Myowearable Sleeve

In my freshman year at Northeastern University, I engaged in a collaborative effort with four

fellow engineering students within the framework of our Cornerstone Engineering I-II course to

develop a medical apparatus. My primary role in this project focused on the electronics and

sleeve design aspect.Our conceptualization centered on the innovation of a sleeve-mounted

medical device designed for the monitoring of electrical stimulation in nearby musculature,

employing surface electromyography (sEMG) sensors for data acquisition. This innovative

device serves the purpose of alerting the user to the onset of muscle fatigue. For the full project

narrative, please continue reading the subsequent sections.

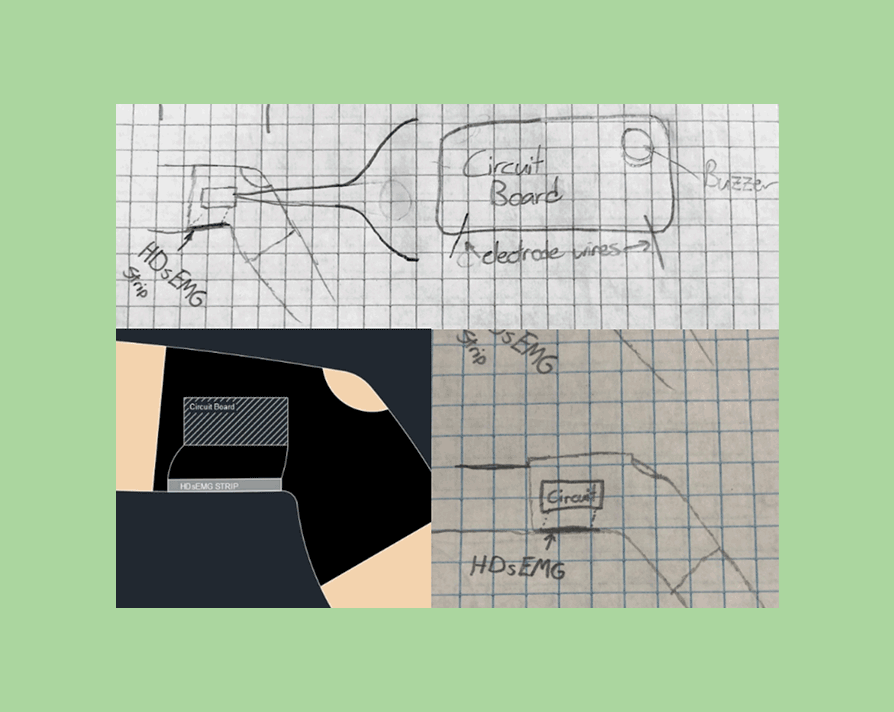

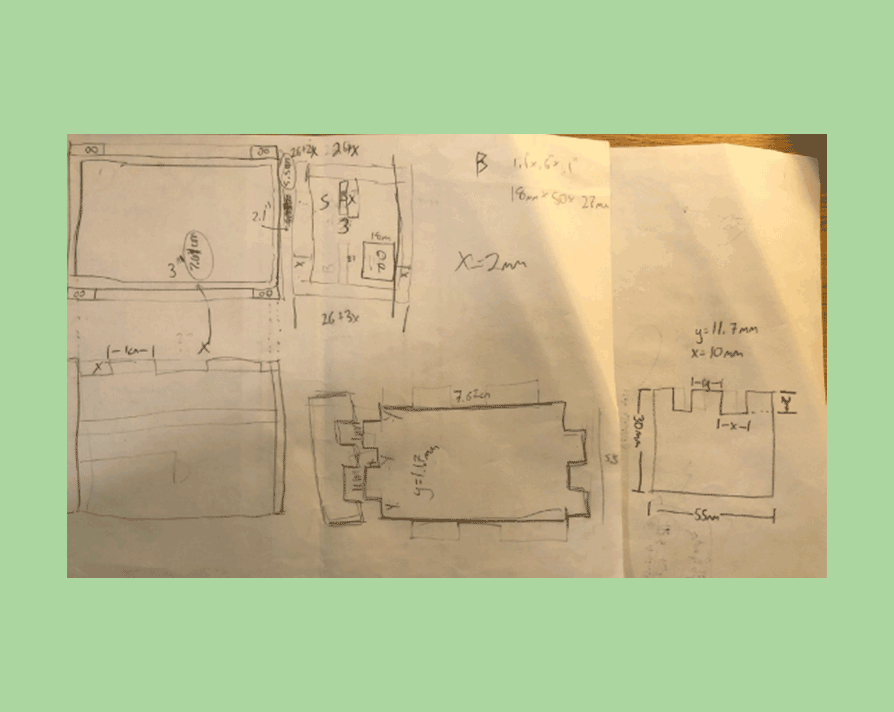

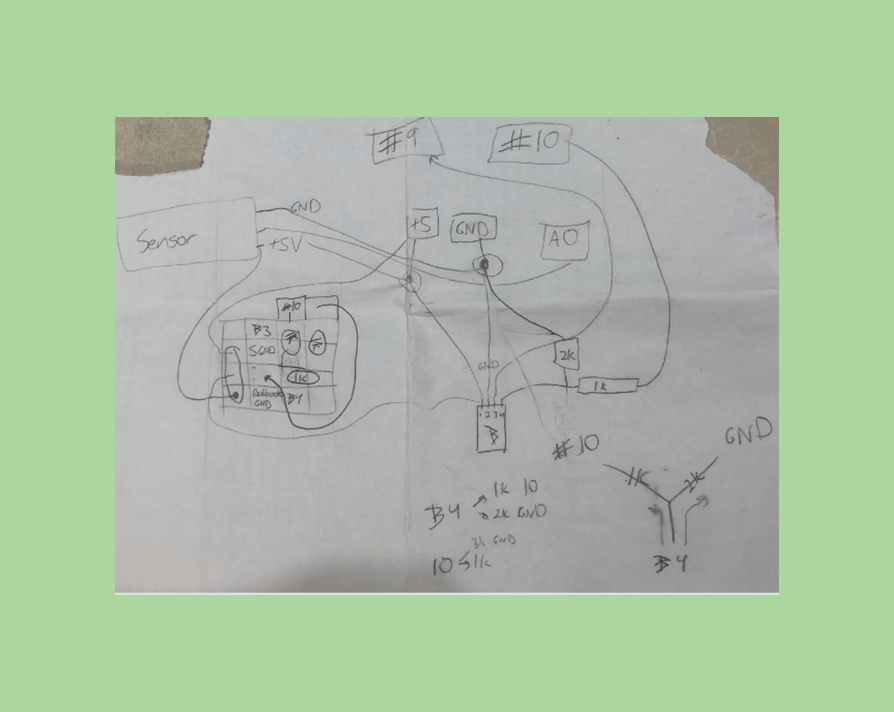

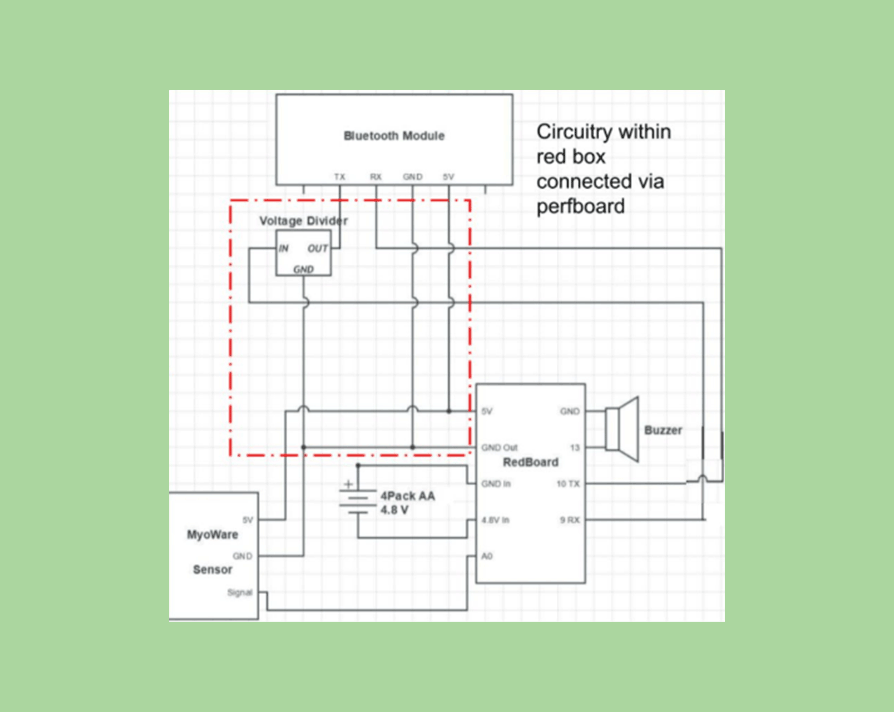

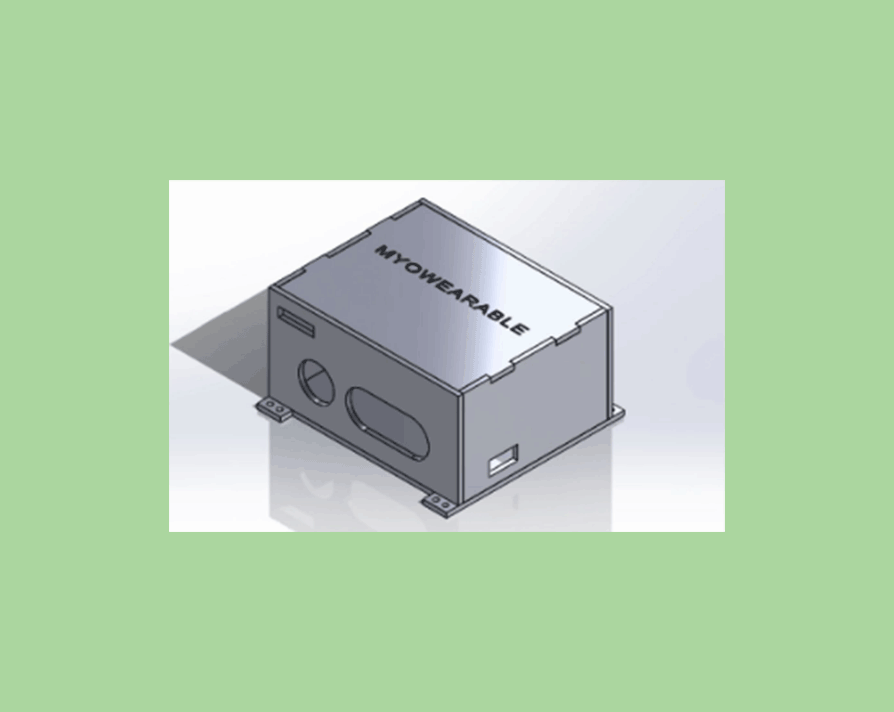

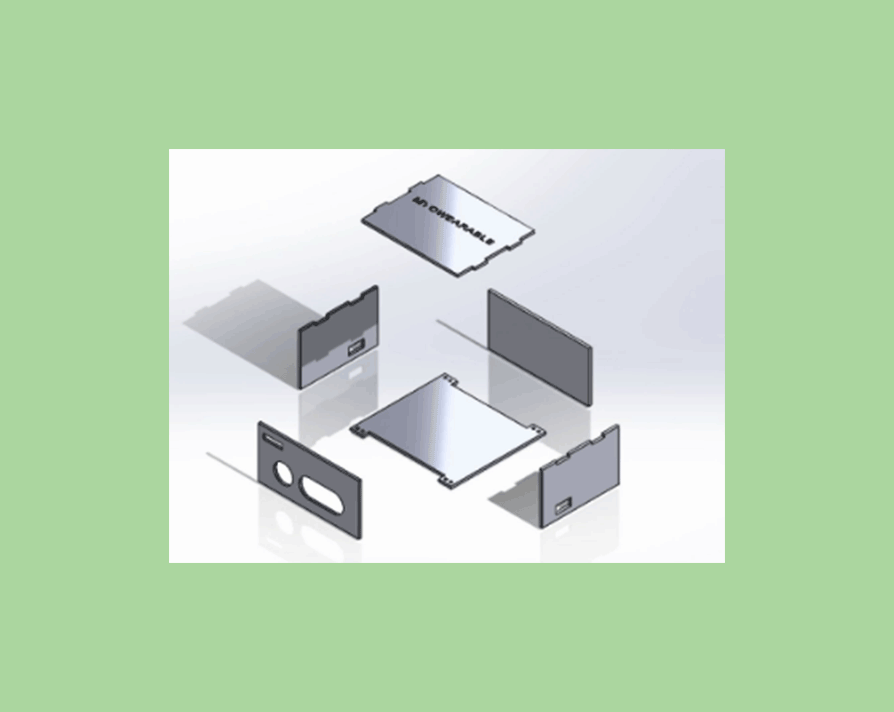

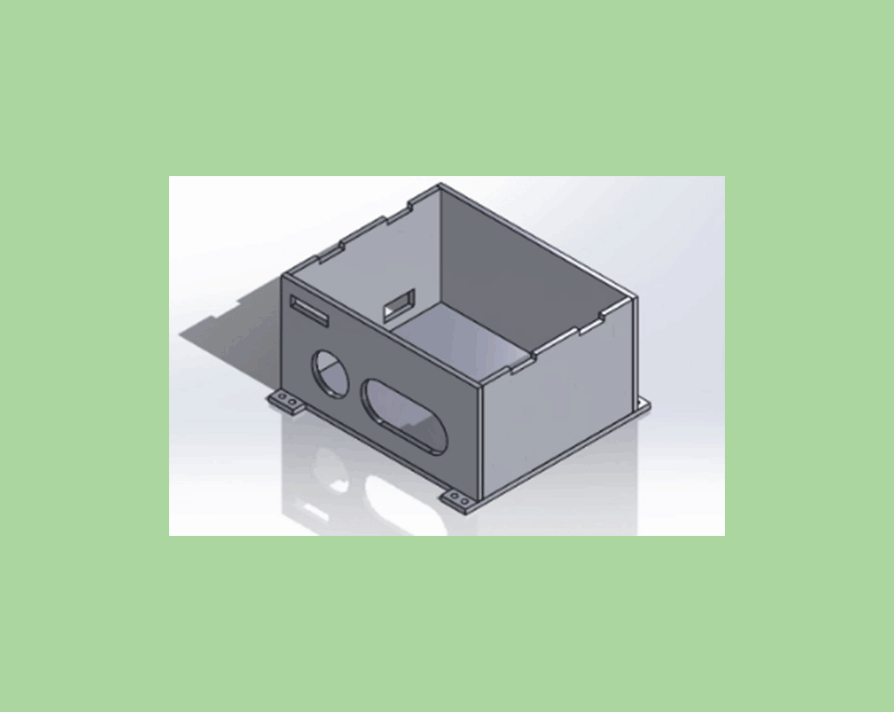

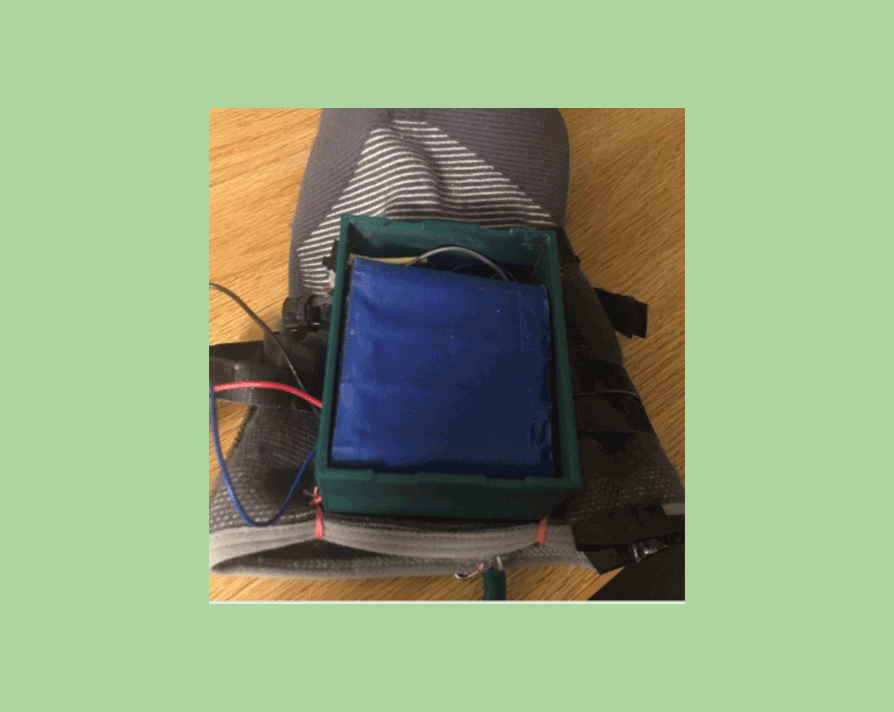

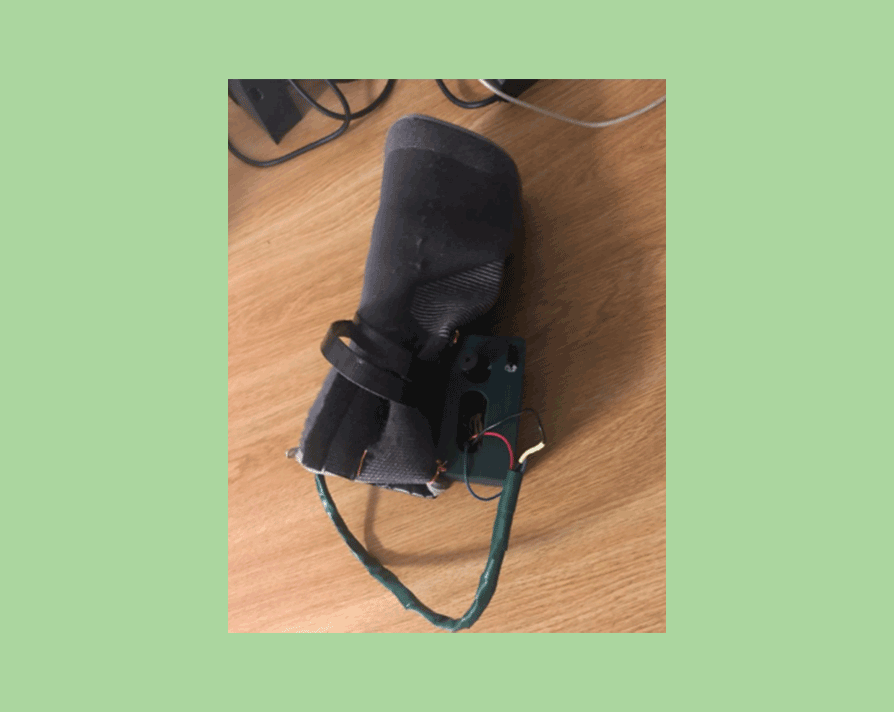

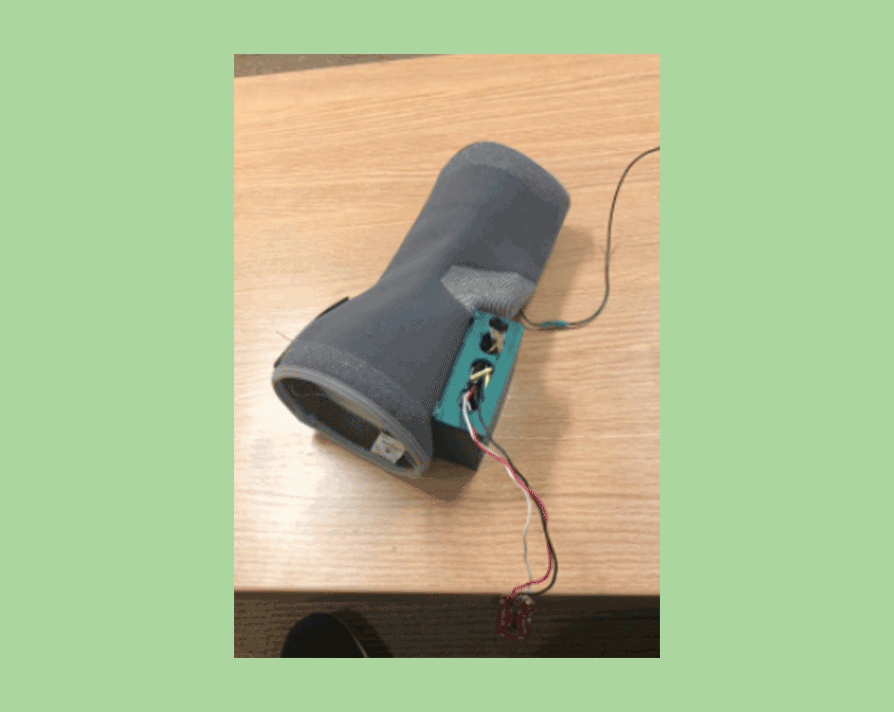

We initiated the design process with the generation of preliminary sketches detailing the placement of the sleeve, the circuitry layout, and the wire storage arrangement. Initially, we contemplated siting the sleeve on the knee; however, we soon recognized the potential testing challenges posed by varying thigh sizes and the impracticality of passing the sleeve through footwear. Consequently, we opted to shift our focus to arm placement, considering the accessibility and adjustability of the sleeve. In tandem, we produced (CAD) drawings for a casing to house the circuitry, accompanied by a comprehensive circuit diagram for the electrical layout.

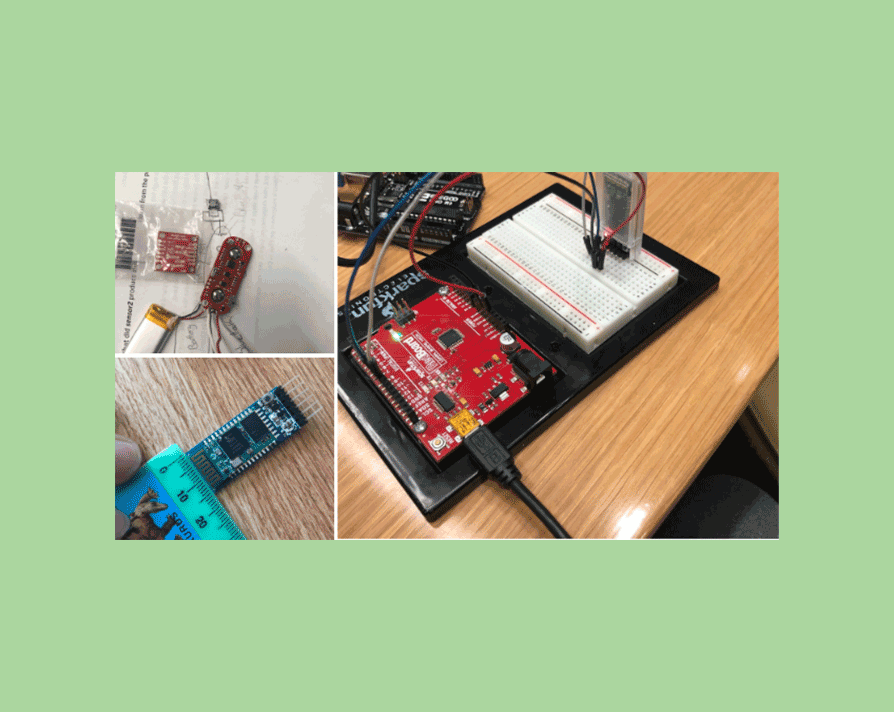

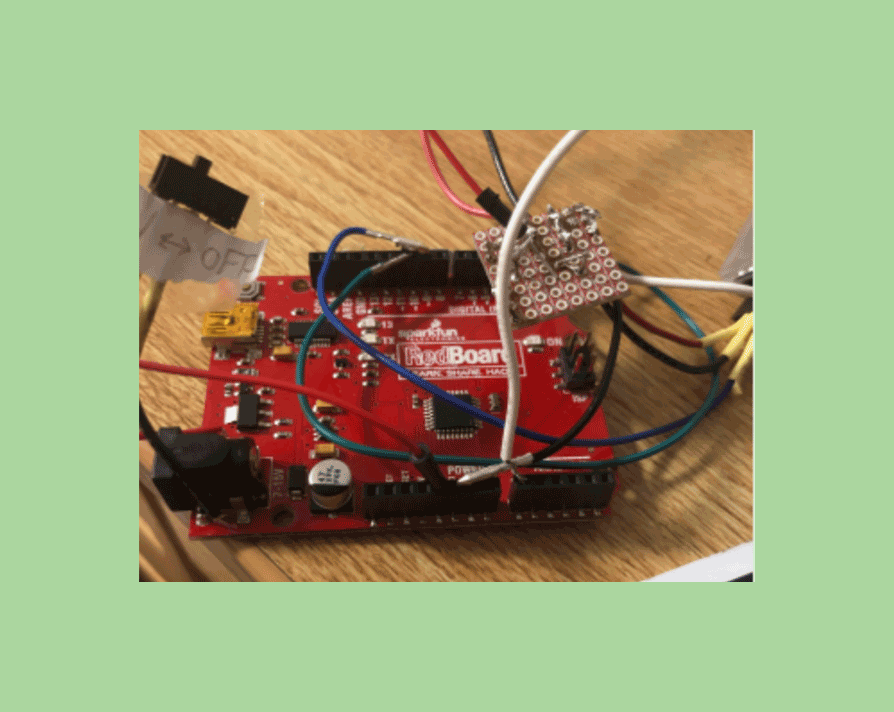

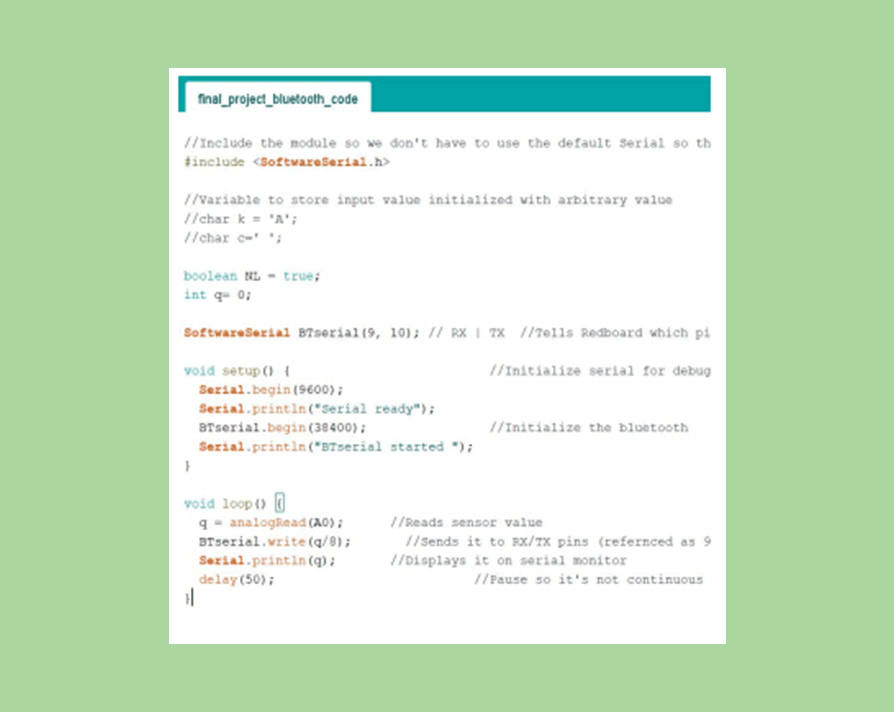

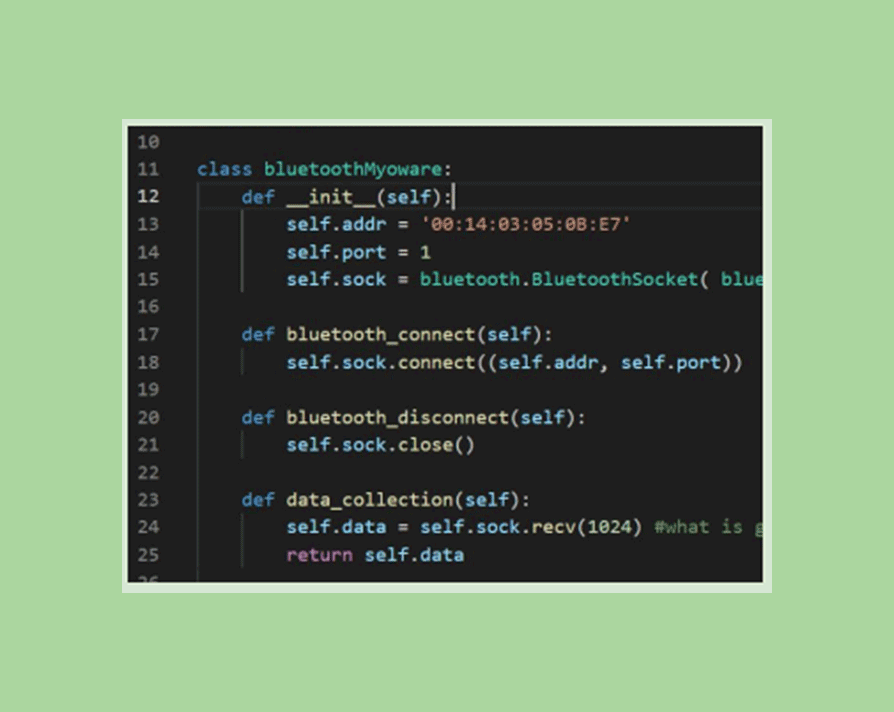

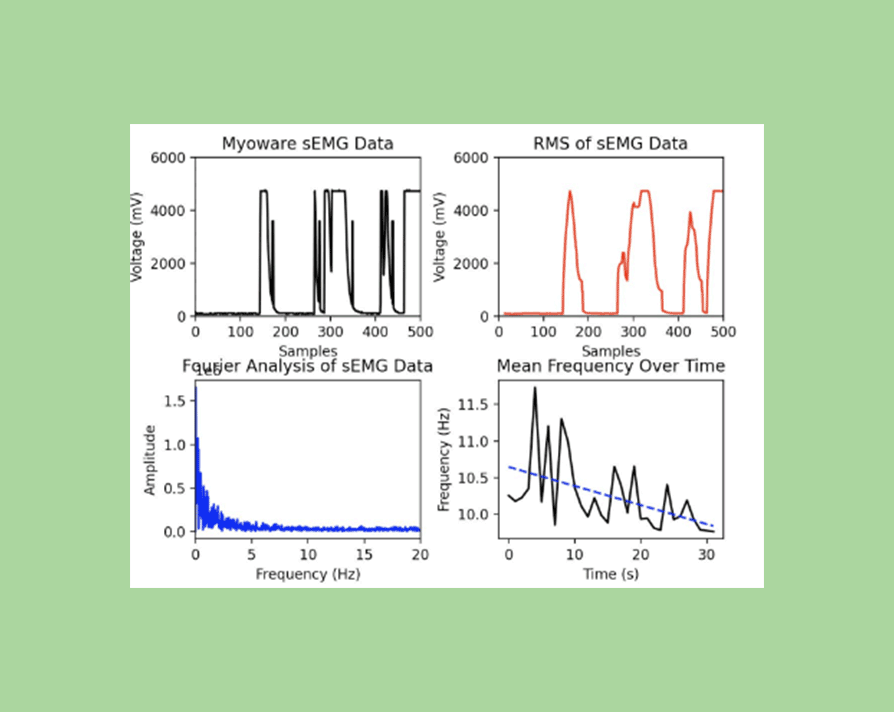

Our hardware setup included an sEMG sensor equipped with a visual indicator that illuminated each time a muscle was flexed. We established the necessary connections, first linking the sensor to the circuit perf board and subsequently integrating the Bluetooth module. Within the Arduino Integrated Development Environment (IDE), we formulated the requisite code to enable the functionality of the EMG sensor. Furthermore, we employed Arduino to generate AT commands, configuring the Bluetooth module as needed. The remaining programming was executed in Python, facilitating the transmission of sensor data to the Bluetooth module and its utilization for graph generation.

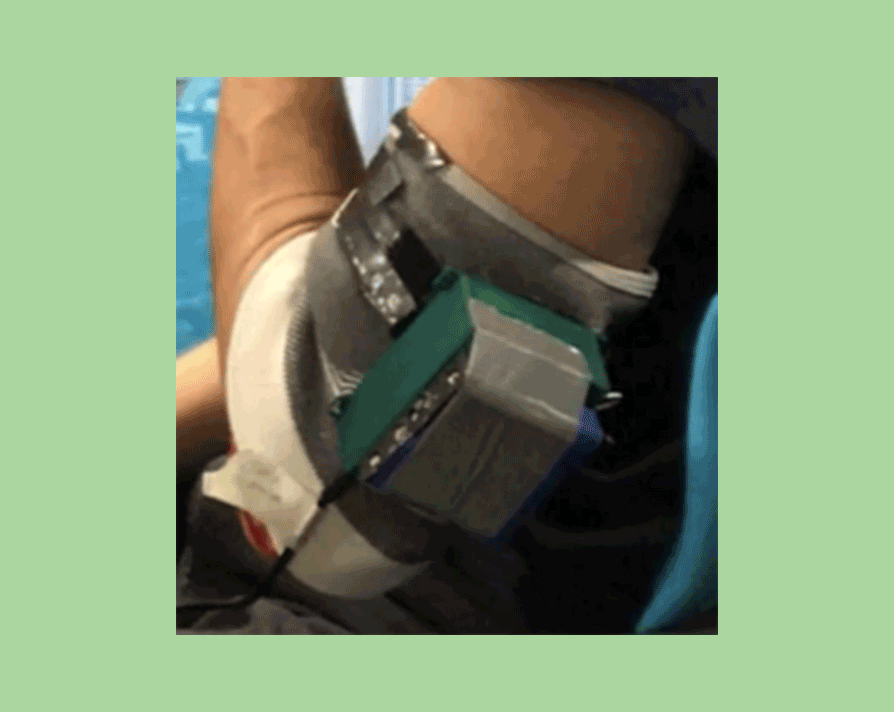

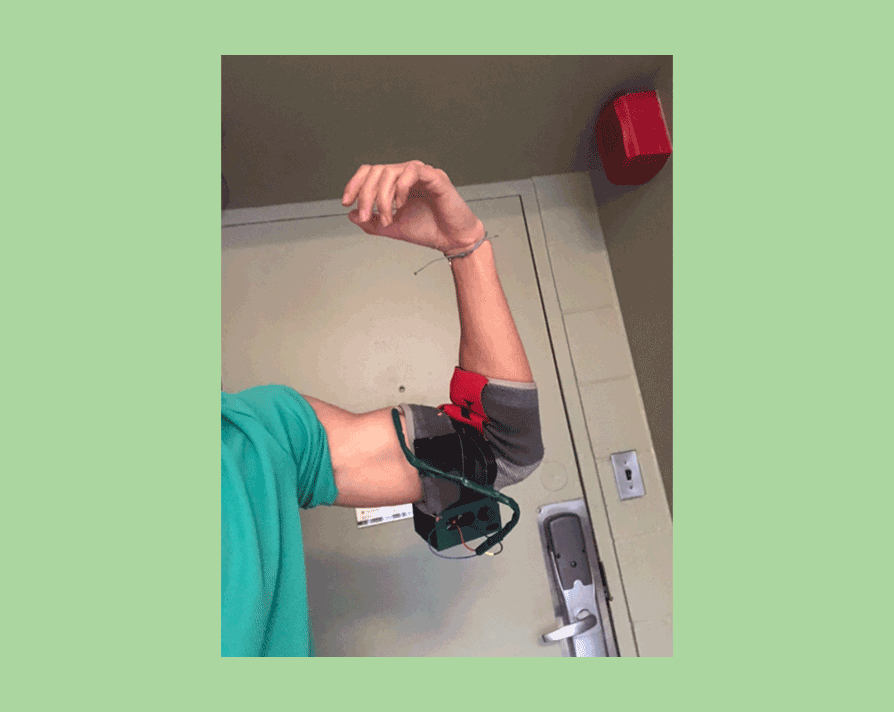

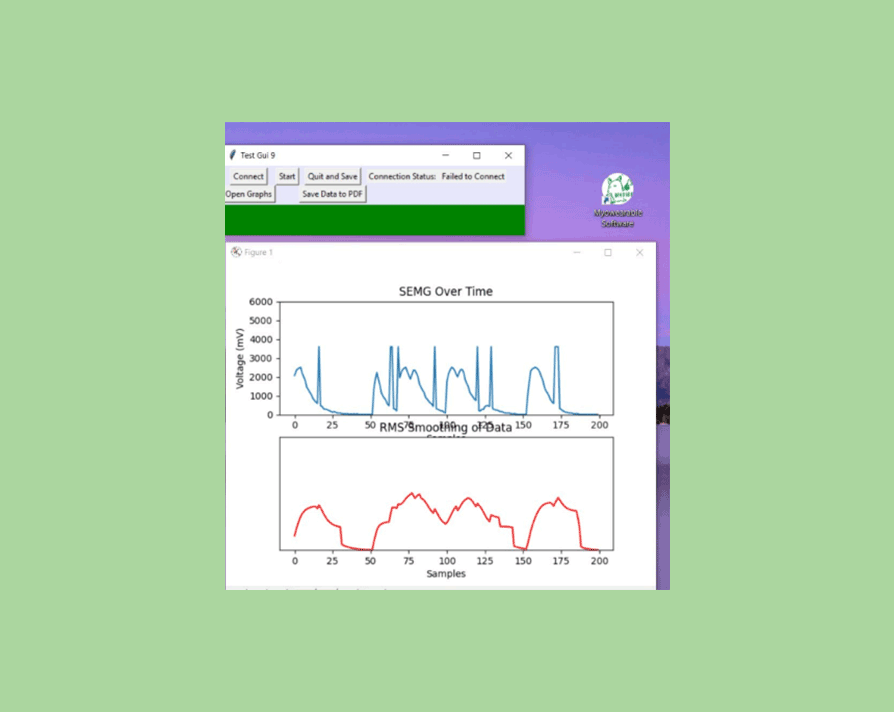

This stage involved assembling the sleeve and wiring through sewing, soldering, and Velcro strapping for adjustability. It also marked the code's finalization and the creation of a graphical user interface (GUI) for data display.

We presented our carefully designed myowearable sleeve—a creative solution shared with peers and engineers across the country. Dive into the final paper, an engaging development video, and a lively PowerPoint presentation, capturing the journey and story behind our advanced sleeve.

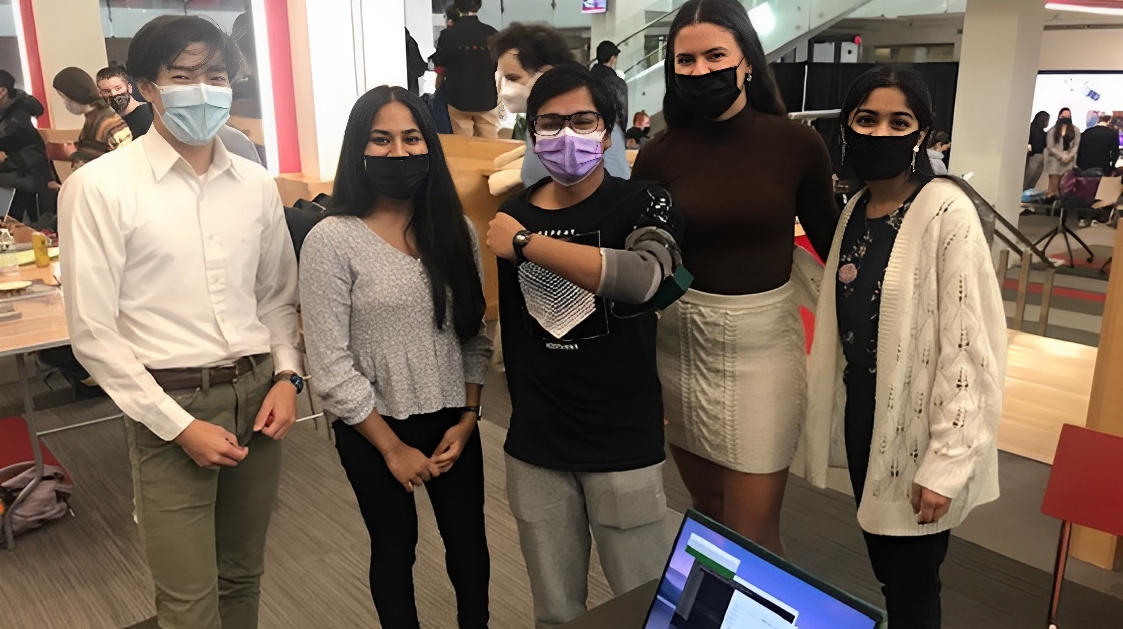

Presented here is a compilation of photographs capturing moments from our participation at the ASEE 2022 Conference in Minneapolis, Minnesota. This event provided us with a valuable opportunity to showcase our work and engage in networking activities.

This medical device project offered a full spectrum of engineering experience, from inception to completion. I collaborated with a skilled team of engineers, presented my work at a conference, and gained essential life skills in budgeting, networking, and presentation. It also advanced me toward my mechanical engineering career goal.

Team Members