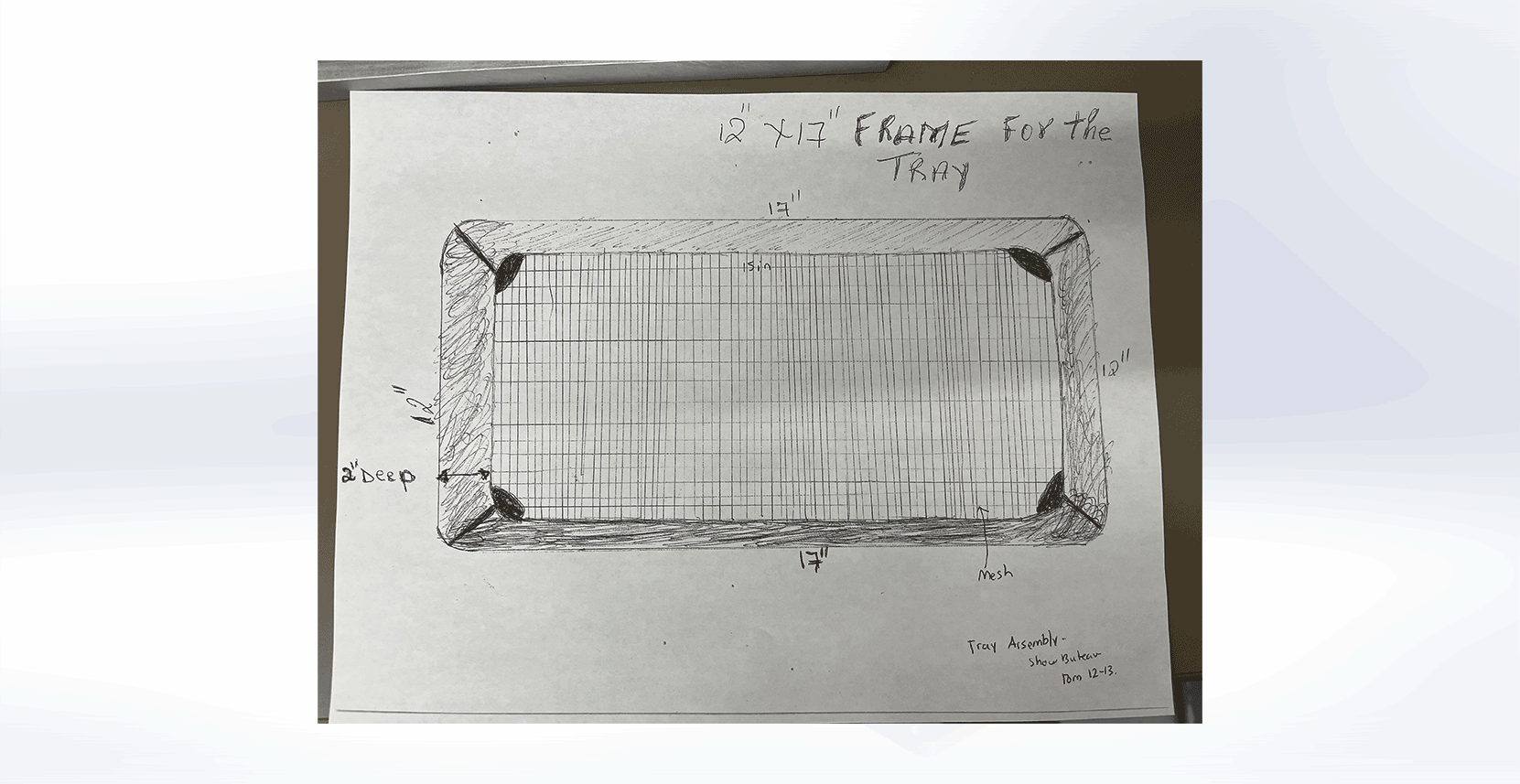

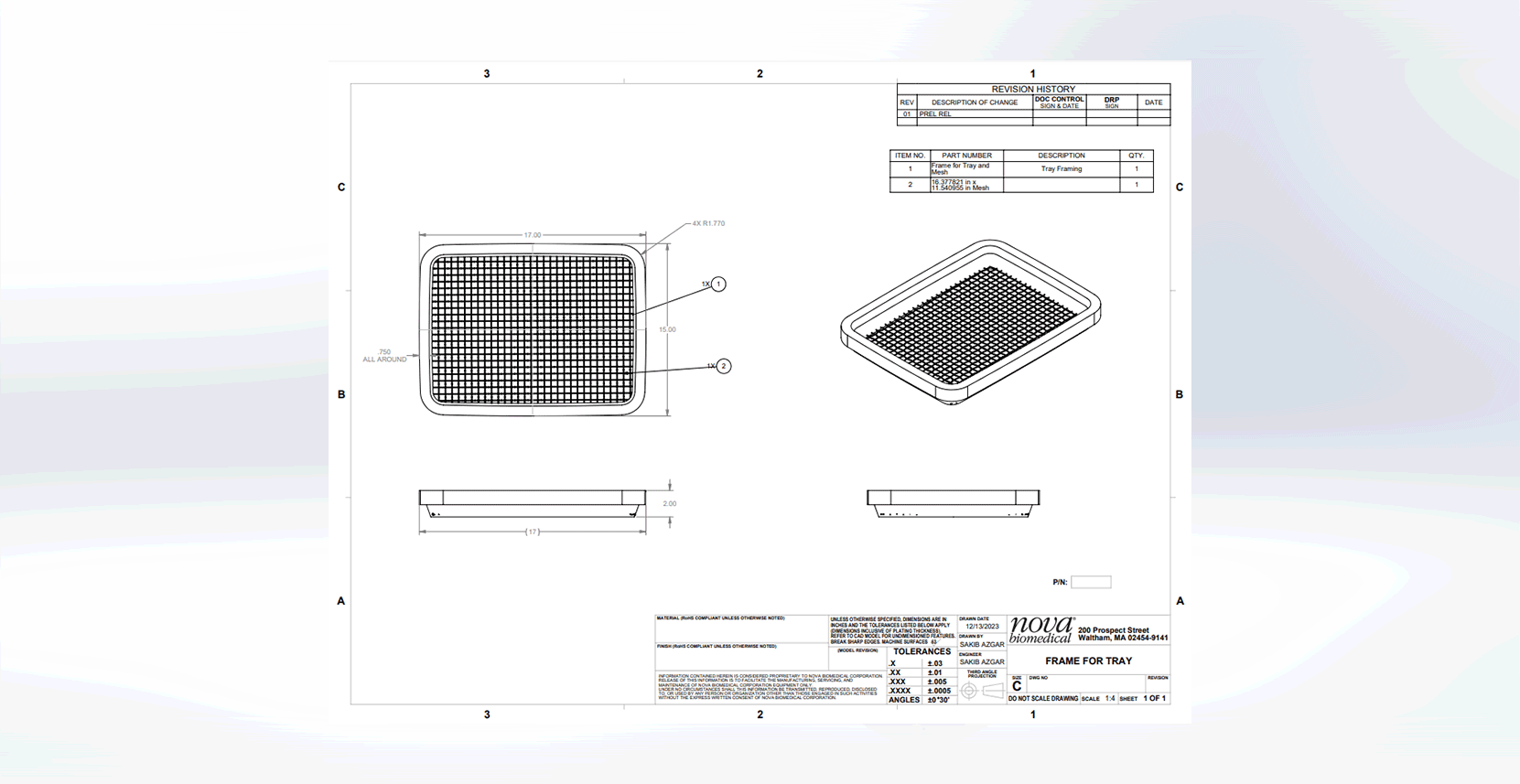

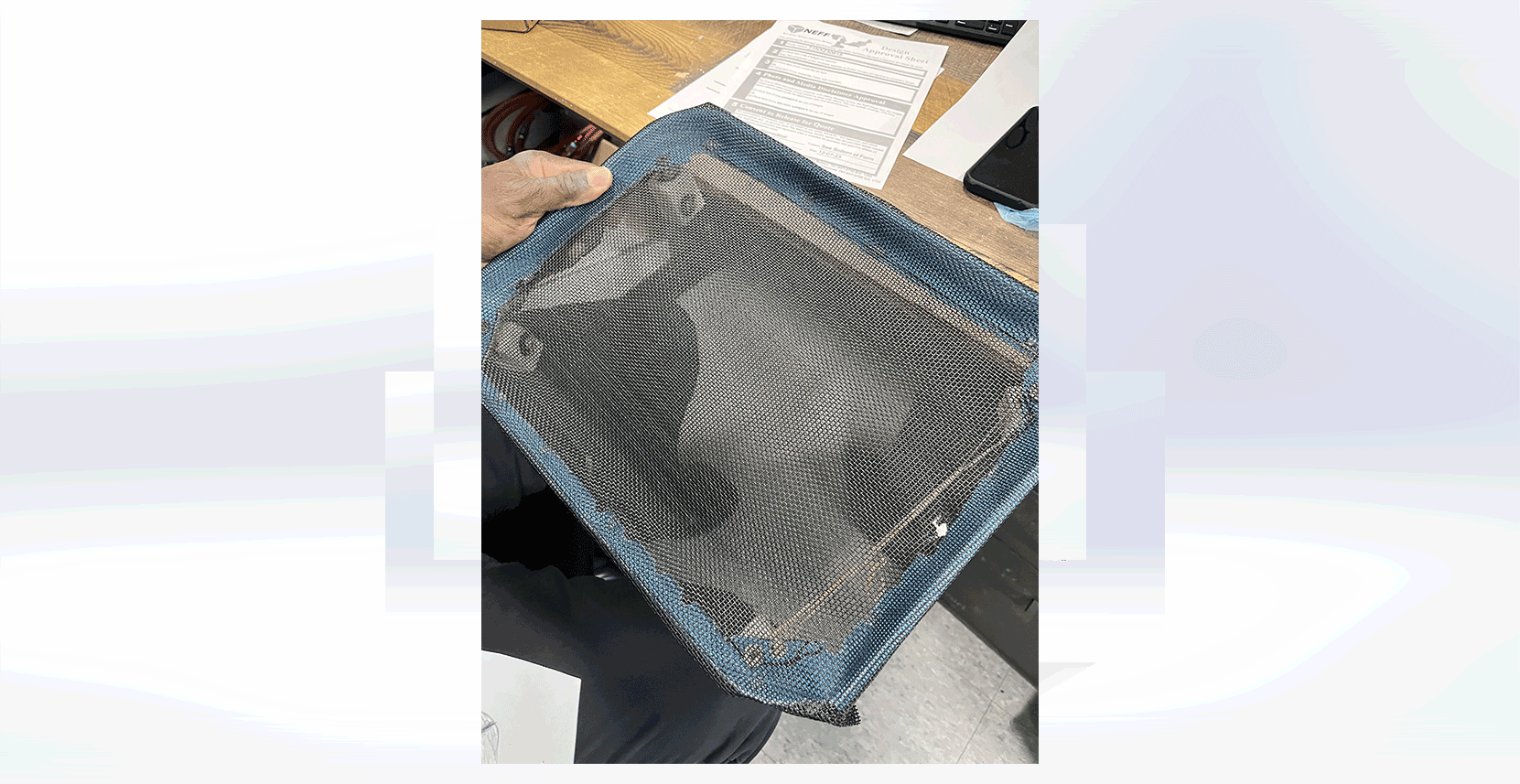

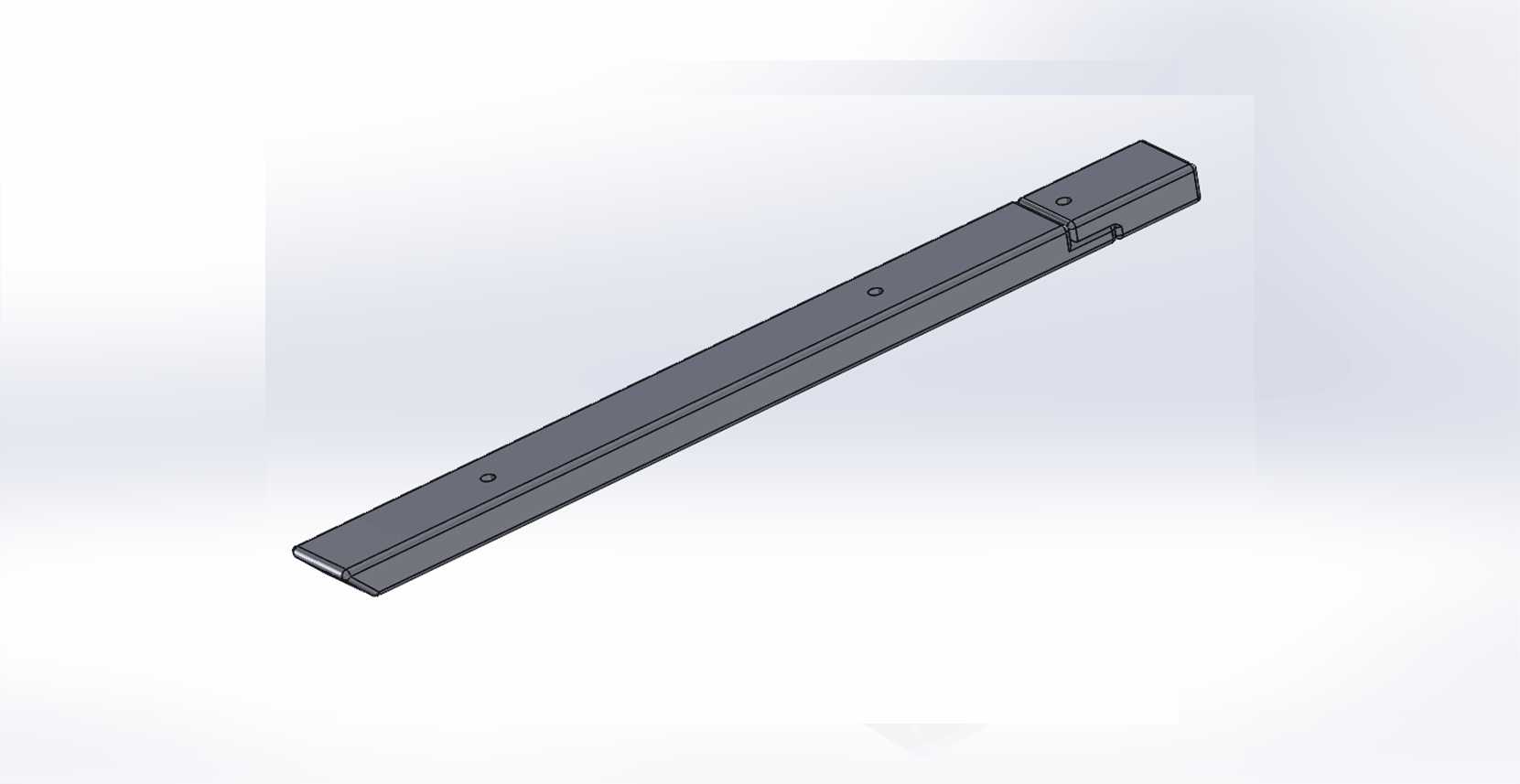

As part of the dryer guard project, a technician requested the creation of a wire mesh tray to be incorporated into the door of the conveyor belt dryer guard. Leveraging surface sweep and revolve techniques, I successfully designed a functional tray featuring wire mesh.

Mesh Tray CAD

Mesh Tray Initial Sketch

Mesh Tray Drawing

Mesh Tray Assembly

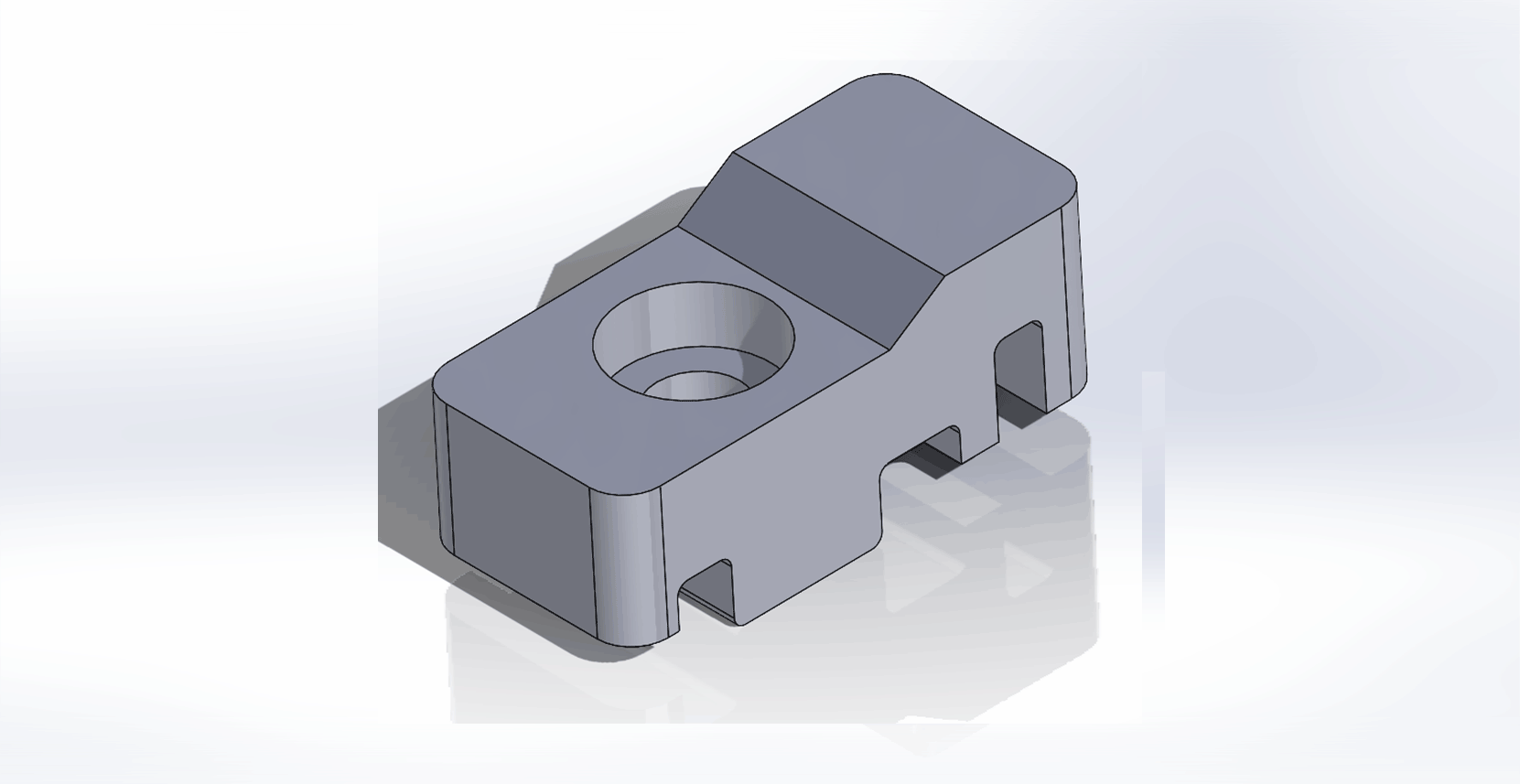

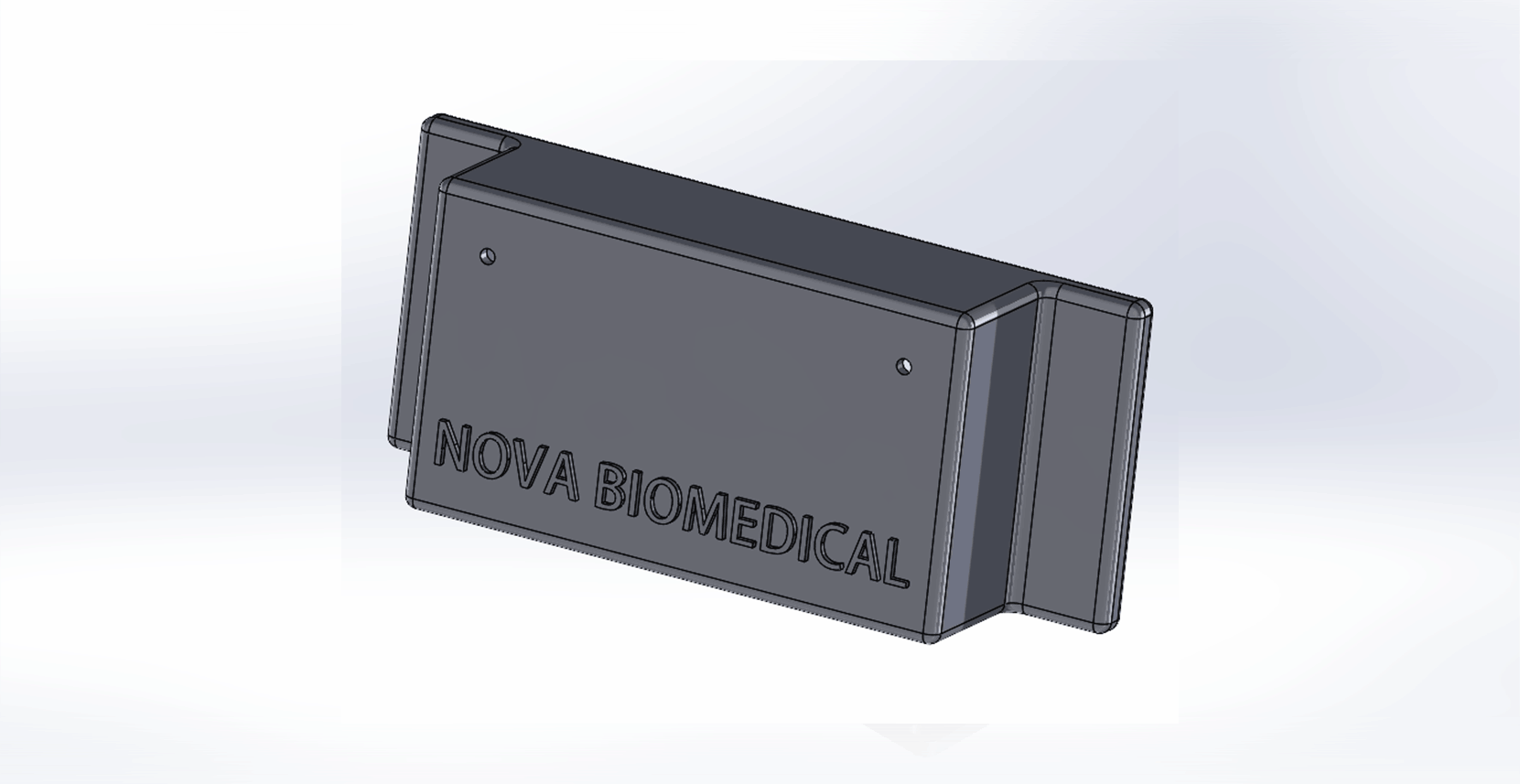

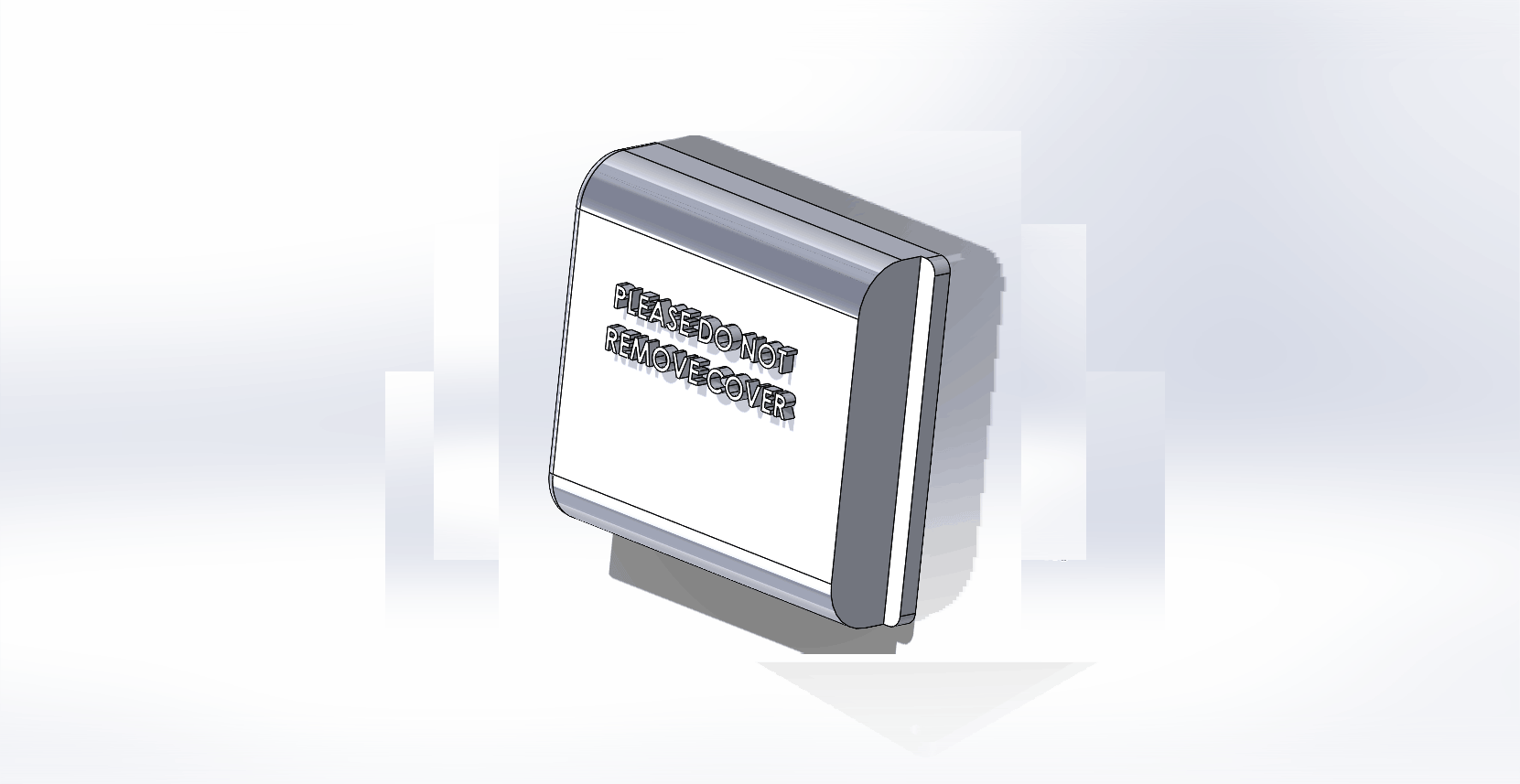

I've compiled drawings and images of components created through 3D printing or machining for the controls room. While these projects may not match the scale of my assembly work, the acquisition of materials and assembly of these fixtures demanded a considerable investment of thorough design and implementation.