Airframe Rocket

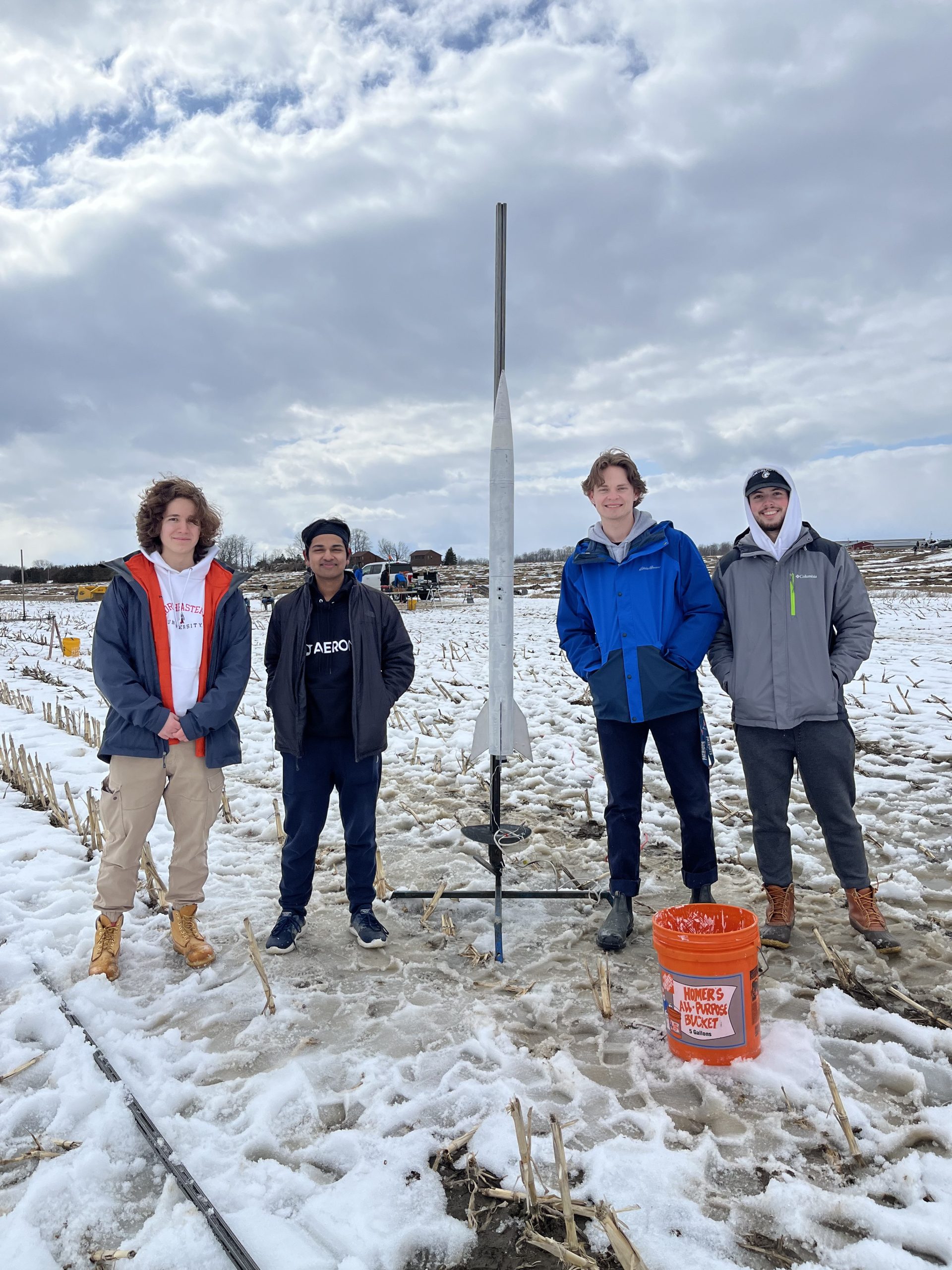

During my second year at Northeastern University, I eagerly joined AerospaceNU, the university's Aerospace Rocketry Club, driven by my lifelong fascination with rockets and inspired by NASA's missions. Within the Intro to Airframe Rocketry Team, I collaborated with fellow engineering enthusiasts, including second-year mechanical engineering students Eddie Sacon and Daniel Nica, under the guidance of Evan Lentz, a third-year chemical engineering student serving as our mentor.

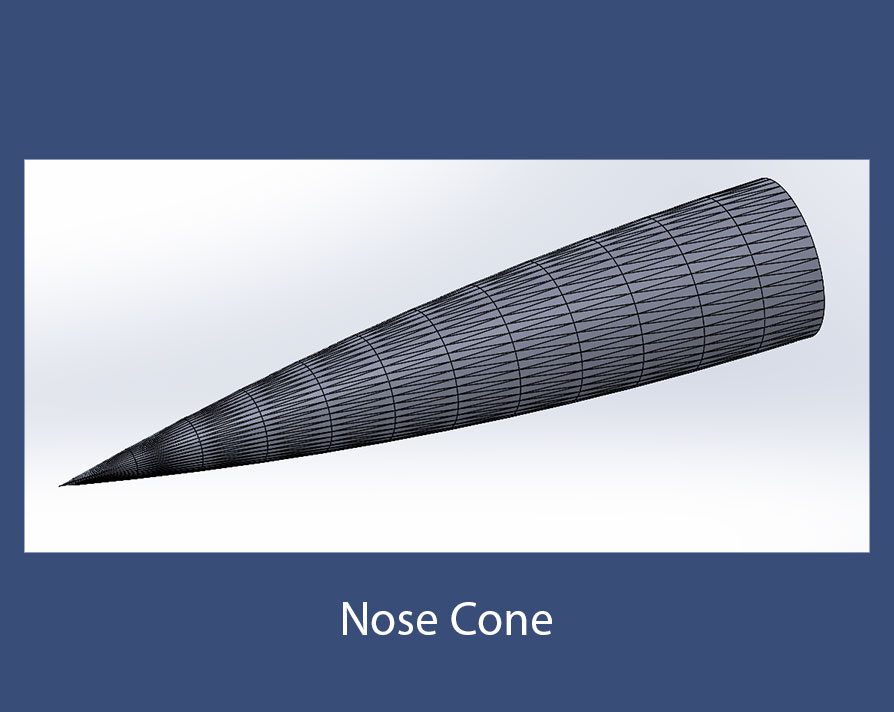

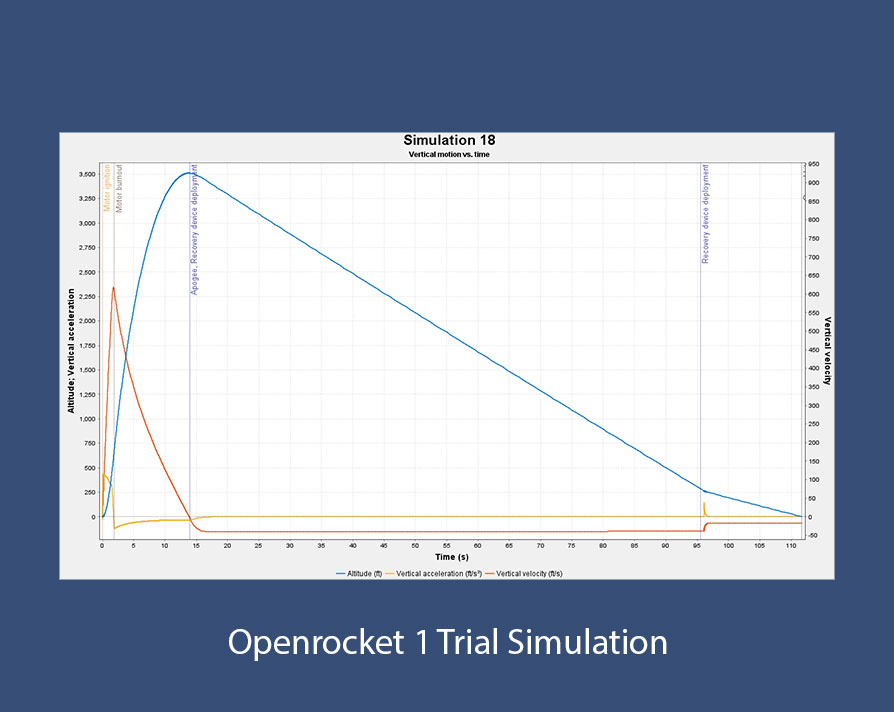

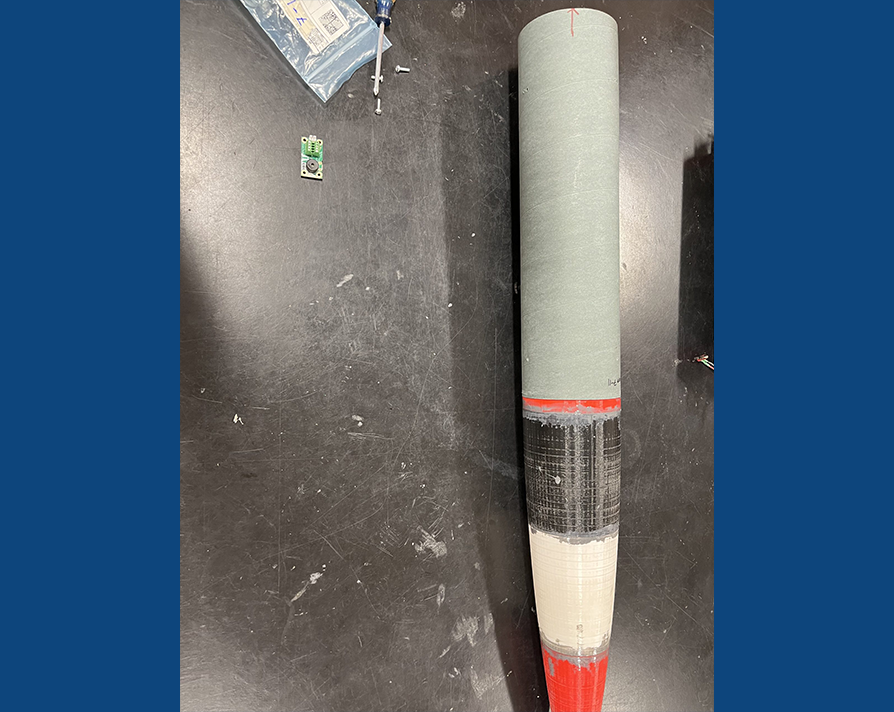

This project unfolded over six months, from October 2022 to March 2023, with a clear mission: design and build a rocket from the ground up and launch it from the St. Albans, Vermont Launch Site. Our goal was to craft a 5-foot rocket with dual deployment capabilities, reaching a peak altitude of 3000 feet, all topped off with an innovative 3D-printed nose cone—a first for our club.

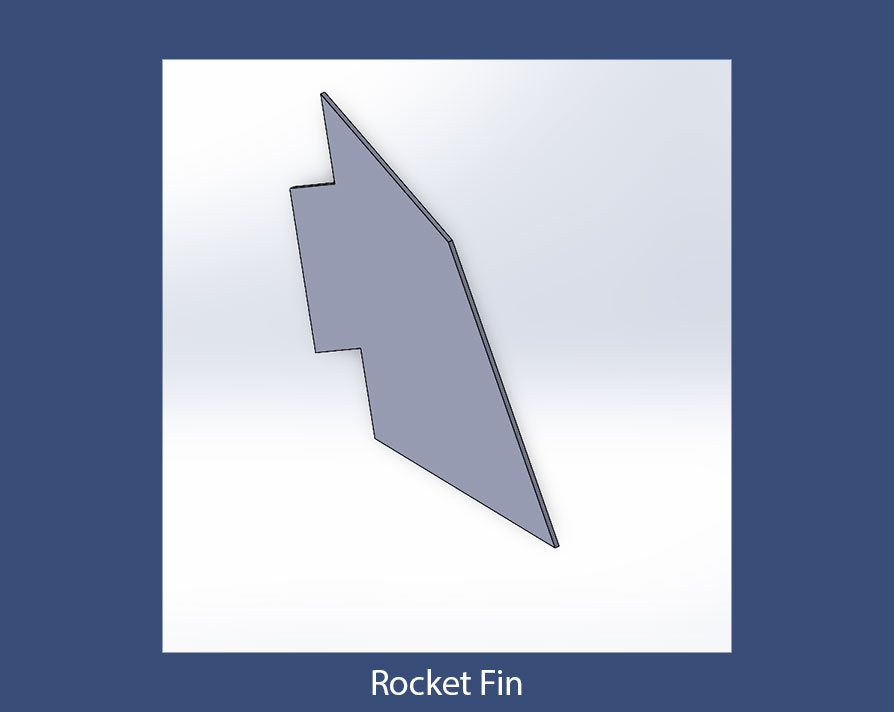

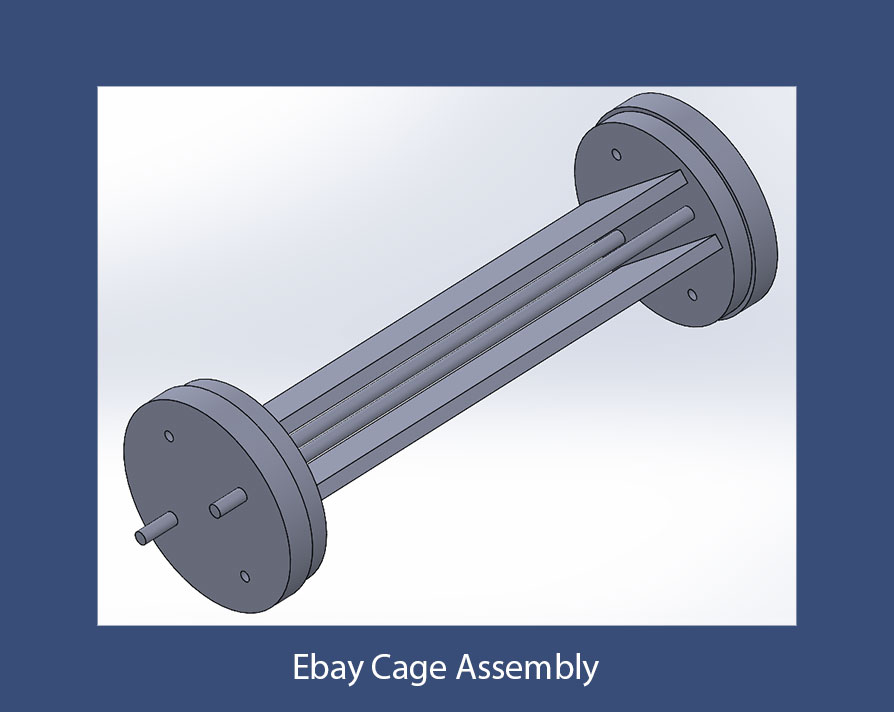

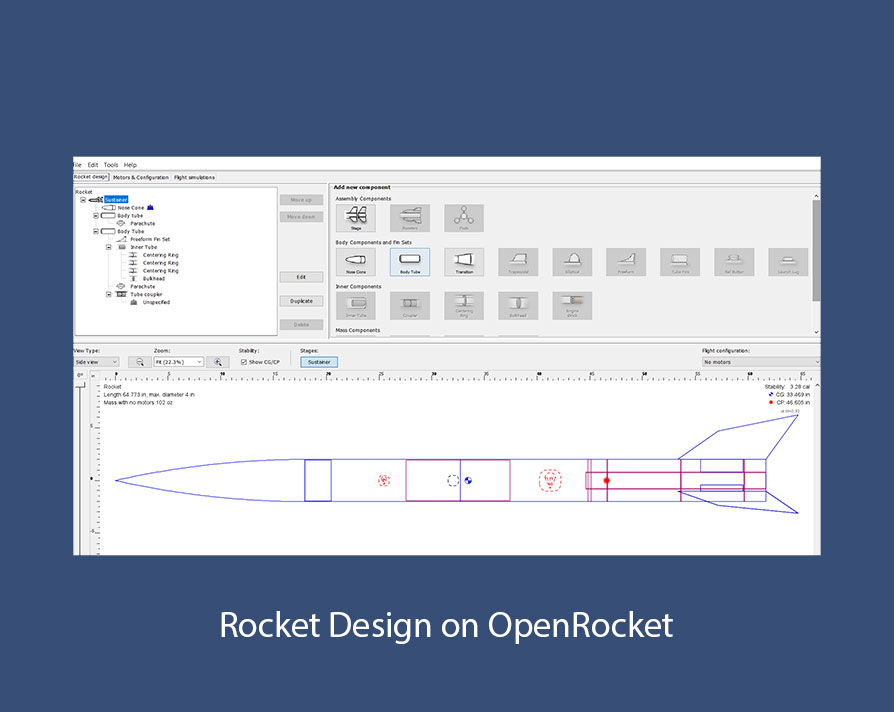

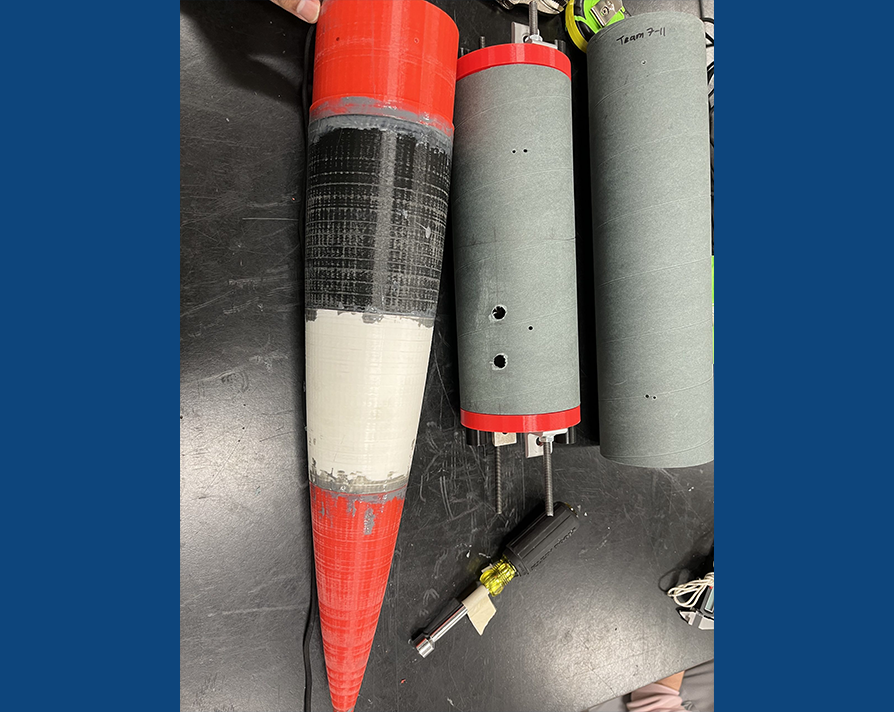

The primary focus of this project revolved around rocket design, with distinct responsibilities assigned to each team member. My role encompassed the design of the rocket's nose cone, blast caps, and fins, while Daniel assumed responsibility for circuitry and simulation tasks, and Eddie oversaw the construction of the Ebay cage, body tube, and coupler. The left-hand images displayed below showcase a selection of CAD models created using SolidWorks, instrumental in shaping our rocket's design, while the right-hand images depict simulations of our rocket's performance, executed through OpenRocket.

Skills: 3D Modeling (SolidWorks), Simulation (OpenRocket)

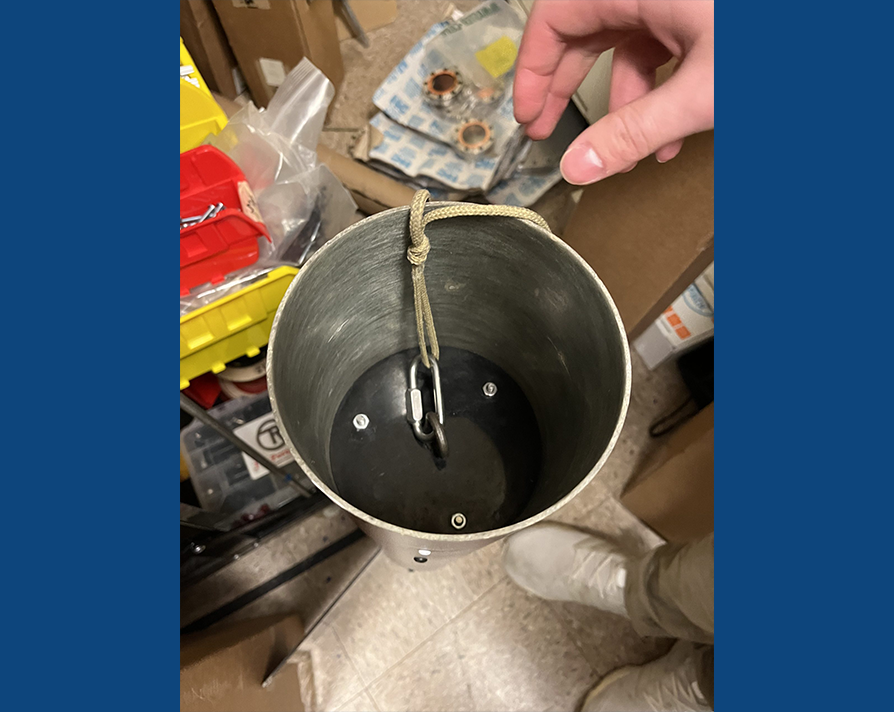

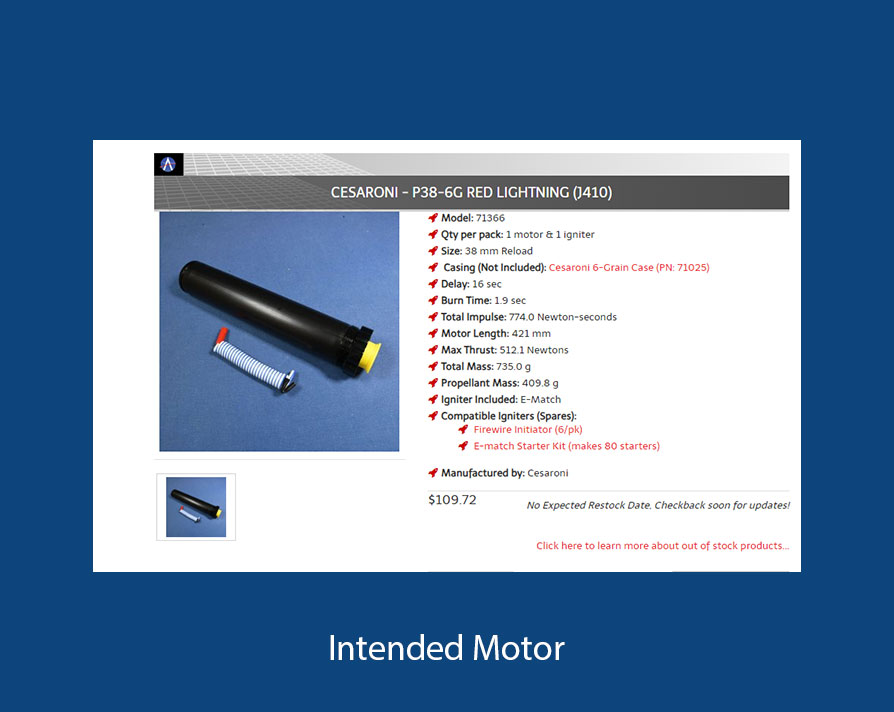

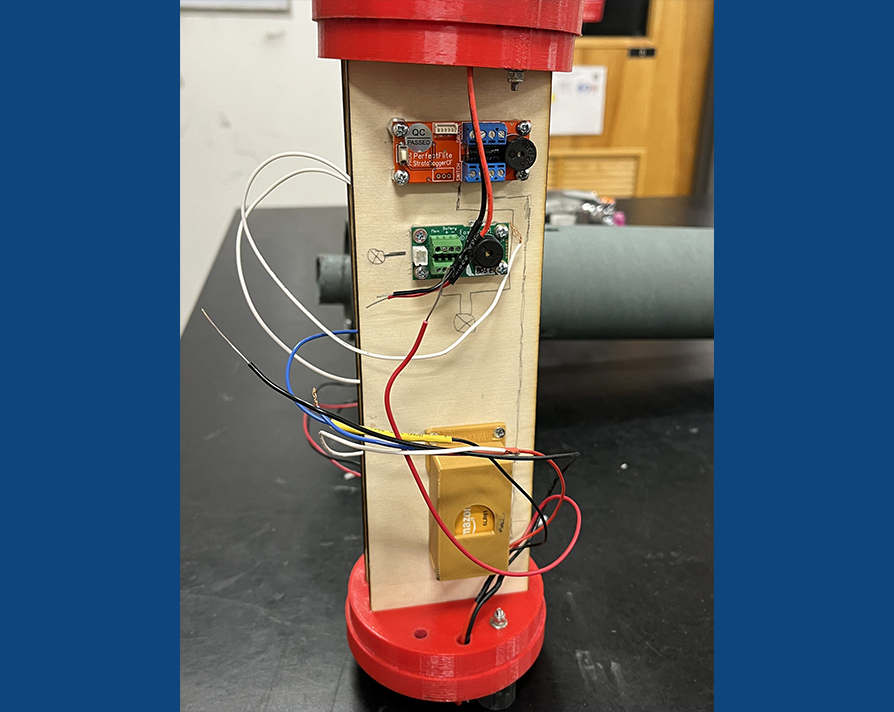

Following the completion of our rocket's component designs, we initiated the assembly phase. This involved procuring motors, body tubes, parachutes, and electronic components, as well as precision laser-cutting of wooden boards to create fins and eBay cage slots. We also employed Fused Deposition Modeling (FDM) 3D printing to fabricate the nose cone and other vital components.

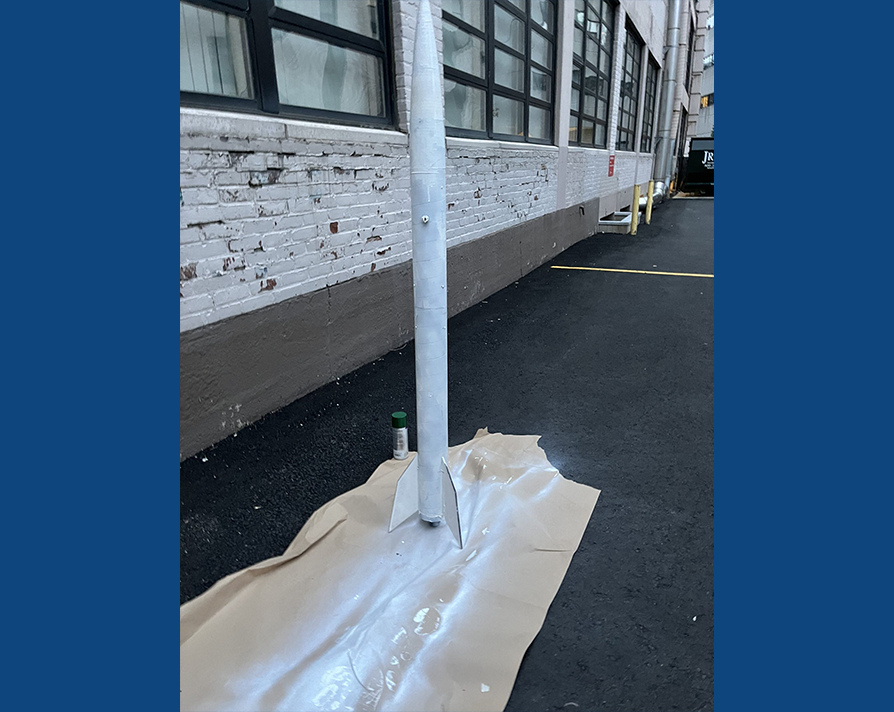

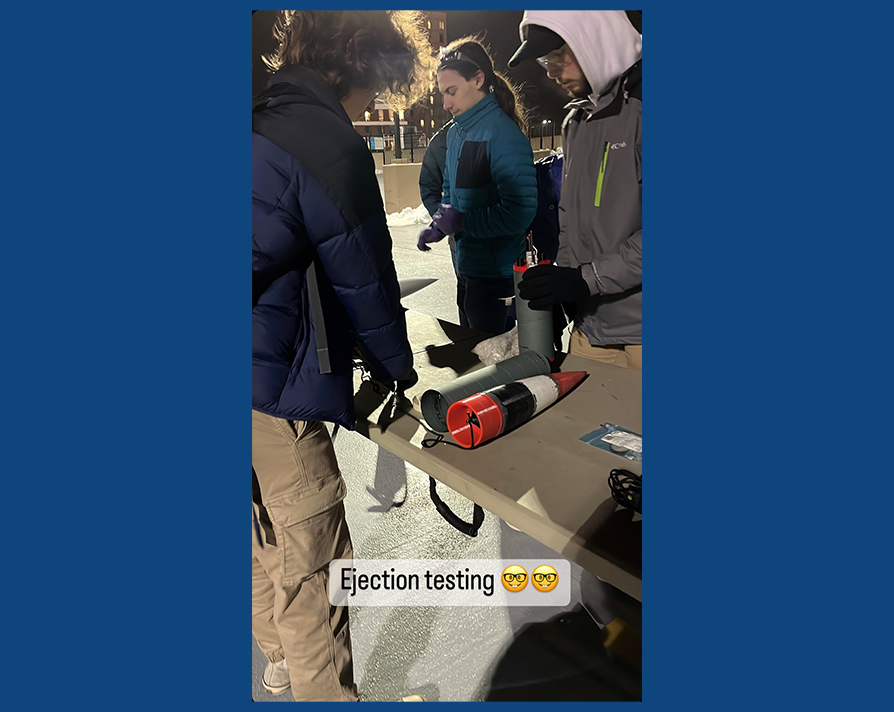

Throughout this process, periodic safety assessments conducted during our Design, Simulation, and Construction (DSC) Safety meetings led to occasional redesigns of specific elements. As the majority of the rocket took form and we safely introduced flammable materials, we carried out ejection testing with the university's approval on the school's parking garage rooftop. This testing ensured the proper connection and readiness for launch before the official launch date. Our commitment to regular meetings, initially on a weekly basis and later intensifying to two or three sessions per week as the launch date approached, fostered a climate conducive to effective progress and collaborative excellence. Finally, the rocket underwent a white paint application to emulate the appearance of rockets launched by NASA and JetBlue.

Skills: Tapping & Threading, Drilling, Sanding, 3D Printing, Laser Cutting, Soldering & Wiring

Following six months of dedicated effort, the moment arrived for our rocket launch. Prior to reaching the launch site, we disassembled the rocket to ensure it would fit inside our vehicle. Upon arrival, we meticulously assembled the rocket, ensuring the correct screws and motor were in place. Subsequently, we navigated the challenging terrain, reaping the necessary approvals, and, at last, initiated the launch.

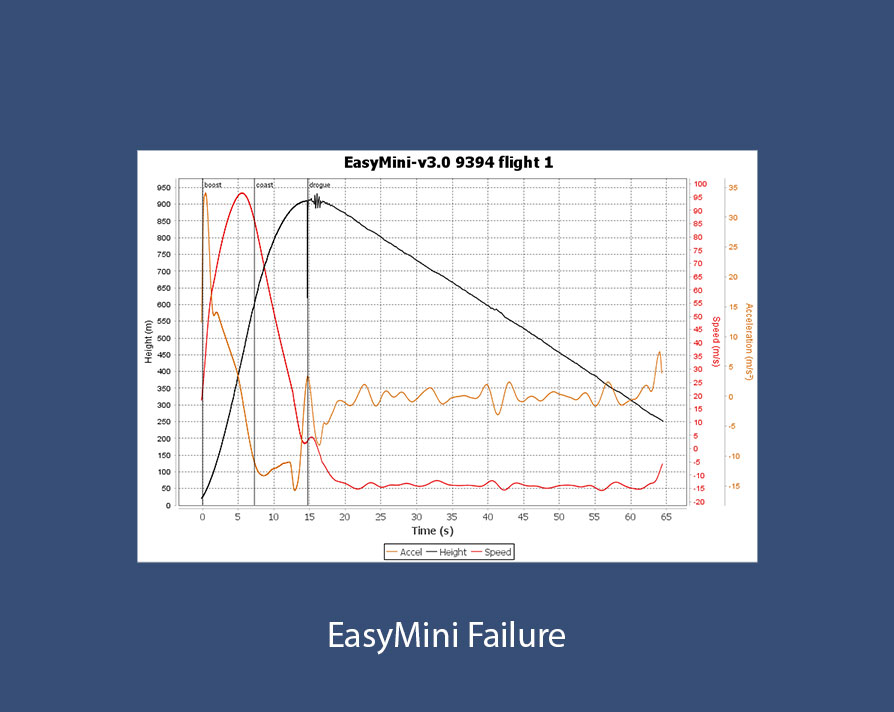

Regrettably, our rocket experienced an in-flight explosion attributed to a motor failure. However, it's important to note that such occurrences are not uncommon in the realm of engineering, and this setback did not render our entire project a failure. In fact, we found a silver lining in this incident as it brought to our attention that our rocket shared the same color as the clouds and snowy ground that day. Had the rocket continued its trajectory and landed further away, locating it would have posed a significant challenge.

Despite this setback, the experience proved immensely enjoyable. Witnessing the culmination of our hard work, participating in the entire process, traveling to the launch site, and observing other teams launch their rockets added a unique and rewarding dimension to our journey.

In hindsight, this project has been a thoroughly enjoyable journey, marked by its novelty and the camaraderie it fostered. Engaging in a captivating after-school endeavor in college, particularly one involving rockets, has been an incredible experience. The transition from digital design work to witnessing the rocket we collectively crafted soar into the skies over Vermont felt surreal and immensely rewarding. I had the privilege of connecting with fellow aspiring engineers and acquiring valuable skills that I might not have otherwise obtained. Moreover, this project ignited a newfound passion for space exploration within me, motivating my continued involvement in other exciting initiatives at AerospaceNU and NURover as I embark on my third year.